Bar material blank processing device

A blank processing and bar technology is applied in the field of bar blank processing devices, which can solve the problems of consuming diamond grinding wheels, large grinding waste, and low product qualification rate, so as to improve processing efficiency, reduce pre-burning links, and solve inconvenient installation. clip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

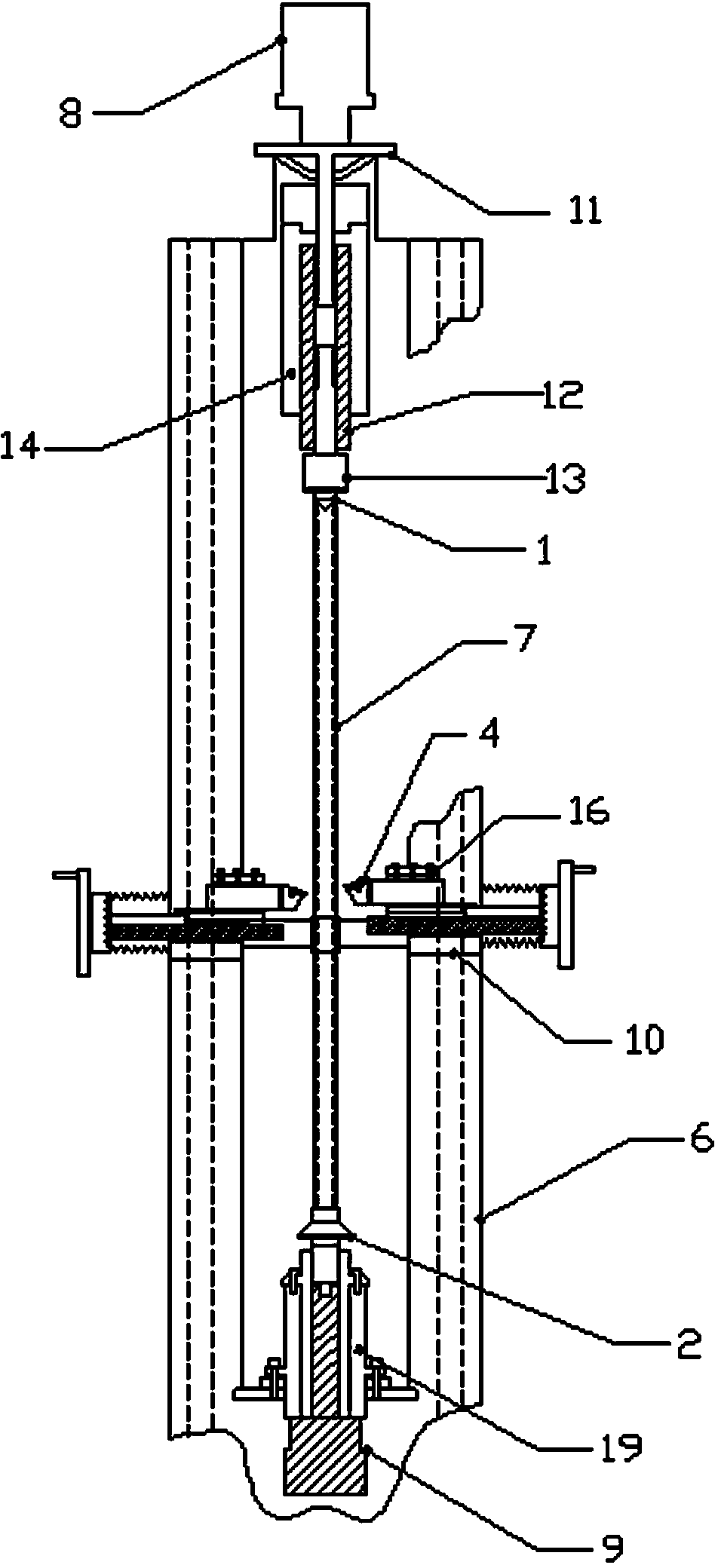

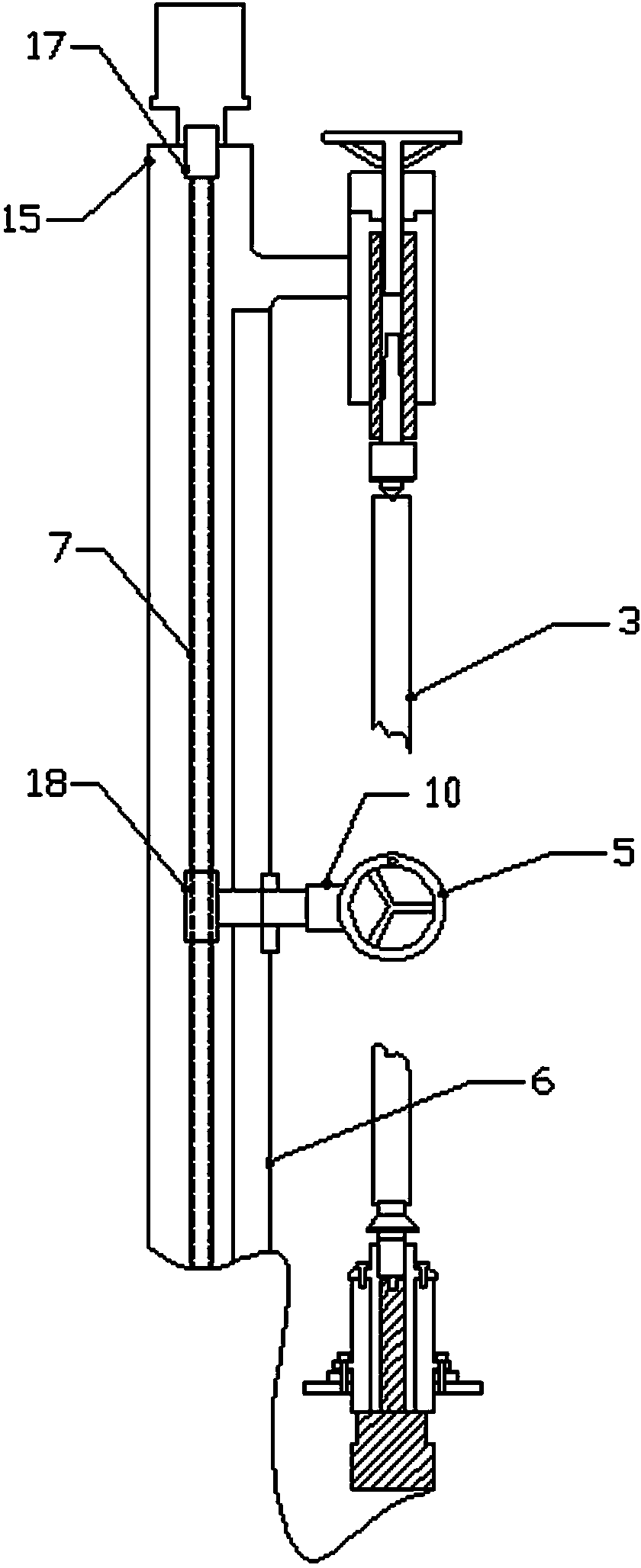

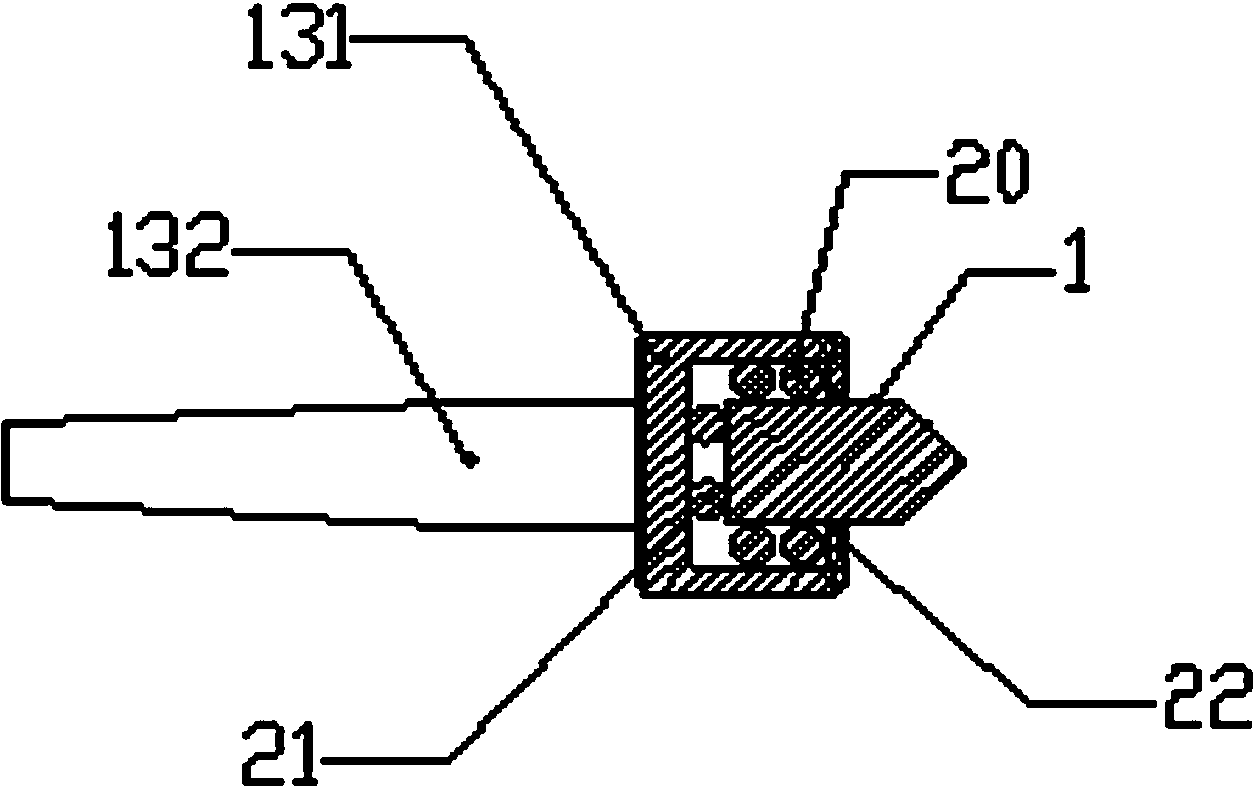

[0021] Such as Figure 1 to Figure 4 As shown, the bar processing device disclosed in the present invention includes an upper thimble 1, a lower thimble 2, an outer circle turning tool 4, a transverse feed device 5, a linear ball guide 6, a ball screw 7, an upper servo motor 8, Lower servo motor 9, knife rest seat 10, clamping wheel 11, bushing 12, thimble seat 13, base 14, column 15, knife rest 16, coupling 17, nut seat 18, fastening fixture 19, bearing 20 .

[0022] The upper thimble 1 and the lower thimble 2 are used to center the upper and lower ends of the bar blank 3. The outer circle turning tool 4 is fixed on the front end of the tool holder 16, and the tool holder 16 is fixed on the tool holder seat 10. Connected with a transverse feed device 5, the transverse feed device 5 is transversely connected on the knife rest seat 10, and its structure is the same as that of the prior art. The linear ball guide rail 6 is fixed on the column 15, the ball screw 7 is arranged p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com