Function module heat dissipation structure and case

A technology of functional modules and heat dissipation structure, which is applied in the construction of electrical equipment components, cooling/ventilation/heating transformation, electrical components, etc., can solve problems affecting equipment, circuits, shielding covers, slow heat dissipation, short circuit, burning, etc., to achieve simplification Installation steps, simple and optimized layout, and the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

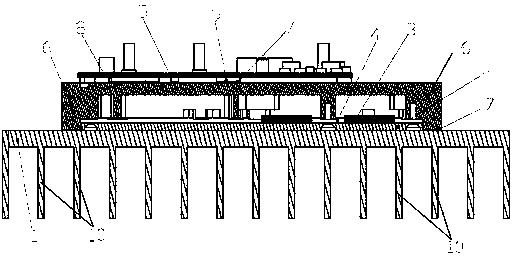

[0040] Functional module cooling structure, such as figure 1As shown, it includes a power amplifier substrate 2 for installation on the chassis 1, the power amplifier substrate 2 is connected with a first PCB board 4 with a power amplifier module 3, the first PCB board 4 is covered with a power amplifier shell 5, The outer edge of the power amplifier housing 5 is provided with a protruding portion 6, the protruding portion 6 extends along the surface direction of the first PCB board 4, and the extending direction is away from the center of the housing, and the protruding portion 6 extends to the chassis 1 at the same time The inner wall is in contact with the inner wall of the chassis 1.

[0041] As one of the implementations, the protruding portion 6 is continuously arranged along the outer edge of the power amplifier housing 5, forming a complete ring structure, and the protruding portion 6 and the power amplifier housing 5 are in an integrated structure. The part 6 is arra...

Embodiment 2

[0049] The heat dissipation case of the functional module is installed in the case with a power amplifier module 3 , and the power amplifier case 5 as described in the first embodiment is arranged on the power amplifier module 3 .

[0050] As one of the implementations, a plurality of power amplifier modules are arranged in the chassis 1, each of the power amplifier modules is correspondingly provided with the power amplifier housing, and each power amplifier module is correspondingly provided with a power amplifier housing, so as to improve the cooling efficiency.

[0051] As one of the implementation methods, such as figure 1 As shown, the outer wall of the chassis 1 is connected with heat dissipation teeth 10, and the heat dissipation teeth 10 are connected on the outer wall corresponding to the contact position between the raised portion 6 and the inner wall of the chassis 1. The heat dissipation teeth 10 can further improve the heat dissipation efficiency, and simultaneou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com