Preparation method of common auxiliary material

A technology of octadecyl alcohol ester and maleic acid mono, which is applied in the field of preparation of sodium stearyl fumarate as an auxiliary material for pharmaceutical preparations, and can solve the problems of increasing unsafe factors, high cost, and high reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

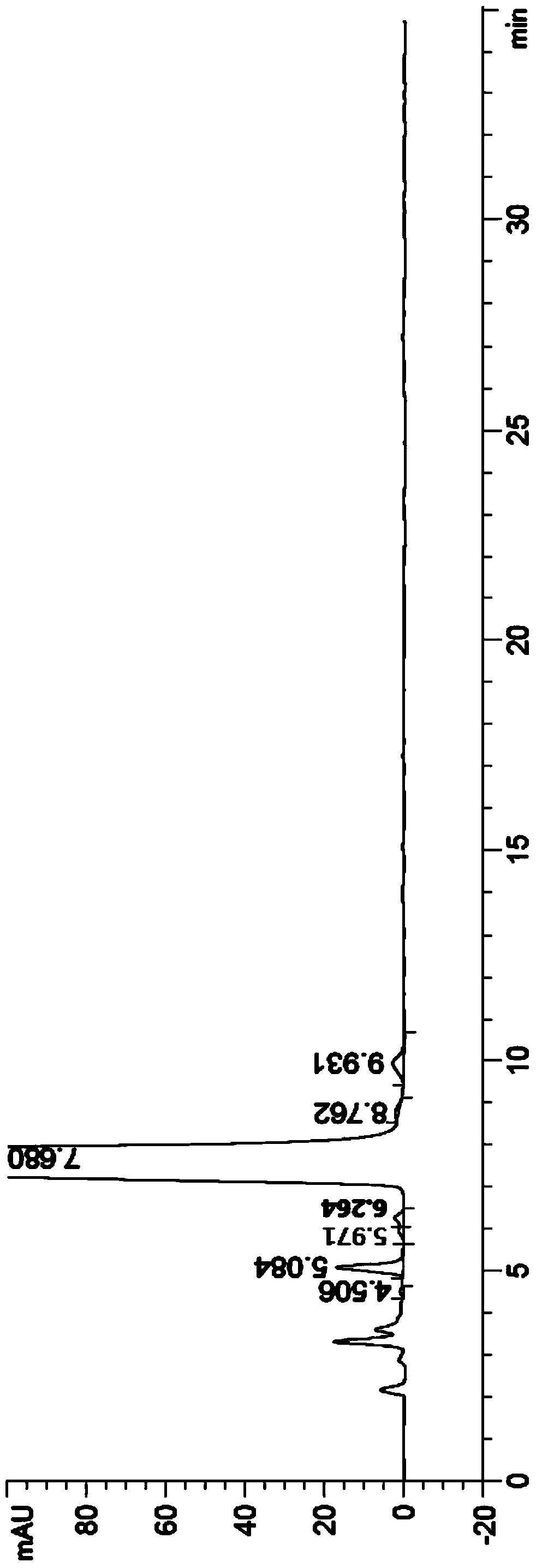

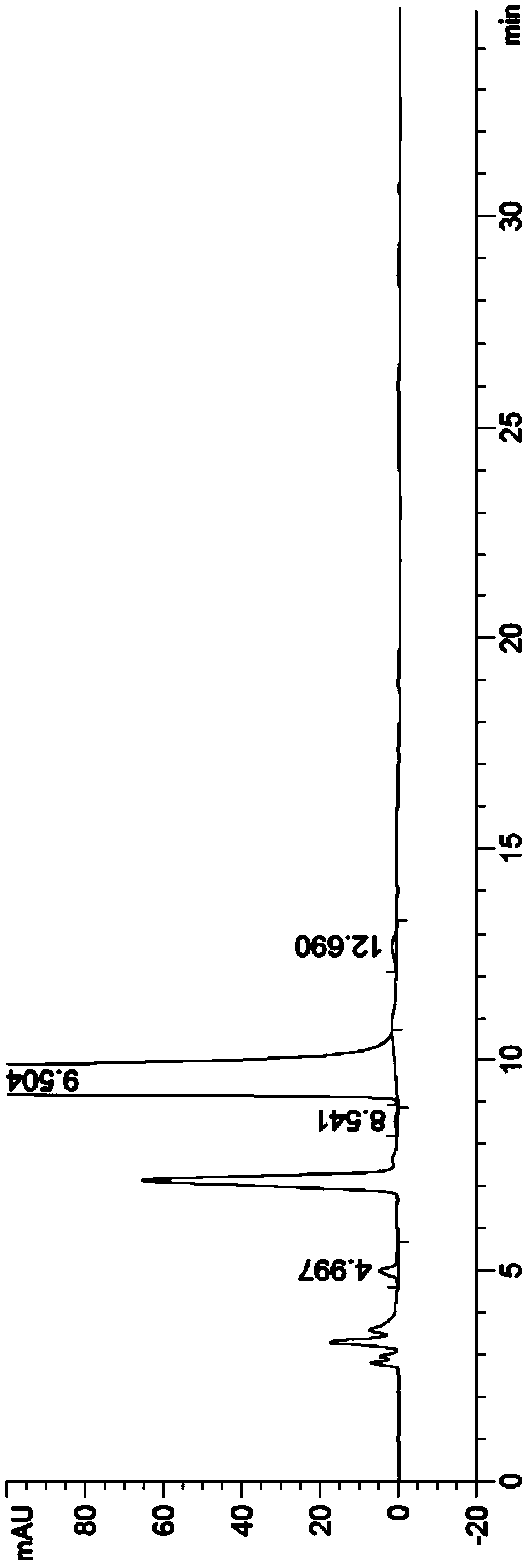

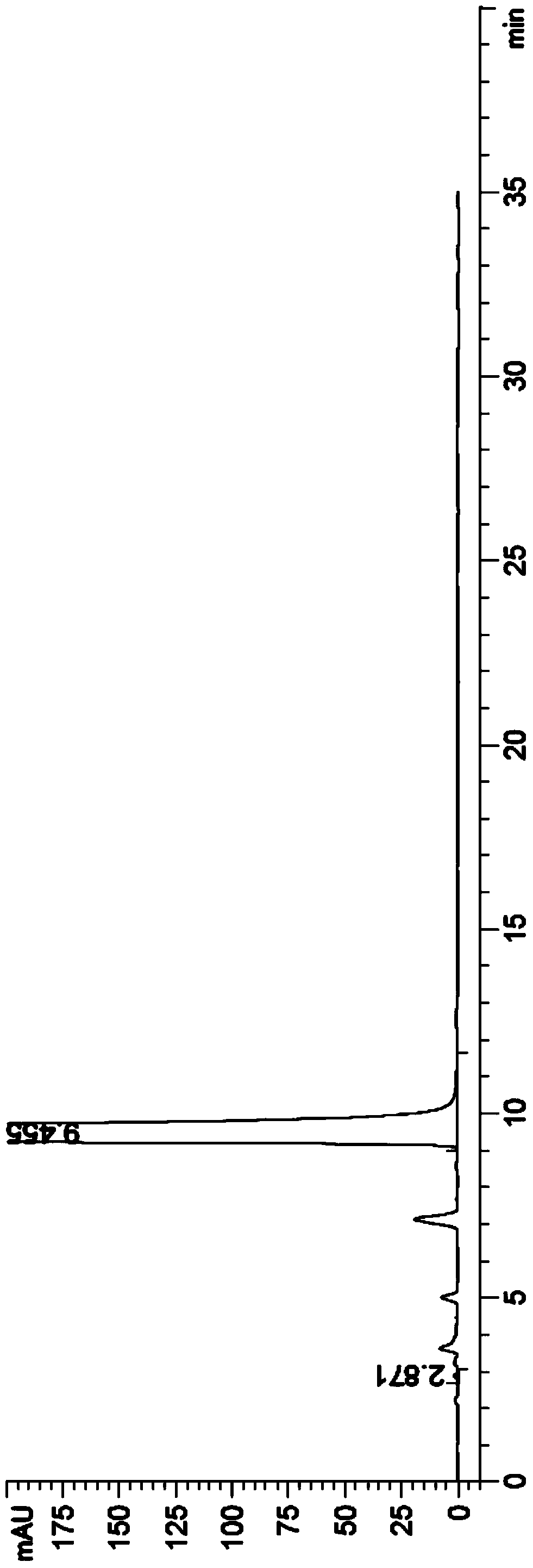

Image

Examples

Embodiment Construction

[0010] In a first aspect, the present invention provides a method for preparing the intermediate monostearyl maleate for the preparation of sodium stearyl fumarate.

[0011] A preparation method of monostearyl maleate, comprising: reacting stearyl alcohol and maleic anhydride in the presence of an organic basic catalyst to prepare monostearyl maleate.

[0012] By adding an organic basic catalyst, the reaction temperature can be lowered, and problems such as insecurity and high impurities caused by high-temperature reactions can be avoided. The organic basic catalyst is selected from one or more of triethylamine, diethylamine, diisopropylethylamine, pyridine, and ethylenediamine. In some embodiments, the organic basic catalyst is selected from triethylamine.

[0013] The amount of the organic basic catalyst is calculated according to the mass of stearyl alcohol, and the amount is 1%-10%; in some embodiments, the amount of the organic basic catalyst is 2%-4%; in some embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com