Tracking and positioning system of ground chain conveying chain

A tracking and positioning, conveyor chain technology, applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of tracking locator damage, fixture vertical, dimensional errors, etc., to achieve smooth and accurate movement, tracking The locator is stable and ensures the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

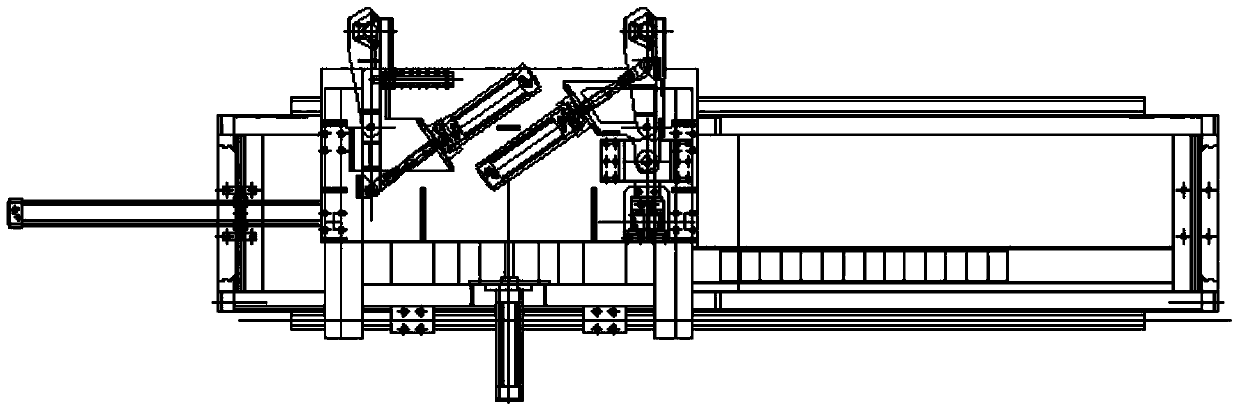

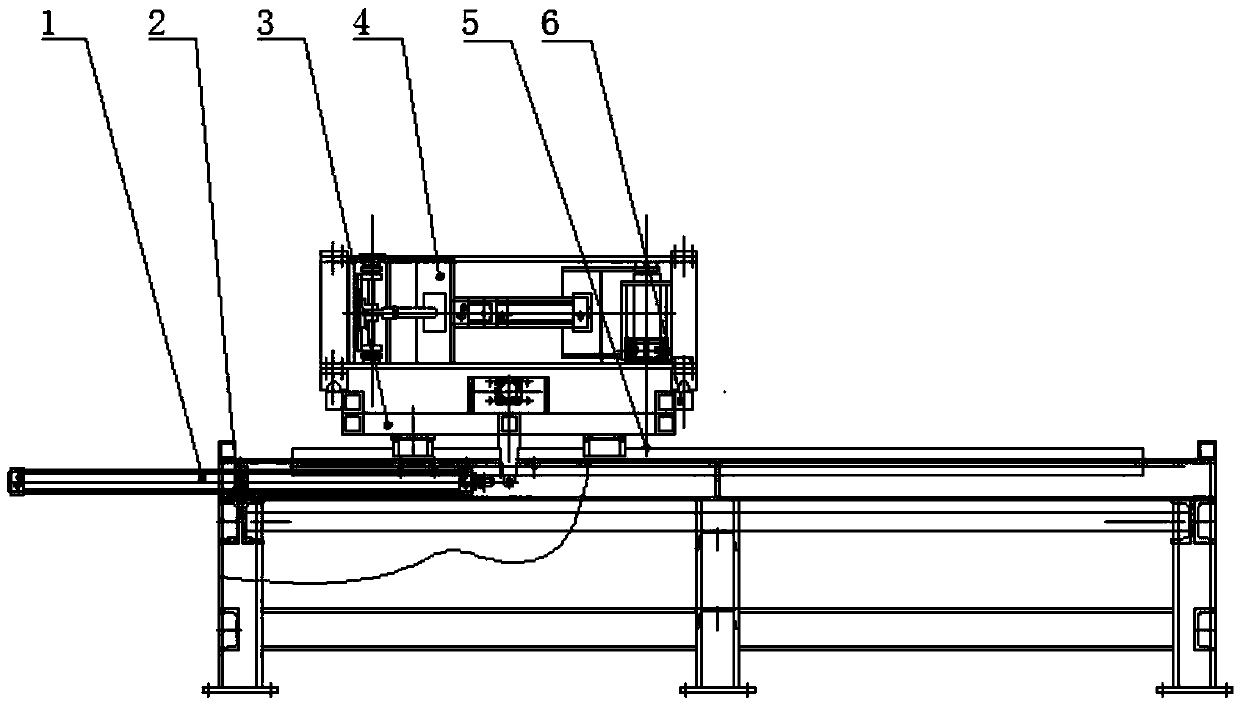

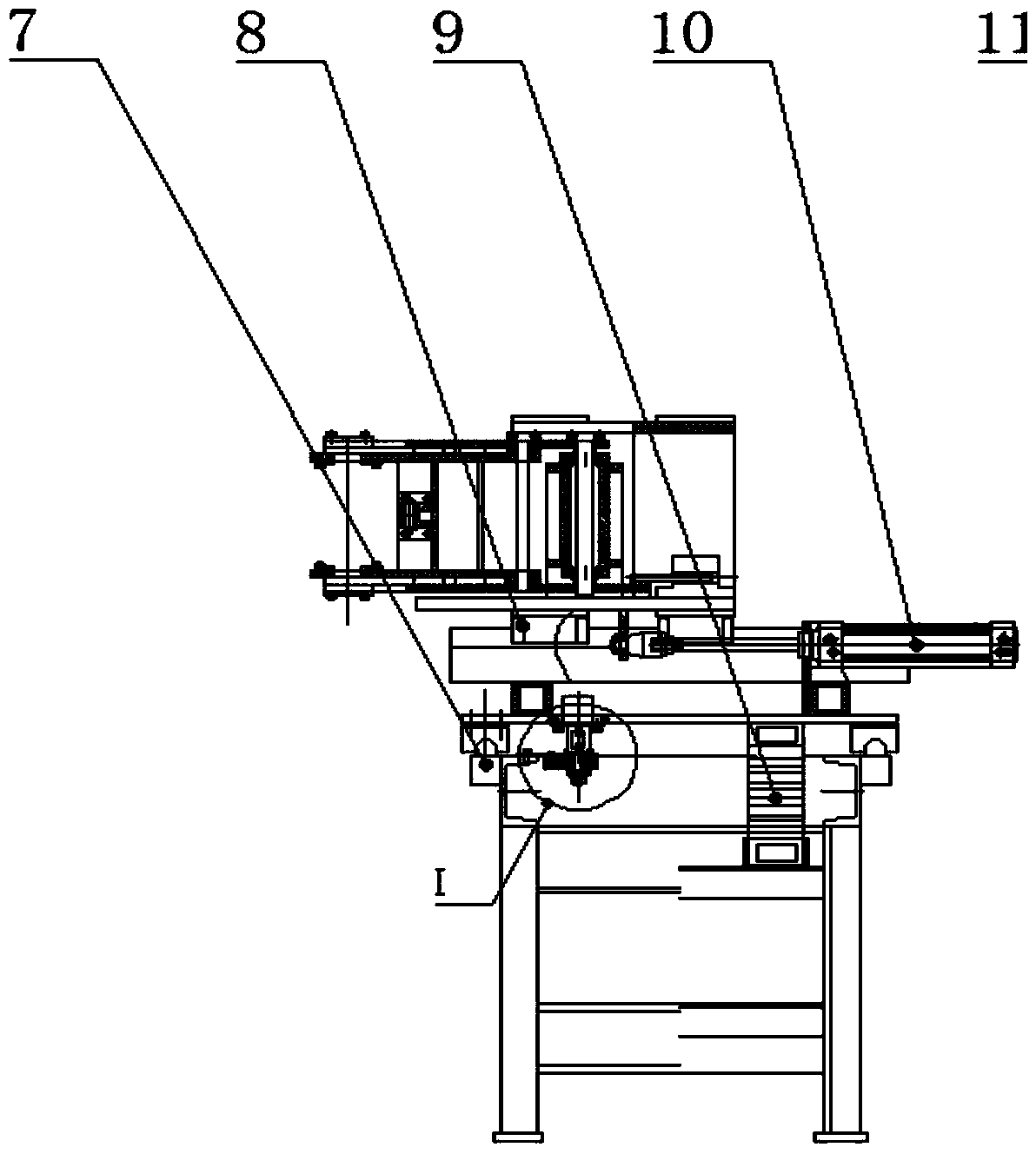

[0023] The embodiment of the present invention provides a ground chain conveyor chain tracking and positioning system, which is used to transport workpieces that are placed on a jig, which includes a positioning mechanism, a robot gripper mechanism, a ground chain conveying system, and a control mechanism. The positioning mechanism and the robotic gripper mechanism are respectively connected to the control mechanism, and the robotic gripper mechanism is connected to the ground chain conveying system;

[0024] The following positioning mechanism and the robot hand grip are respectively set at two different initial positions. When the positioning mechanism detects a fixture, the control mechanism controls the positioning mechanism to position the fixture so that Maintaining a fixed posture, the robot gripper mechanism grabs the workpiece on the fixture, and the robot gripper mechanism transfers the workpiece to a fixture on another conveyor line under the control of the control mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com