Hydropower station free-surface-pressurized flow tail water system

A technology of bright full flow and hydropower stations, applied in hydropower stations, hydroelectric power generation, water conservancy projects, etc., can solve the problems of difficulty in replenishing air for units and the inability to meet the requirements of setting up scale surge chambers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

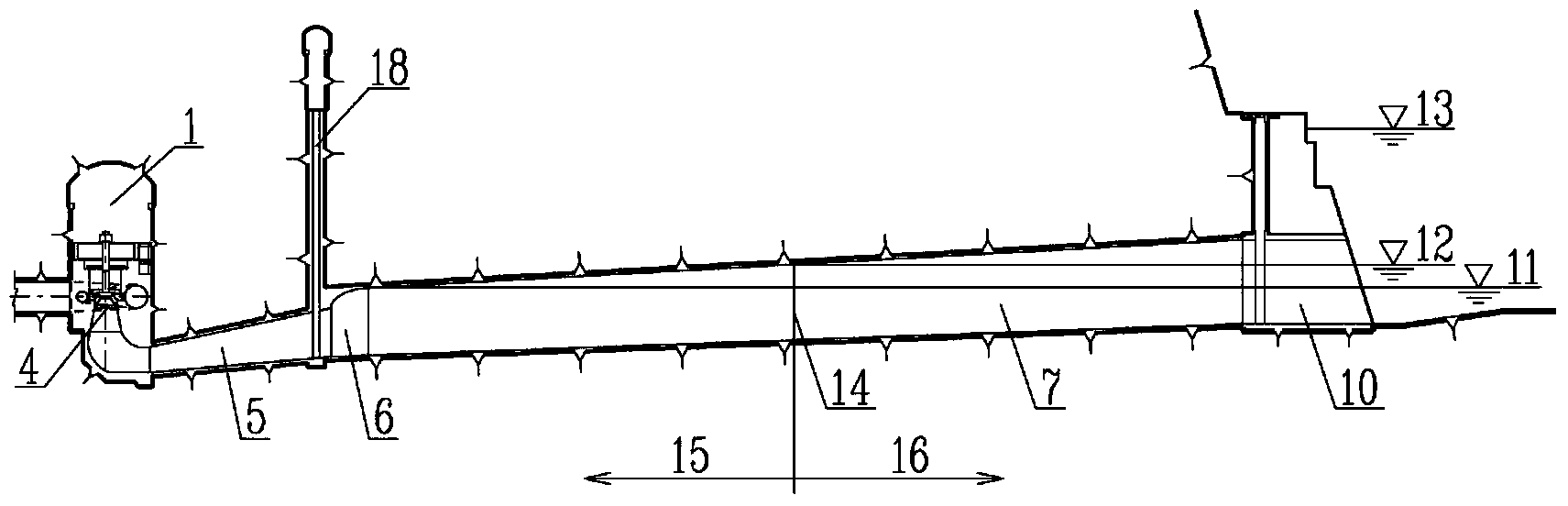

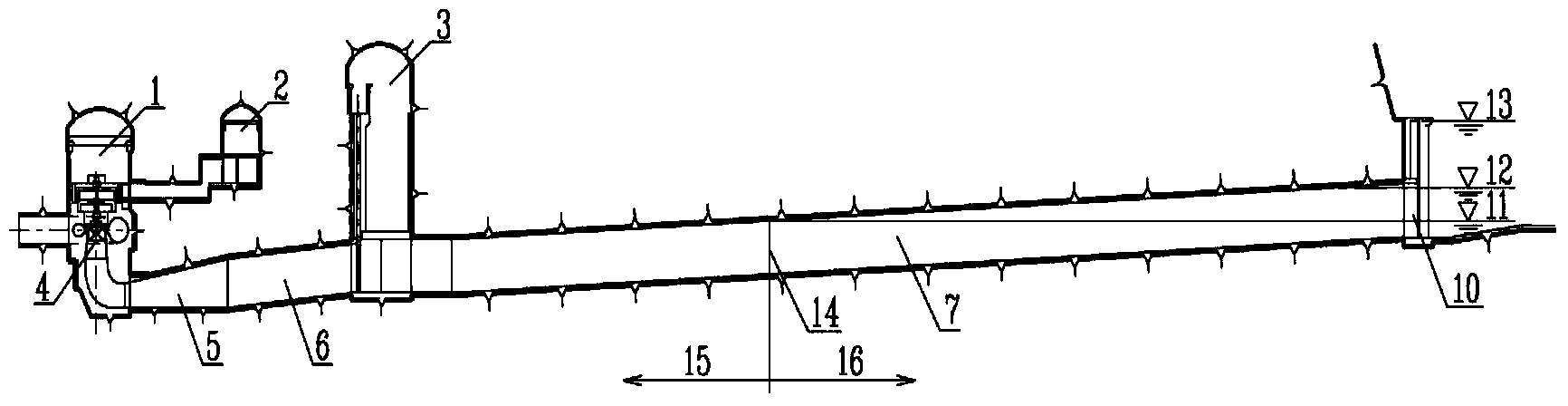

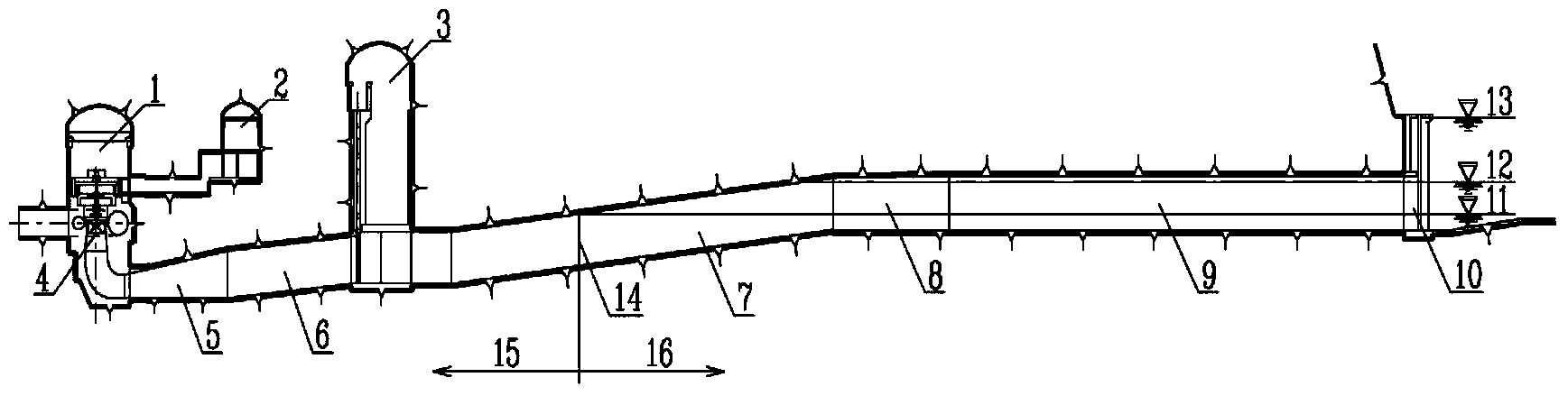

[0031] (1) Applied to the open flood tail water system when the length of the tail water system is 150m ~ 600m

[0032] When the length of the open and full flow tailrace system is 150m to 600m, the open and full flow tailrace tunnel can be used alone to ensure that the minimum absolute pressure (or vacuum) at the inlet of the draft tube meets the specifications and design requirements. Longitudinal section of tailwater tunnel see figure 1 . The tailrace system in this case includes a draft pipe (5), a connecting section (6) and an open and full flow tailrace tunnel, and the draft pipe (5) is connected to the open and full flow tailrace tunnel through the connecting section (6). If it is a multi-machine one-hole tailwater system, a unit inspection gate well (18) needs to be installed at the outlet of the draft pipe (5) to meet the maintenan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com