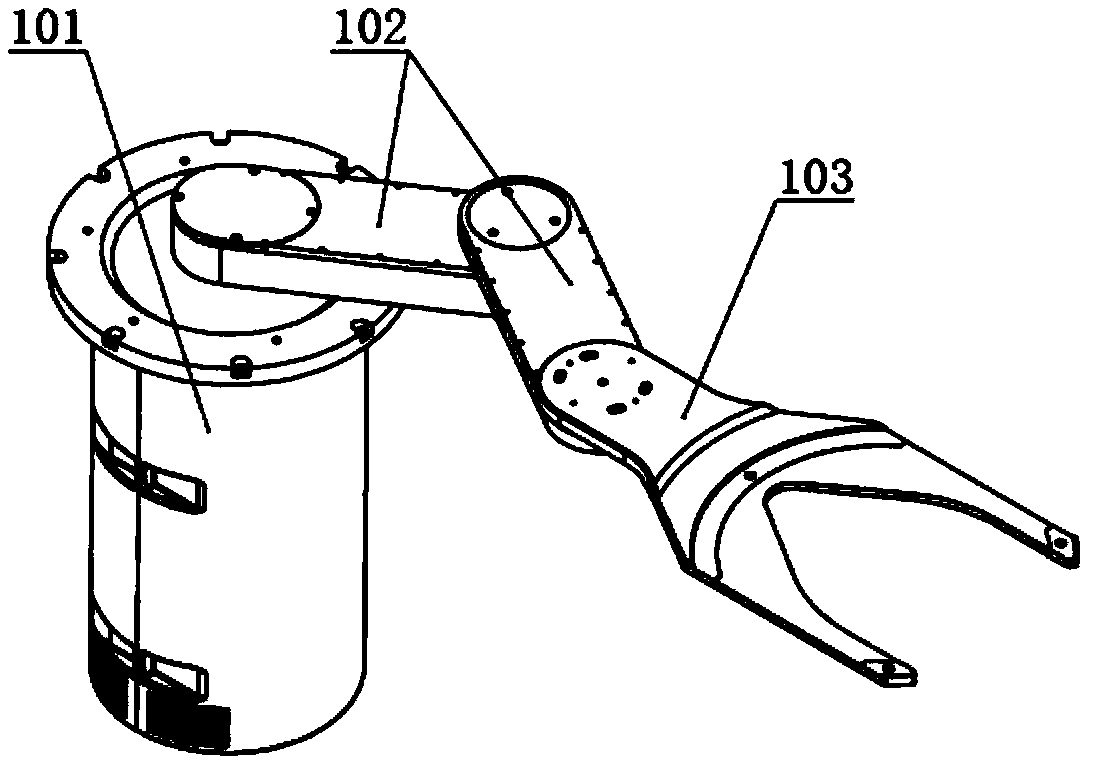

Transmitting device and plasma machining equipment

A transmission device and processing technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of short transmission distance of the mechanical arm, unable to meet the transmission distance requirements, etc., and achieve the effect of simple structure, easy control and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order for those skilled in the art to better understand the technical solution of the present invention, the transmission device and the plasma processing equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

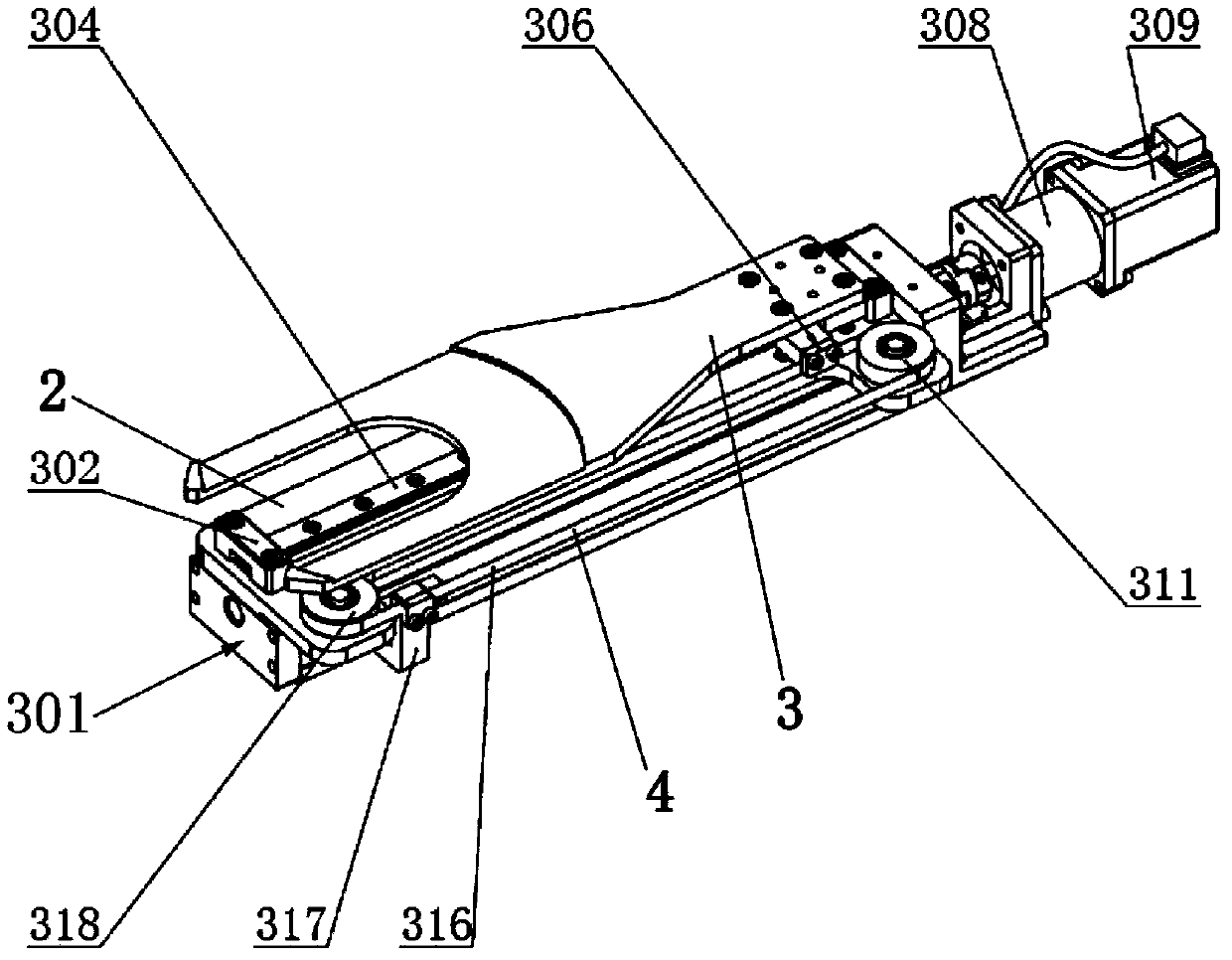

[0035] image 3 It is a perspective view of the transmission device provided by the first embodiment of the present invention. Figure 4 It is a cross-sectional view of the transmission device provided by the first embodiment of the present invention. Please also refer to image 3 with Figure 4 , the transmission device includes a linear drive unit, a fixed part 2, a gripping part 3 and an indirect transmission mechanism 4. Wherein, the linear drive unit is used to drive the fixed component 2 to perform linear reciprocating motion. In this embodiment, the linear drive unit includes a housing 301 , a rotating motor 309 , a lead screw 11 and a second sliding member 12 . Wherein, the lead s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com