Single-tower double-loop limestone-gypsum wet-method desulfuration device and method

A wet desulfurization, double-loop technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as changing the desulfurization operation mode of the absorption tower, and achieve the reduction of system operating costs, good dual-use, and prevention of wall damage. The effect of the flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

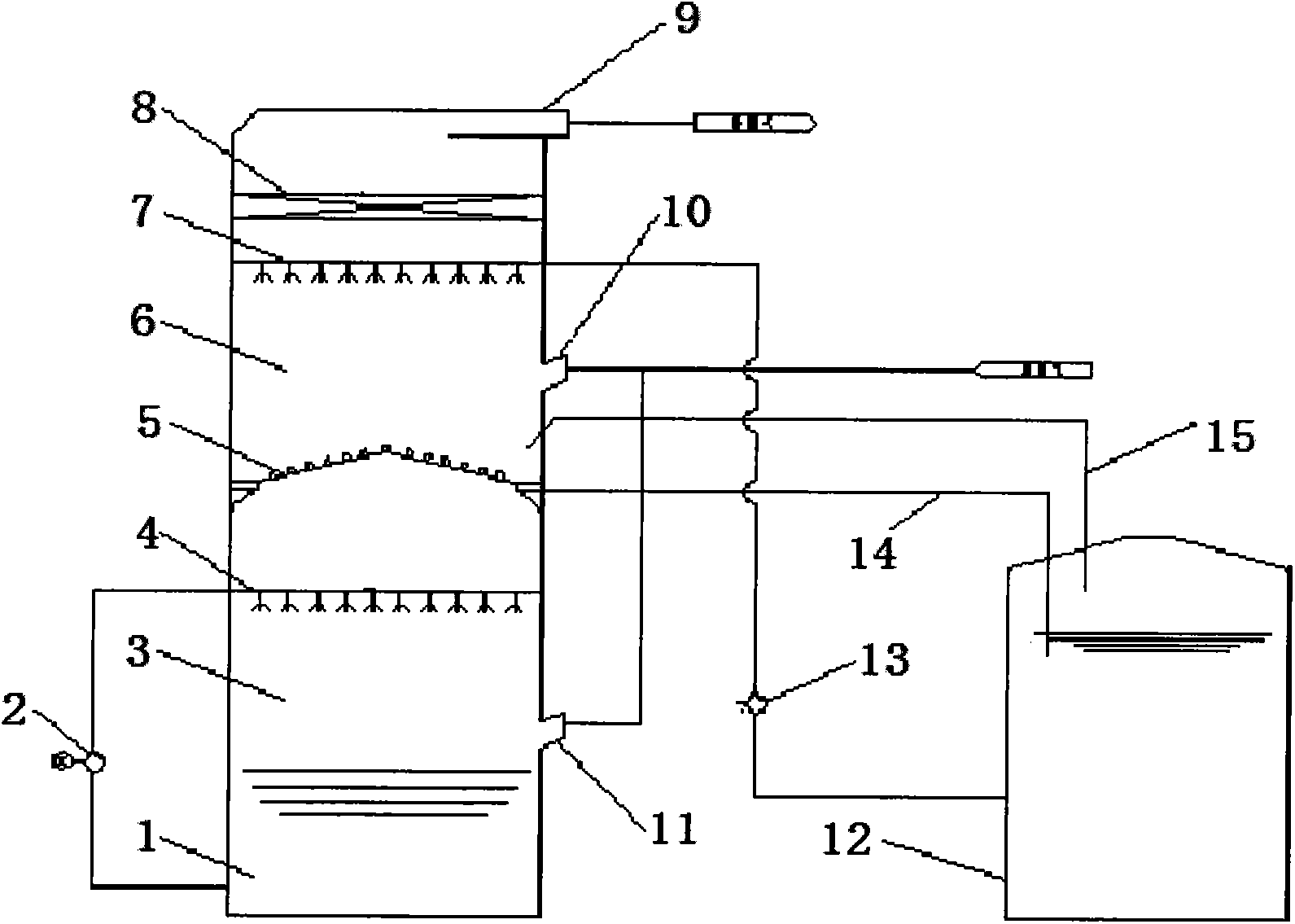

[0039] Example 1 Single tower double loop limestone-gypsum wet desulfurization device

