New energy automobile equipotential test system and test method

A new energy vehicle and test system technology, applied in the field of electric vehicle testing, can solve the problems of testers confusing the measured points, difficult on-site management, poor data comparability, etc., and achieve the effect of flexible and diverse test methods and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

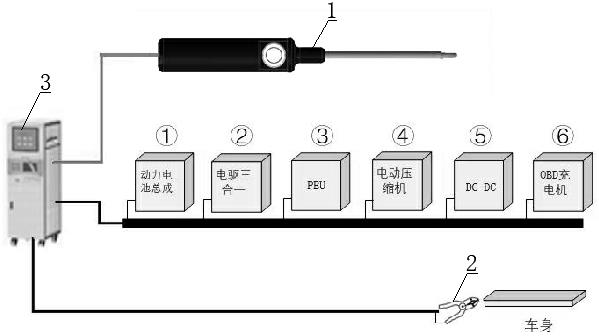

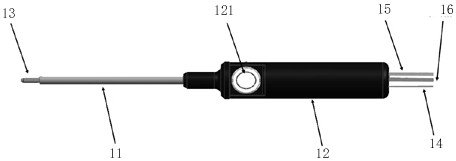

[0051] like Figure 1-4 As shown, an equipotential testing system for a new energy vehicle includes a detection probe 1 , a grounding chuck 2 and a control machine 3 .

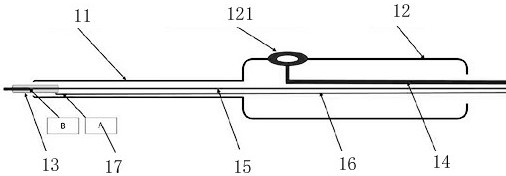

[0052] The detection probe 1 includes a probe rod 11 , a detection handle 12 , a moving contact B13 , a moving contact A17 , a signal control line 14 , a voltage signal input line 15 , and a test current output line 16 .

[0053] The probe rod 11 includes a copper core tube and an insulating protection sleeve, and the insulating protection sleeve is arranged on the outer periphery of the copper core tube.

[0054] The movable contact A17 and the movable contact B13 are metal conductors, the movable contact B13 is telescopically connected to the front end of the copper core tube, and the detection handle 12 is connected to the rear end of the probe rod 11 . The moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com