Wheat straw pulp elemental-chlorine-free bleaching wastewater recycling method

A technology for elemental chlorine and wheat straw pulp, which is applied in pulp bleaching and other directions to achieve the effects of reducing pollution load, saving clean water and reducing waste water production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The process wastewater reuse test was conducted using the following bleaching conditions:

[0016] Section D: pulp concentration 10%, Kappa factor 0.15, H 2 SO 4 2%, time 60min, temperature 60℃;

[0017] Q segment: pulp concentration 10%, EDTA 0.2%, H 2 SO 4 0.5%, time 60min, temperature 70℃;

[0018] P segment: pulp concentration 10%, H 2 o 2 2.0%, NaOH 1.0%, time 180min, temperature 90°C.

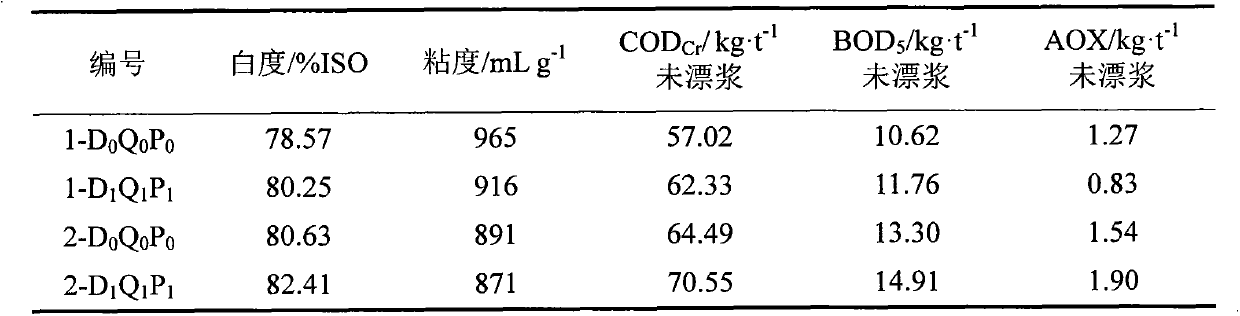

[0019] 1) 1-D 0 Q 0 P 0 bleach

[0020] D. 0 , Q 0 ,P 0 After each stage of bleaching, take the wastewater from the three stages of bleaching and mix them in proportion to detect the COD of the wastewater Cr 、BOD 5 , AOX, and detect P alone 0 Wastewater COD Cr 、BOD 5 , AOX; detection of pulp whiteness and viscosity after bleaching.

[0021] 2) 1-D 1 Q 1 P 1 bleach

[0022] D. 1 After bleaching, reuse P 0 The washing wastewater of bleached pulp to D 1 After stage bleaching, the pulp is concentrated to 1% pulp concentration. After the pulp is fully mixed ...

Embodiment 2

[0025] The process wastewater reuse test was conducted using the following bleaching conditions:

[0026] Section D: pulp concentration 10%, Kappa factor 0.20, H 2 SO 4 2%, time 60min, temperature 60℃;

[0027] Section Q: pulp concentration 10%, EDTA 0.2%, H 2 SO 4 0.5%, time 60min, temperature 70℃;

[0028] P segment: pulp concentration 10%, H 2 o 2 2.0%, NaOH 1.0%, time 180min, temperature 90°C.

[0029] 1) 2-D 0 Q 0 P 0 bleach

[0030] D. 0 , Q 0 ,P 0 After each stage of bleaching, take the wastewater from the three stages of bleaching and mix them in proportion to detect the COD of the wastewater Cr 、BOD 5 , AOX, and detect P alone 0 Wastewater COD Cr 、BOD 5 , AOX; detection of pulp whiteness and viscosity after bleaching.

[0031] 2) 2-D 1 Q 1 P 1 bleach

[0032] D. 1 After bleaching, reuse P 0 The washing wastewater of bleached pulp to D 1 After stage bleaching, the pulp is concentrated to 1.5% pulp concentration. After the pulp is fully mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com