Device and method for detecting hydrogen evolution performance at different parts of supported catalyst

A supported catalyst and detection device technology, which is applied in the field of electrocatalytic hydrogen evolution, can solve the problems of the utilization rate not reaching the maximum performance, the scarcity of precious metal energy, and the lack of detection methods, etc., to solve the problem of difficult control of clamping precision and solve the problems of clamping Inconvenience, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

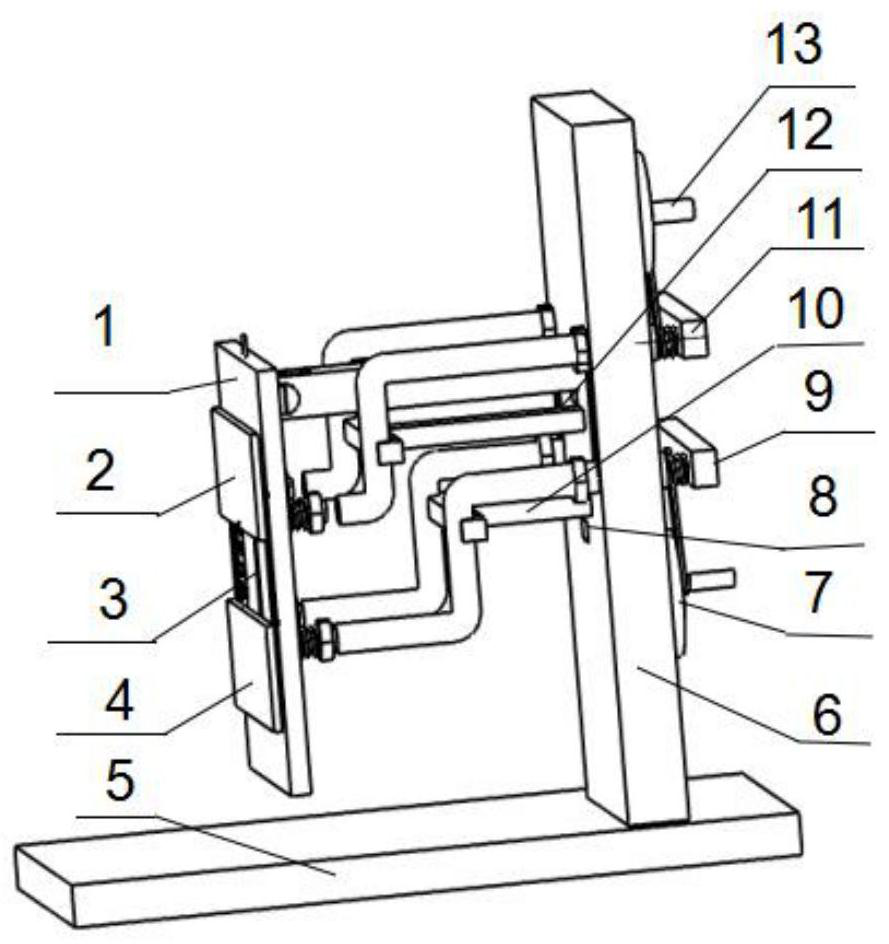

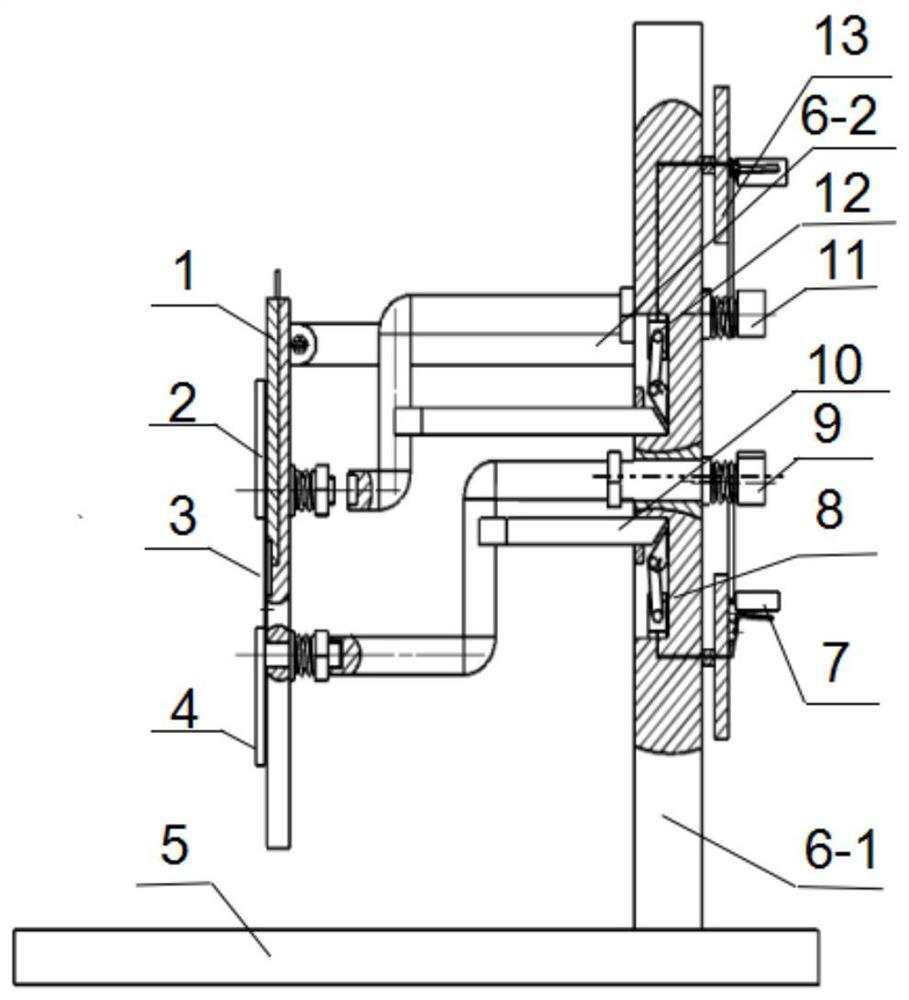

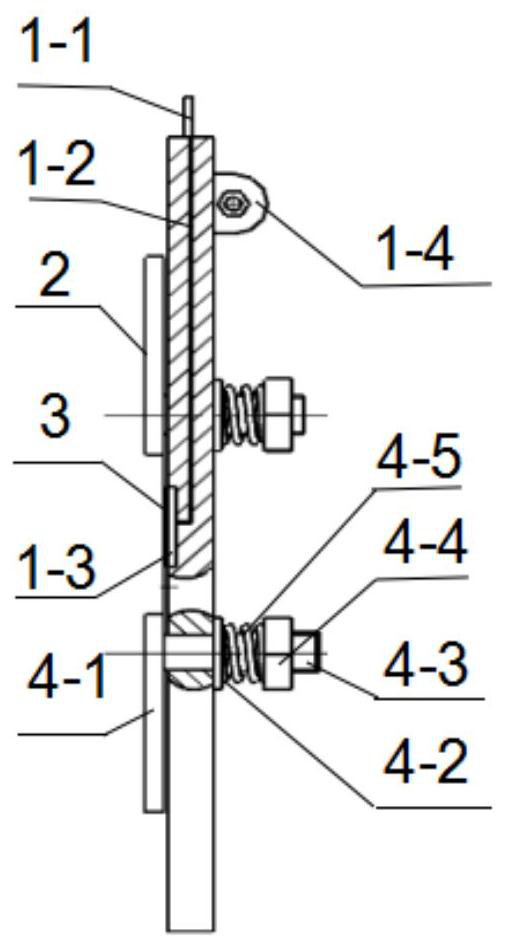

[0049] The CoP / NF catalyst is divided into n=5, L=1cm, B=0.2cm, and the five parts are marked as 1#, 2#, 3#, 4#, 5# from top to bottom. Put the CoP / NF on the electrode plate 1 where the upper edge of the catalyst is flush with the 0 scale line of the first scale line 1-5, then press the L-shaped rod 7-2 to move the connecting belt 8-7, thereby pulling The slide block 8-5 moves downwards, and then pulls the propulsion wheel 8-1 to rotate through the connecting rod 8-3, thereby pushing the T-shaped guide block 10 to move to the left, and the reciprocating column 9-6 moves to the left together, and the reciprocating column 9-6 Then push the connecting column 4-3, the pressure plate 4-1 moves to the left, separate from the CoP / NF; rotate together with the pressed L-shaped rod 7-2 and the rocker 7-6, and push the connecting plate through the connecting rod 7-7 9-1. The reciprocating column 9-6 moves upward, pushes the pressure plate 4-1 to move upward to the scale line 0.2 through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com