Horizontal directly-linked thyristor valve block

A technology of thyristor valve and direct connection, which is applied in the direction of reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve the problems of unsatisfactory structural stability, unsatisfactory construction cost and line loss, etc., to achieve increased stacking The effect of quantity, guaranteed stability and uniform distribution of electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

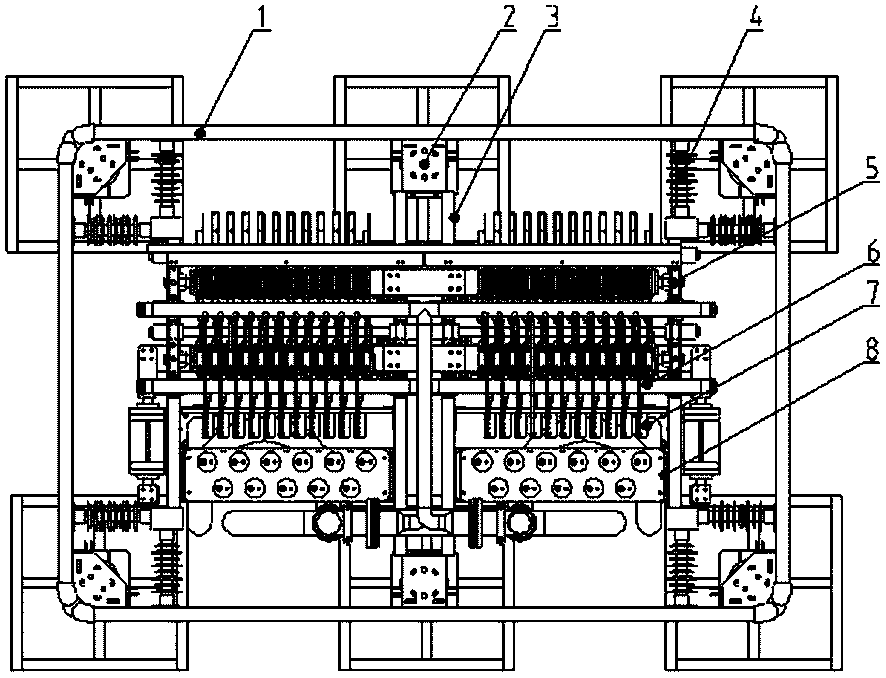

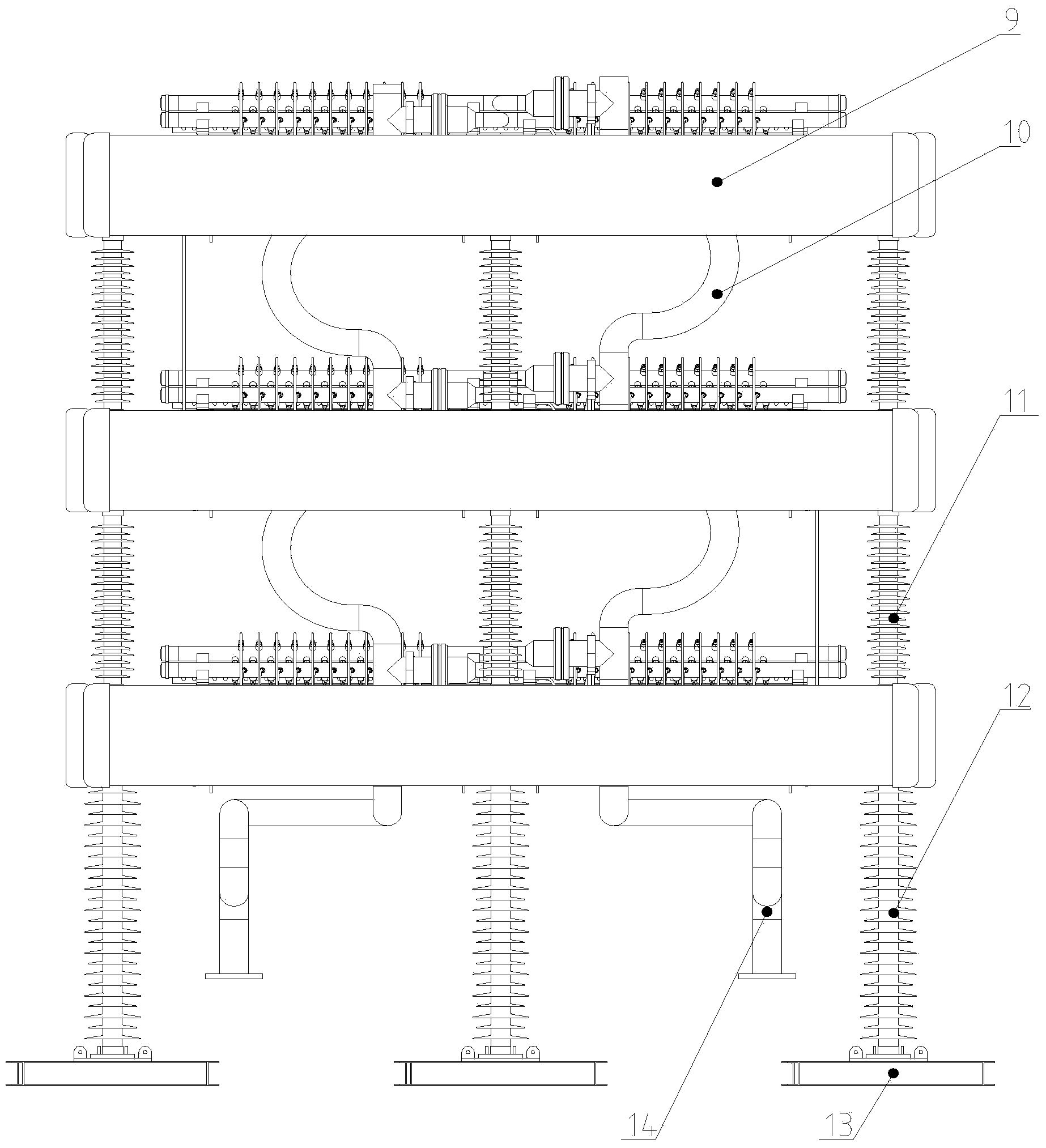

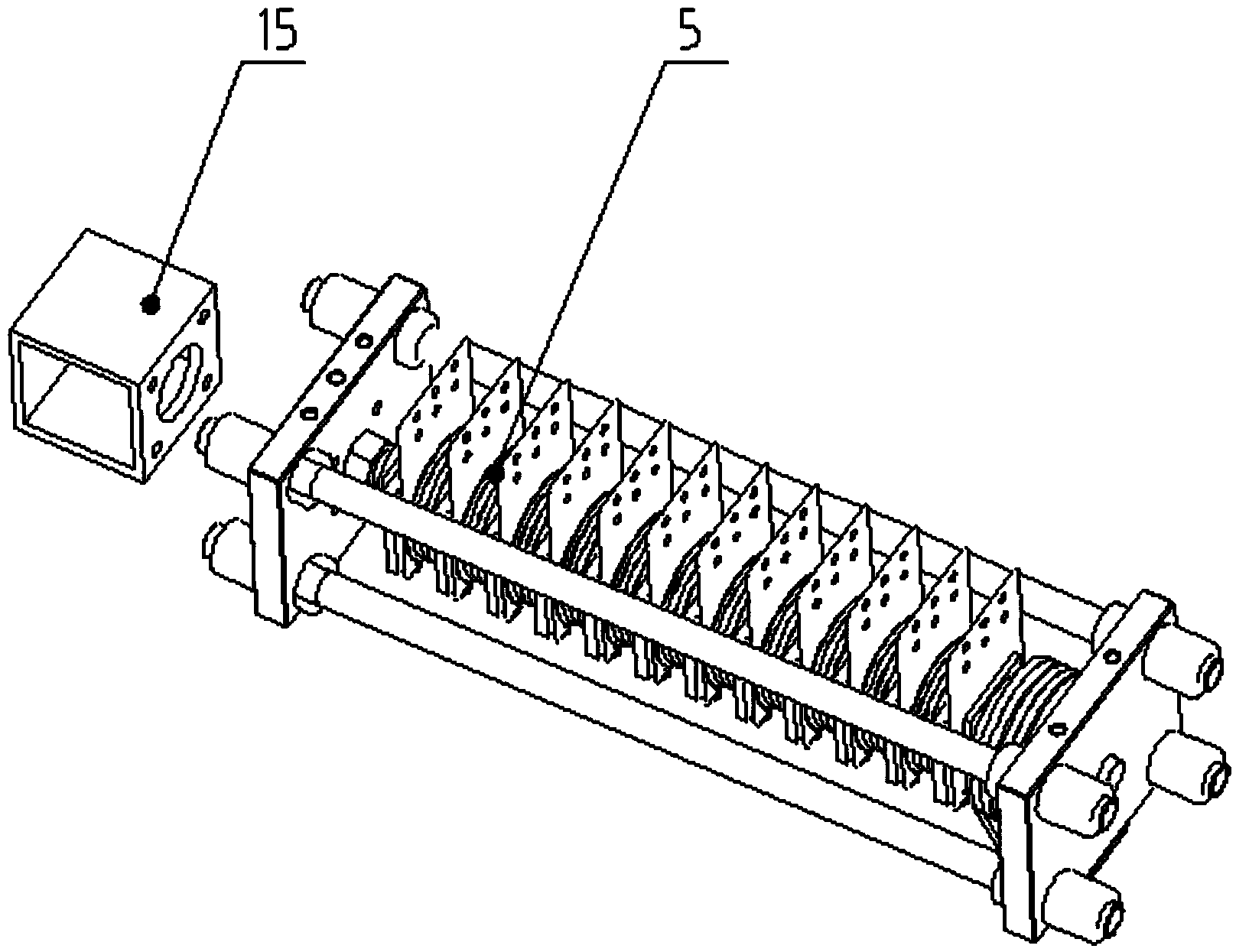

[0015] Such as Figure 1-3 As shown, a horizontal straight-mounted thyristor valve group, the thyristor valve group is formed by stacking three layers of single-layer valve groups, and the single-layer valve group 9 includes a shield cover 1, a supporting structure 2, a beam 3 and silicon Stack 5, the shielding cover 1, supporting structure 2 and crossbeam 3 form a frame, and the silicon stack 5 is placed horizontally and fixedly on the crossbeam 3, and the interlayer water pipe 6, water resistance 7 and Capacitor 8, the interlayer water pipes 6 are connected through the main water pipe 10, the lower part of the interlayer water pipe 6 is connected to the bottom elbow 14; the single-layer valve group 9 is fixedly connected together through the interlayer insulator 11 , the number of interlayer insulators 11 between the single-layer valve groups 9 is 6, and the bottom single-layer valve group 9 is fixed on the ground through the bottom insulator 12 and the base 13 .

[0016] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com