Equipment for automatically and accurately repairing wavy abrasions to subway corner rail

A technology for corrugated rails, which is applied in the field of repairing corrugated rails in subway rails. It can solve the problems of large grinding and maintenance requirements, increased rail service life, and serious rail wear, and achieves light weight, reduced operating costs, and The effect of increasing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

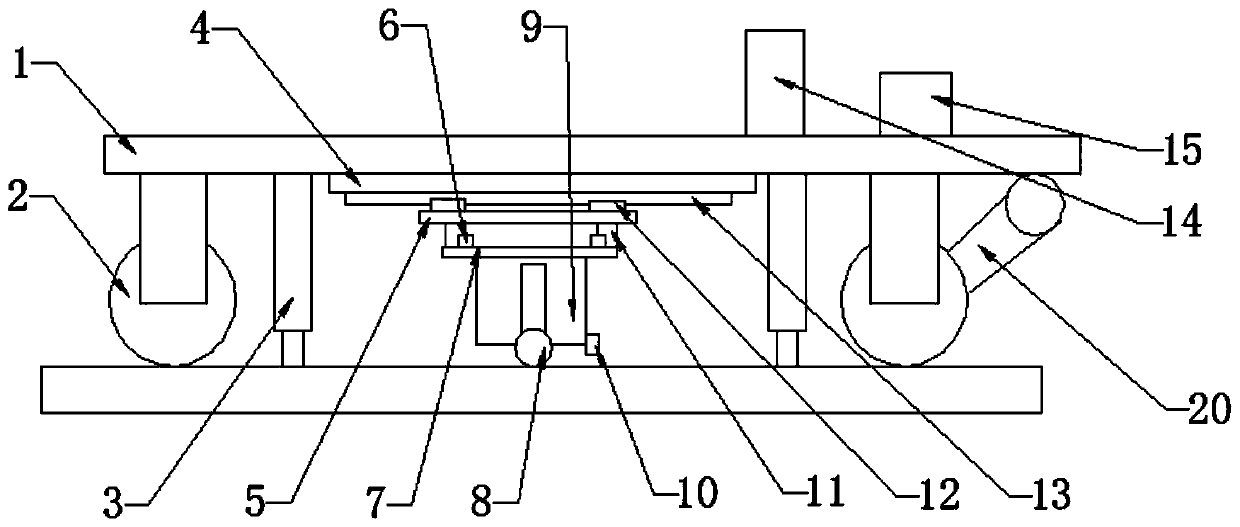

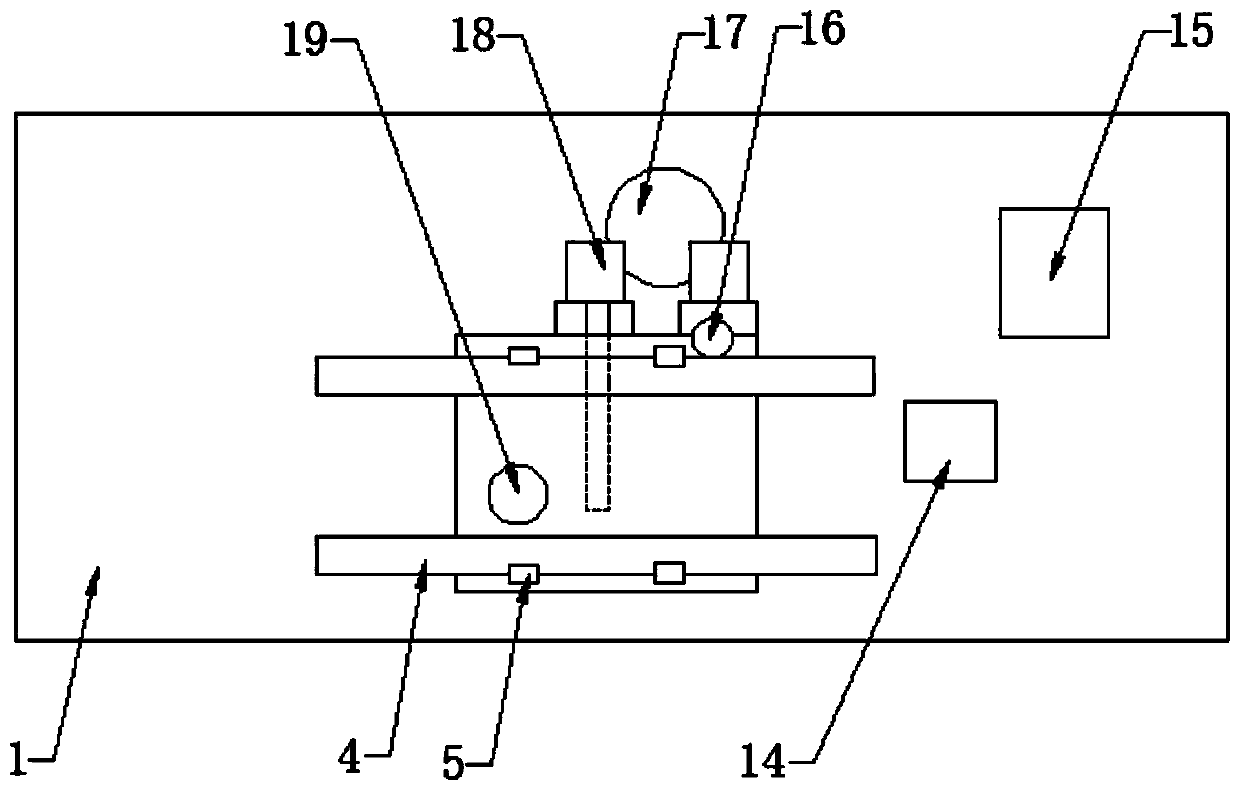

[0032] Such as Figure 1~2 As shown in the figure, an automatic and accurate equipment for repairing the wavy wear of subway curved rails is characterized in that the equipment includes a trolley that walks on the subway curved rails, and the trolley is provided with a positioning assembly that fixes it on the rails. The laser ranging sensor 10 for detecting the wavy wear of the subway curve rail and the grinding assembly 8 for repairing also include a driving assembly for driving the grinding assembly 8 to move in the X-axis direction, the Y-axis direction and the Z-axis direction and control components.

[0033] The drive assembly includes an X-axis drive assembly, a Y-axis drive assembly and a Z-axis drive assembly, wherein:

[0034] The X-axis drive assembly includes a rack and pinion mechanism in the X-axis direction, a slide rail in the X-axis direction, a slider 12 in the X-axis direction, a square connecting plate 5, a slide rail support plate 4 in the X-axis directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com