Special heat pipe device for ship

A heat pipe device and ship technology, which is applied in the ship field, can solve problems such as inability to realize circulation, not easy to dissipate heat, and consume energy for condenser heat dissipation, so as to achieve the effects of reducing energy consumption, increasing transmission speed, and speeding up transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

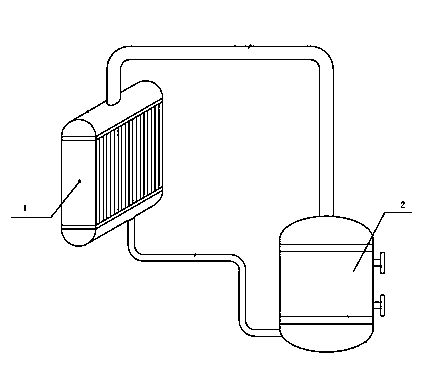

[0025] The present invention is based on the above structure, and the condenser 1 is arranged on the outside of the ship's chord, so that when the ship is running, the condenser can be washed by seawater to achieve cooling efficiency, and when the ship is stationary, the sea breeze can The blowing of the condenser can achieve the efficiency of cooling, and finally achieve the effect of reducing energy consumption; figure 1 As shown, the pipeline connecting the condenser 1 and the evaporator 2 includes an evaporation pipeline and a condensation pipeline, the condensation pipeline connects the lower surface of the condenser 1 and the evaporator 2, and the evaporation pipeline connects the upper surface of the condenser 1 and the evaporator 2; the heat pipe device Gravity heat pipe structure is adopted: the installation position of the condenser 1 is higher than that of the evaporator 2, so that it can rely on the height difference between the two and rely on the gravity of the me...

Embodiment 2

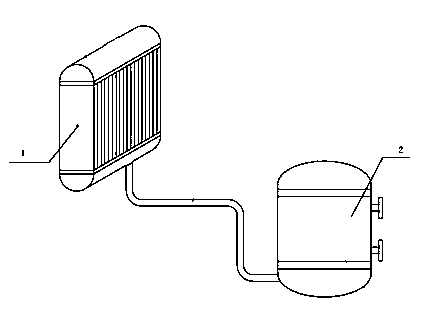

[0028] The present invention is on the basis of embodiment 1, as figure 2 As shown, a pipe connecting the condenser 1 and the evaporator 2 is also used. The use state of this device: when it transfers heat and dissipates heat, only one pipe is used to connect the condenser 1 and the evaporator 2, the evaporator 2 absorbs heat, flows the heat medium to the condenser 1, and dissipates the heat in the condenser 1 Transferred to the cold medium on the other side of the condensing end, the heat medium condenses into a liquid after releasing heat, and finally flows back to the evaporator 2 through the original pipeline.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com