Jute carpet and production method thereof

A production method and technology of jute, applied in carpets, chemical instruments and methods, layered products, etc., can solve the problems of low adhesion of plush, easy falling of plush, easy accumulation of dust, etc. The effect of not easily accumulating dust and not easily coming off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

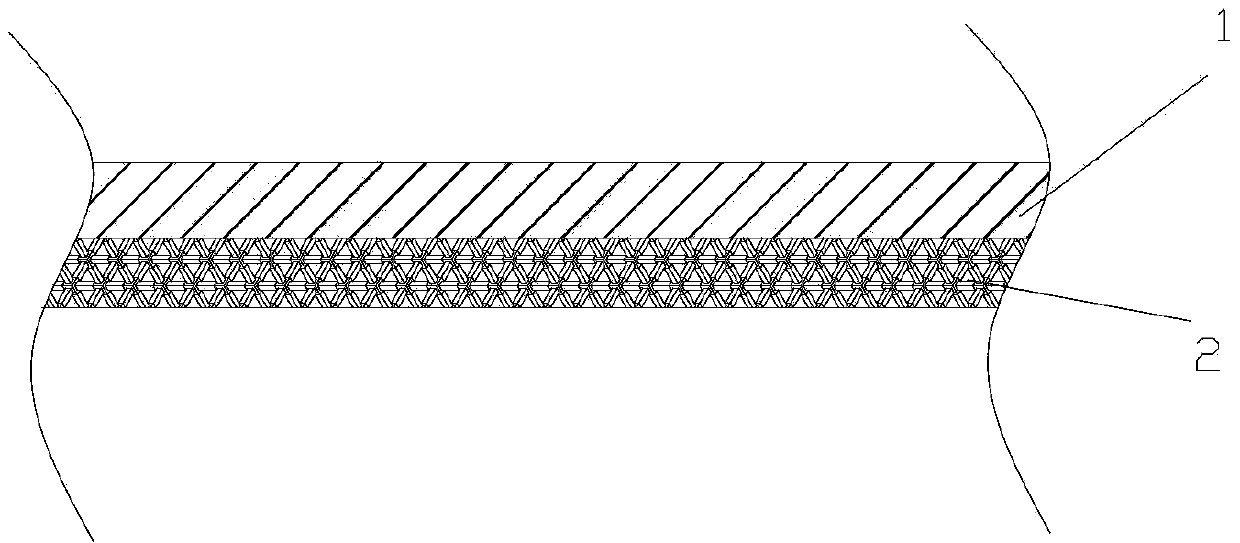

[0027] Such as figure 1 As shown, the jute carpet described in this embodiment includes a surface layer 1 and a bottom layer 2, the surface layer 1 is a jute woven layer, and the bottom layer 2 is a wood pulp spunlace nonwoven fabric.

[0028] The jute carpet described in this embodiment, the surface layer 1 is a jute weaving layer, and the jute weaving layer has a middle cavity structure, which has a good sound-absorbing effect. Compared with those carpets with rich texture and surface piles, it is not easy to accumulate Dust will not cause lint, and the jute cloth is cheap, which reduces the cost of making carpets. The bottom layer 2 is a wood pulp spunlace non-woven fabric, which has excellent dust-free, soft and antistatic properties, and can directly contact the floor without damaging the surface of the floor, and also has strong durability. Therefore, the obtained jute carpet has good sound-absorbing effect, is not easy to accumulate dust and damage the floor, and has g...

Embodiment 2

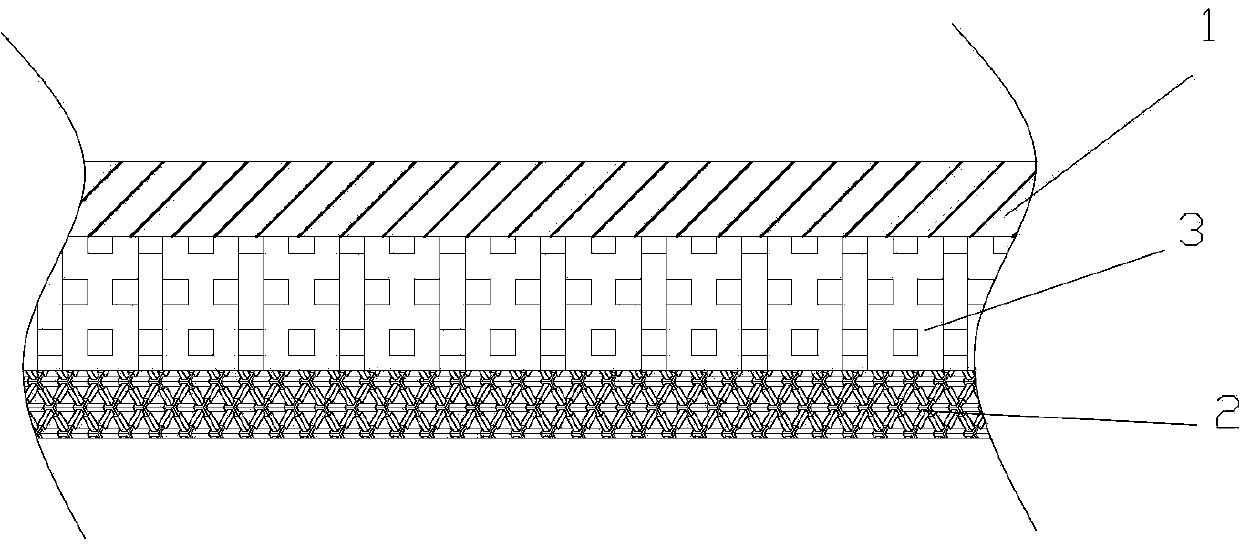

[0030] Such as figure 2 Said, the jute carpet described in this embodiment is different from Embodiment 1 in that: a sponge layer 3 is also provided between the surface layer 1 and the bottom layer 2, and the sponge layer 3 is a memory foam layer 3, and the sponge layer Layer 3 has a thickness of 1 cm. Such a setting can be softer and more comfortable when people walk on it.

[0031] Obviously, the above-mentioned embodiment can also have a corresponding simple modification: the thickness of the sponge layer 3 can be changed arbitrarily between 1 cm and 1.5 cm.

Embodiment 3

[0033] The production method of jute carpet described in the present embodiment is characterized in that comprising the steps:

[0034] A, the weaving step of jute weaving layer;

[0035] B. The step of spraying glue on the jute weaving layer;

[0036] C, the step of laminating the wood pulp spunlace non-woven fabric on the jute weaving layer that has been sprayed with glue;

[0037] D, the step of compressing the wood pulp spunlace non-woven fabric and the jute weaving layer through the pressure roller for the first time;

[0038] E, the steps of drying and conveying;

[0039] F, the step that the wood pulp spunlace non-woven fabric and the jute braided layer are pressed for the second time by pressing rollers;

[0040] G, the step of cutting the bonded wood pulp spunlace non-woven fabric and jute weaving layer into carpet;

[0041] H, the steps of wrapping.

[0042] Adopt the production method of jute carpet designed by the present invention, can produce the good jute c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com