A device and method for measuring and monitoring the inclination angle of a pantograph carbon sliding plate

A pantograph carbon slide and monitoring device technology, which is applied to current collectors, electric vehicles, power collectors, etc., can solve problems such as shortened service life, carbon slide wear through, and easily damaged pantographs, so as to prevent railway accidents , prolong service life and save cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical scheme of the present invention will be further described in detail below in conjunction with the accompanying drawings:

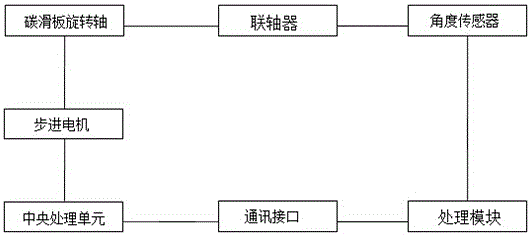

[0027] The invention discloses a measuring and monitoring device for the inclination angle of a pantograph carbon sliding plate, such as figure 1 As shown, it includes pantograph, carbon slide, and also includes coupling, angle sensor, processing module, communication interface, central processing unit, stepping motor, steel wire rope and carbon slide rotation axis,

[0028] The carbon slide plate is connected to the pantograph through a coupling, the coupling includes a driving shaft and a driven shaft, and the angle sensor is connected to the driving shaft of the coupling;

[0029] The data output terminal of the angle sensor is connected with the data input terminal of the processing module, and the data output terminal of the processing module is connected with the data input of the central processing unit through a communication interfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com