A condensing gas wall-hung boiler

A gas-fired wall-hung boiler, condensing technology, applied in the direction of the burner, combustion method, combustion type, etc., can solve the problems of condensed water cannot be discharged, the working sound is loud, the burner is extinguished, etc., and the sampling detection is simple and fast, the flame is stable, full burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

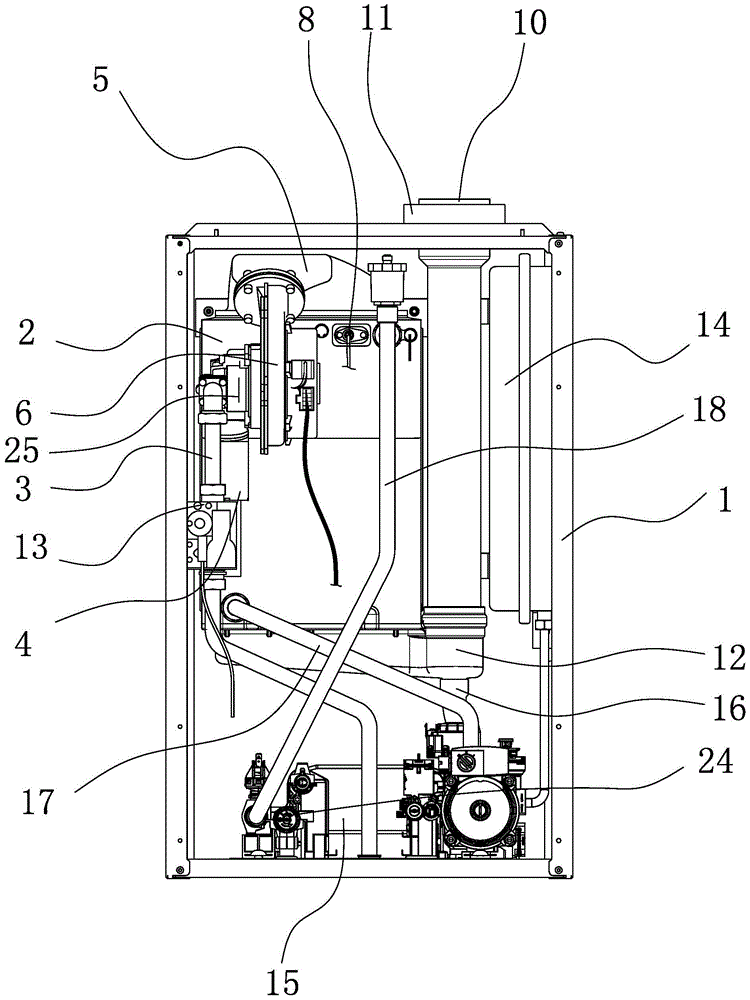

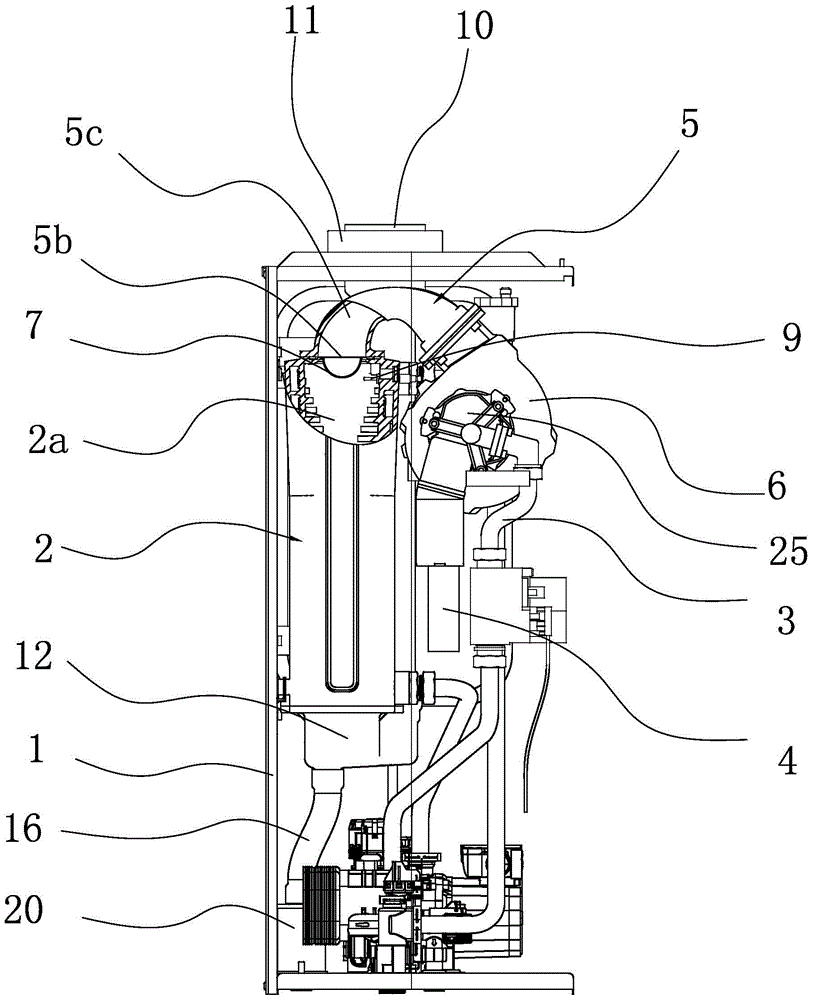

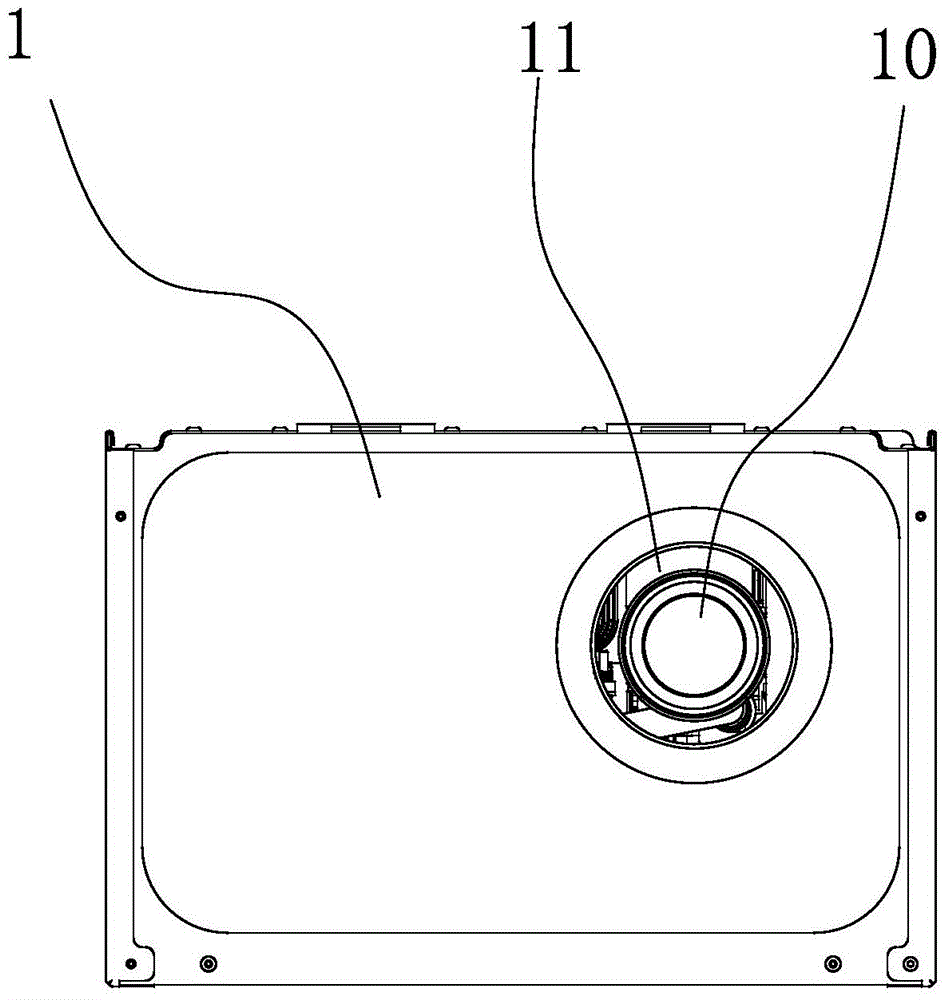

[0033] refer to figure 1 and figure 2 , this embodiment is a condensing gas wall-hung boiler, including a casing 1, and a main heat exchanger 2 arranged in the casing 1, a gas inlet pipe 3, an air inlet pipe 4, a combustion cover 5, a fan assembly 6, Condensing device, exhaust pipe 10, expansion tank 14 and plate exchanger assembly 15. The combustion cover 5 is arranged on the top of the main heat exchanger 2 and connected with the fan assembly 6 . One end of the gas inlet pipe 3 is used to feed gas, and the other end is connected with the fan assembly 6. The gas inlet pipe 3 and the air inlet pipe 4 are jointly connected on the premixer 25 at the front end of the fan assembly 6. The gas inlet pipe 3 is provided with A gas p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com