Moss cleaner

A cleaning machine and moss technology, applied in the field of moss cleaning machines, can solve the problems of time-consuming and laborious manual removal, no mud scraper in the pool, and high cost of chemical removal, achieving fast cleaning speed, easy to grasp or change, and easy to continue cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

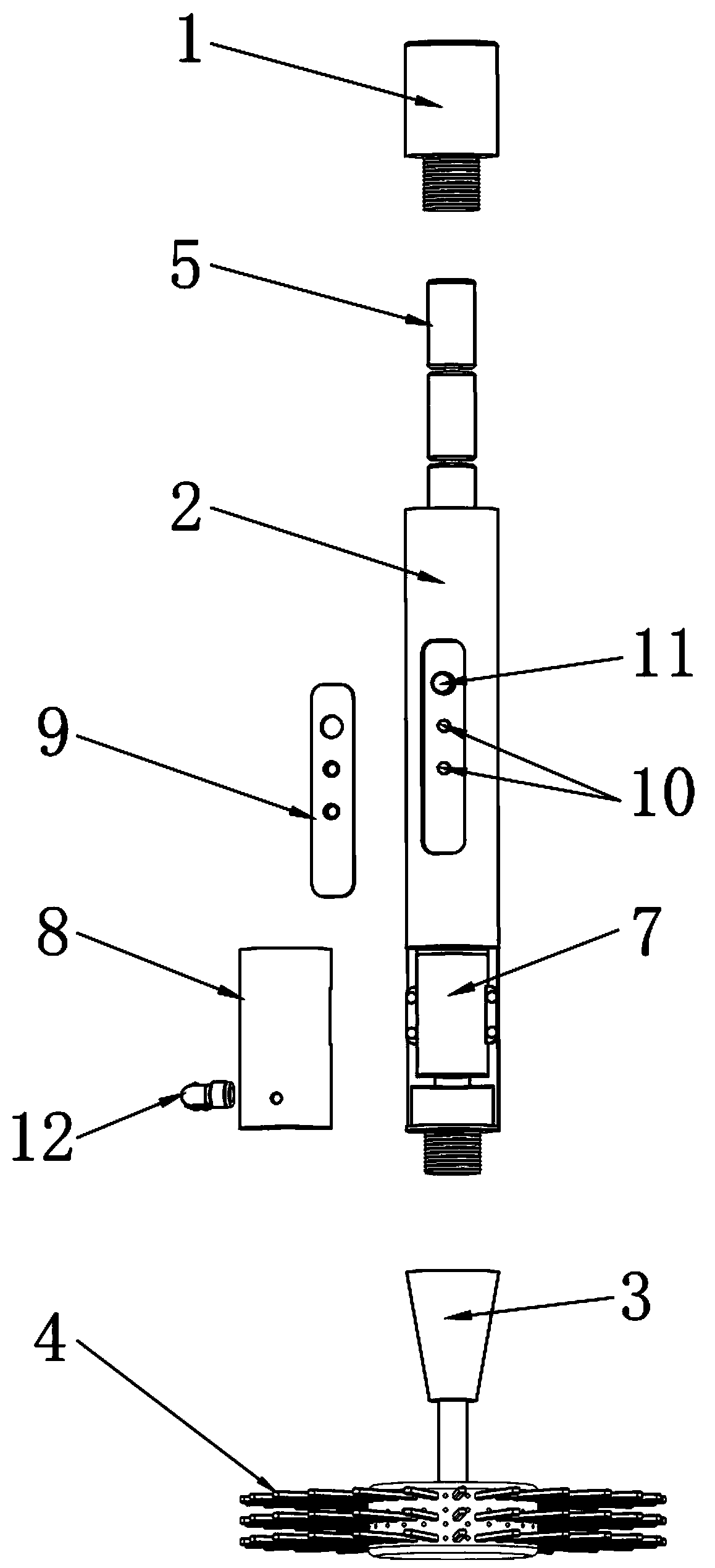

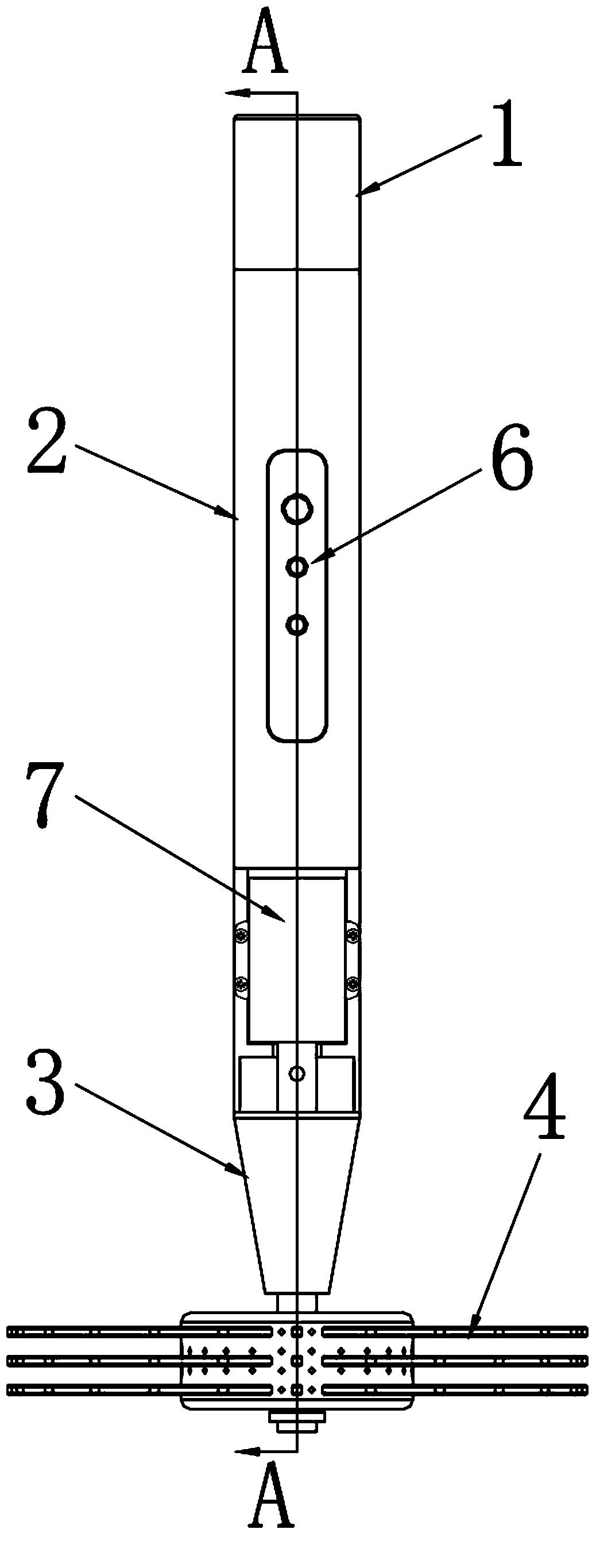

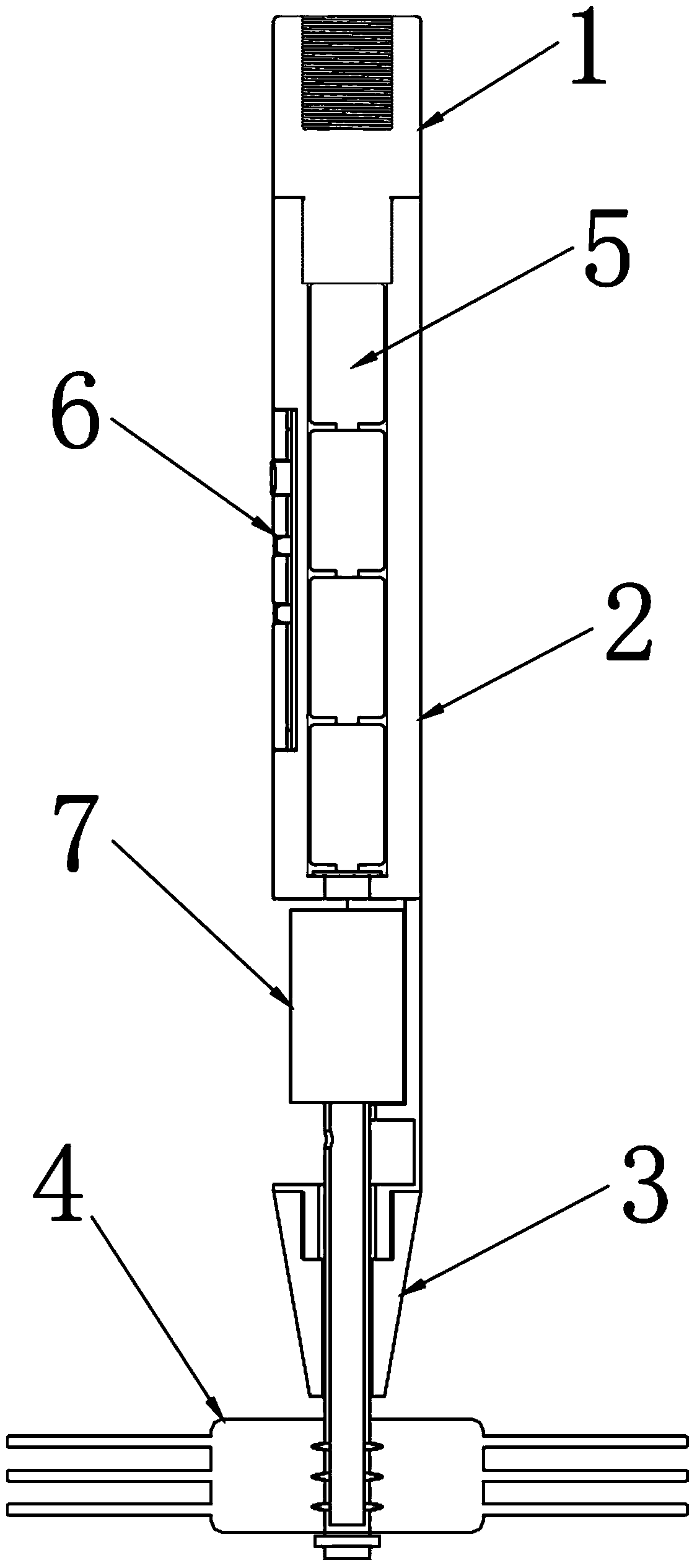

[0028] Such as figure 1 Shown, a kind of moss cleaning machine of the present invention is used for removing the moss that grows on sewage treatment equipment, and the present invention comprises: fuselage 2, cleaning element 4 and jet unit, and cleaning element 4 is connected with the front end of fuselage 2, and can Rotate around the length direction of the fuselage 2; the fuselage 2 is connected with the cleaning element 4 through the motor 7 arranged at its front; the front of the fuselage 2 is provided with a motor compartment, the rear of the motor compartment is the motor 7, and the front is for ventilation warehouse. The fuselage 2 is also provided with several b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com