Pressure relief valve automatic assembly equipment

A technology for assembling equipment and pressure relief valves, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problem of being unable to meet the development trend of high efficiency, high quality and low cost, difficult to choose between processing output and processing cost, and no automation of operation mode Equipment and other issues, to achieve the effects of labor saving, high degree of automation, and high degree of functional integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

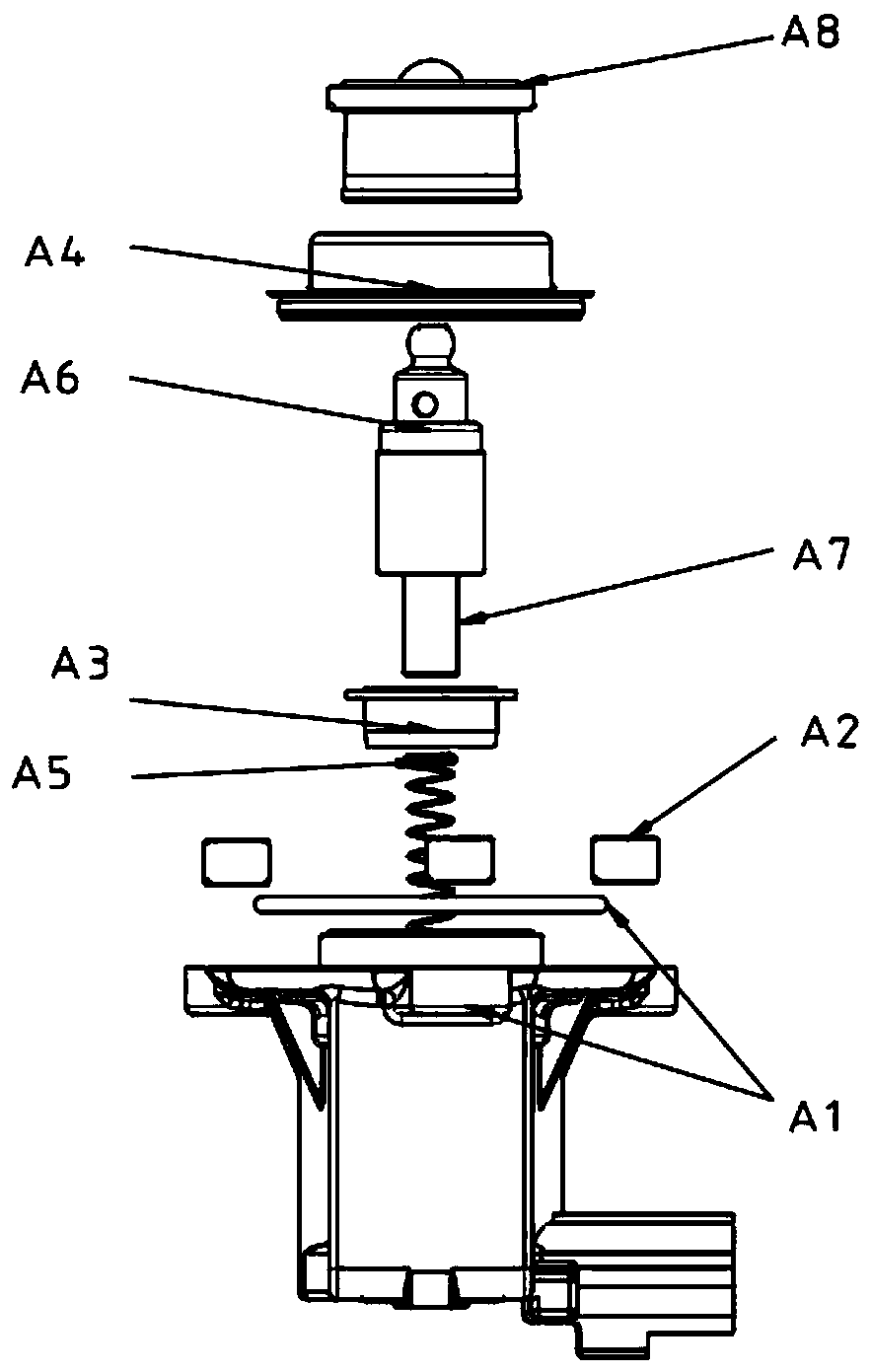

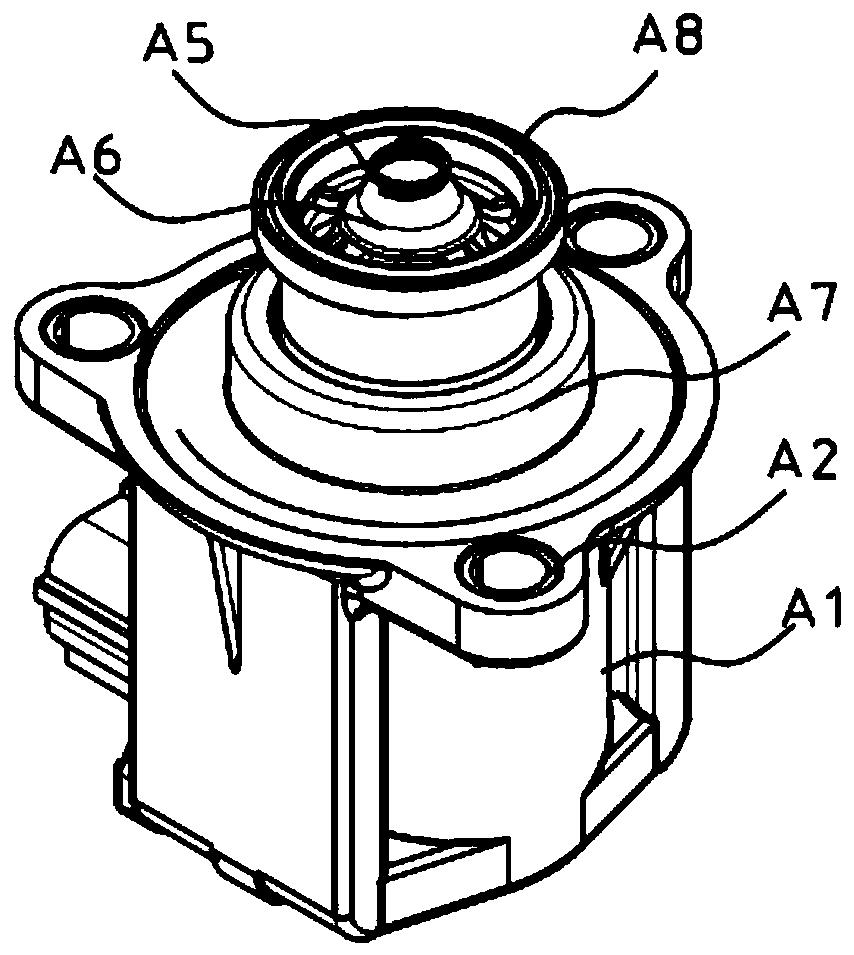

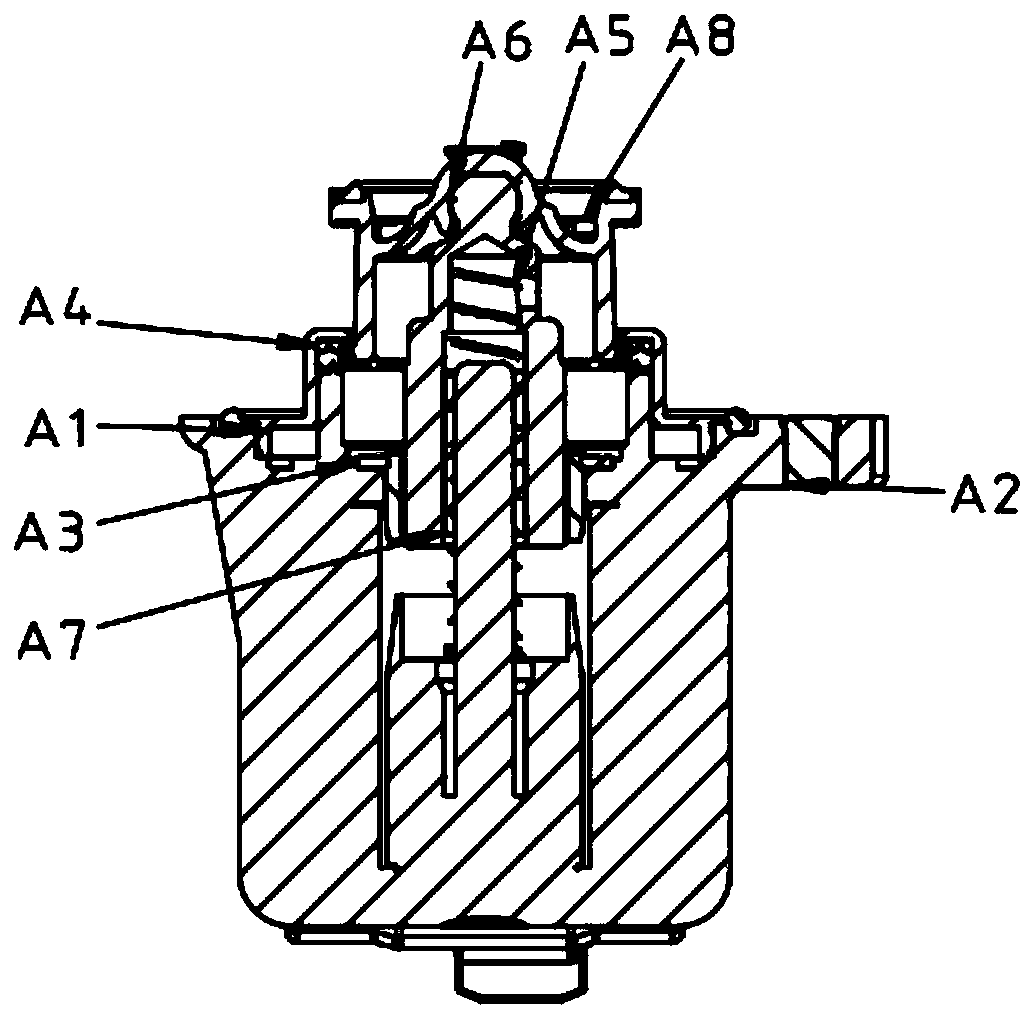

[0084] Embodiment: a kind of pressure relief valve automatic assembly equipment, such as Figures 2.1 to 2.4 As shown, it includes a frame 1 and a pressure relief valve main assembly line 2 and a moving valve core assembly assembly line 3 located on the frame;

[0085] The main assembly line 2 of the pressure relief valve includes a main turntable 21, and a plurality of valve body carriers 211 are arranged on the main turntable. Device 22, round washer assembly device 23, fixed ring assembly device 24, side cap assembly assembly device 25 and spring assembly device 26;

[0086] Such as Figures 2.1 to 2.4 as shown and as Figure 7As shown, the moving spool assembly line 3 includes an auxiliary turntable 31, the auxiliary turntable is provided with a plurality of moving spool carriers 311, and the moving spool assembly line also includes a moving spool feeding device 32, Moving spool turning device 33, shaft sleeve assembling device 34, moving spool inner hole diameter testi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com