Automatic on-off pressure device of offset press

An automatic clutch and offset printing machine technology, applied to printing machines, rotary printing machines, printing, etc., can solve the problems of high labor intensity, accumulated processing errors, large assembly errors, and high costs, and achieve short printing auxiliary time and reduce labor intensity , machine performance and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

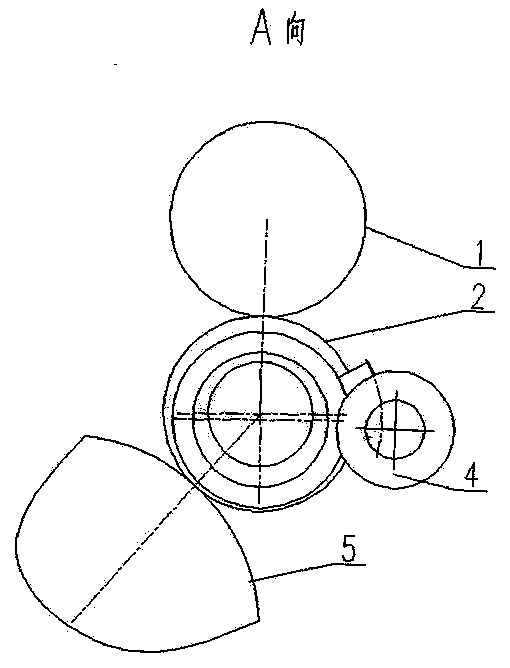

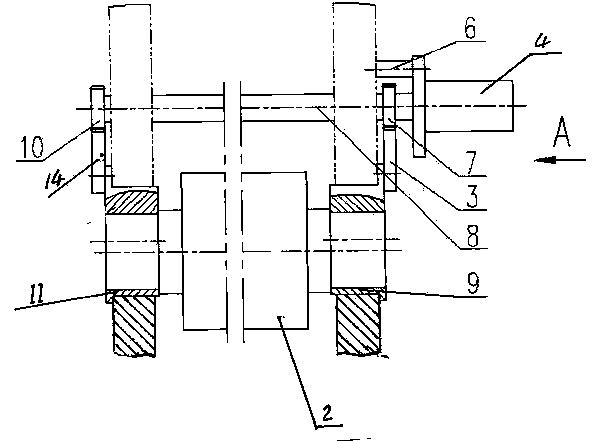

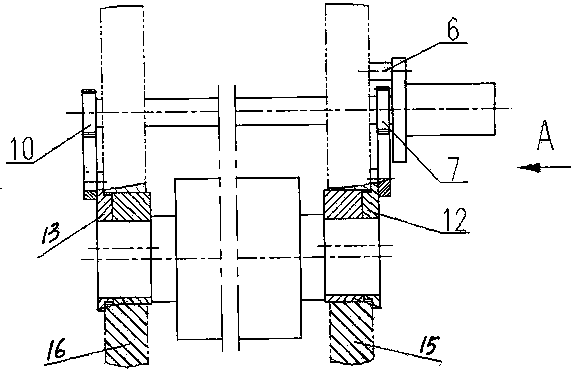

[0011] Such as figure 1 , figure 2 Shown, between the left and right wallboards 16,15 and between the wallboards, an impression cylinder 5, a rubber cylinder 2, a printing plate cylinder 1 and a clutch pinch 8 are installed, and a driver 4 is installed at one end of the clutch pinch, and the driver 4 passes through the Axis 6 is fixed on the left and right wallboards. Further: the driver 4 can be selected from servo motor, stepping motor and rotary motor, etc. Taking the servo motor as an example, the motor shaft on the servo motor can be connected with the clutch final shaft through a key, and the rubber The two ends of the drum 2 are equipped with left and right eccentric sleeves 11, 9 symmetrically on the axial heads, and the left and right eccentric sleeves are equipped with left and right tooth blocks 14, 3, and the left and right tooth blocks 14, 3 It is fixedly connected with the left and right eccentric sleeves by screws, and the left and right tooth blocks are equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com