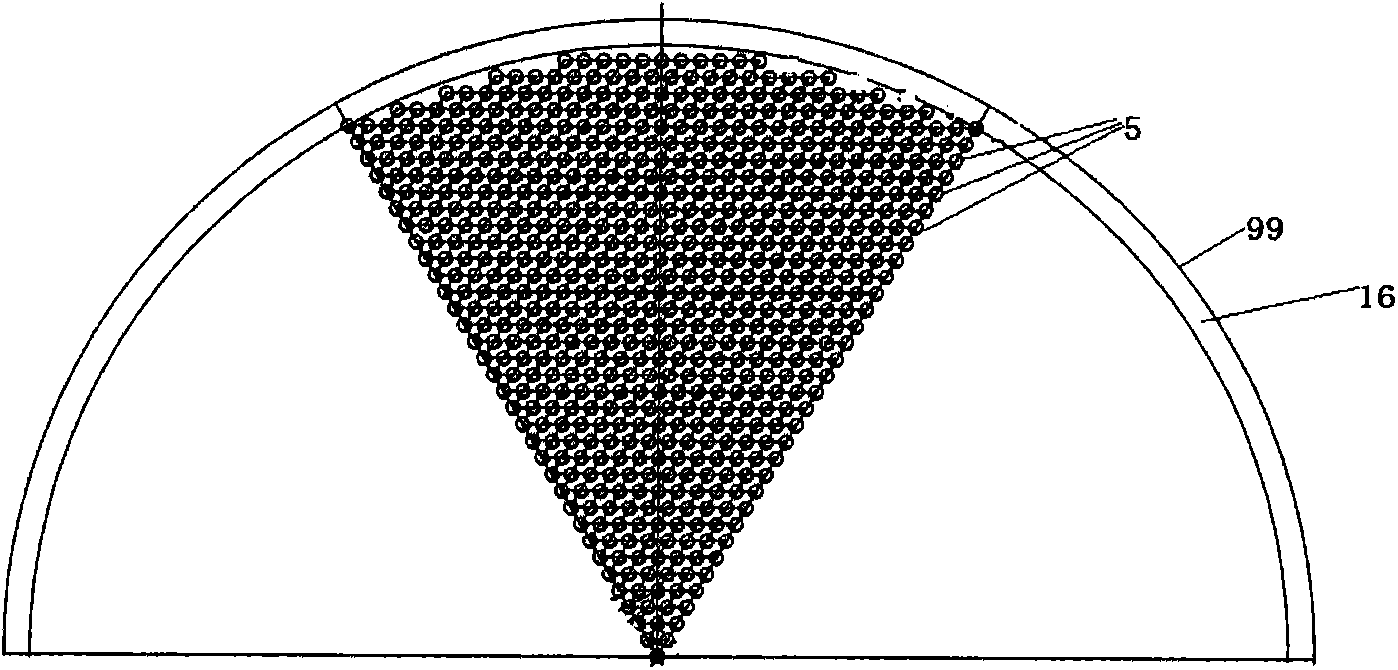

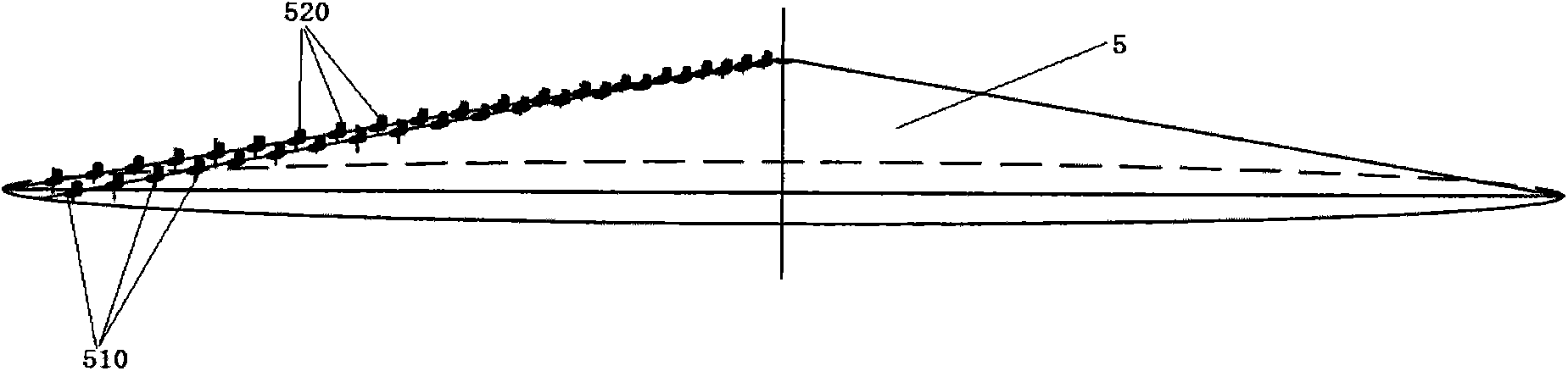

[0040] According to the attached figure 1 In the single-tower double-loop limestone-gypsum wet desulfurization device of the present invention shown, the first-level spray system 3, the double-loop baffle 5, the second-level spray system 6 and the absorption tower outlet 9 are in the absorption tower Set in order from bottom to top. The first-level spray system 3 includes a slurry oxidation tank 1, a lower circulation spray layer 4 and a lower circulation absorption tower inlet 11. The slurry oxidation tank 1, a lower circulation absorption tower inlet 11 and a lower circulation spray layer 4 are arranged from bottom to top At the lower part of the absorption tower, the slurry oxidation tank 1 and the lower circulating spray layer 4 are connected by a lower circulating slurry circulating pump 2. The secondary spray system 6 includes the upper circulation spray layer 7, the upper circulation a...

Embodiment 2

[0041] Example 2 Single tower double loop limestone-gypsum wet desulfurization method

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com