Evaporator automatic cleaning system

An automatic cleaning and evaporator technology, which is applied in flushing, cleaning of heat transfer devices, lighting and heating equipment, etc., can solve the problem that the pipes to be cleaned cannot be cleaned in a short time, increase labor intensity and production costs, and increase the difficulty of cleaning positioning and other problems, to achieve the effect of automatic cleaning, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

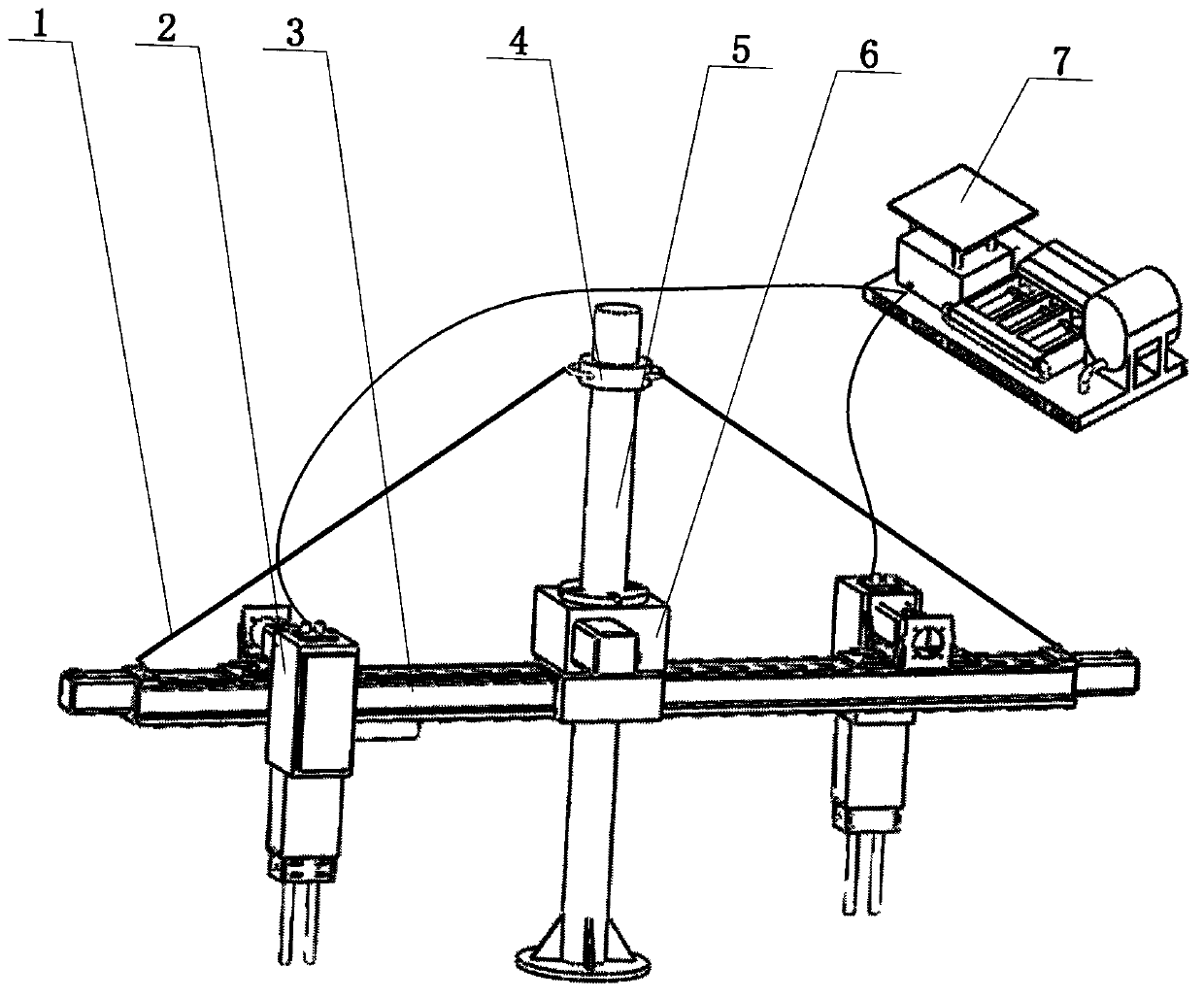

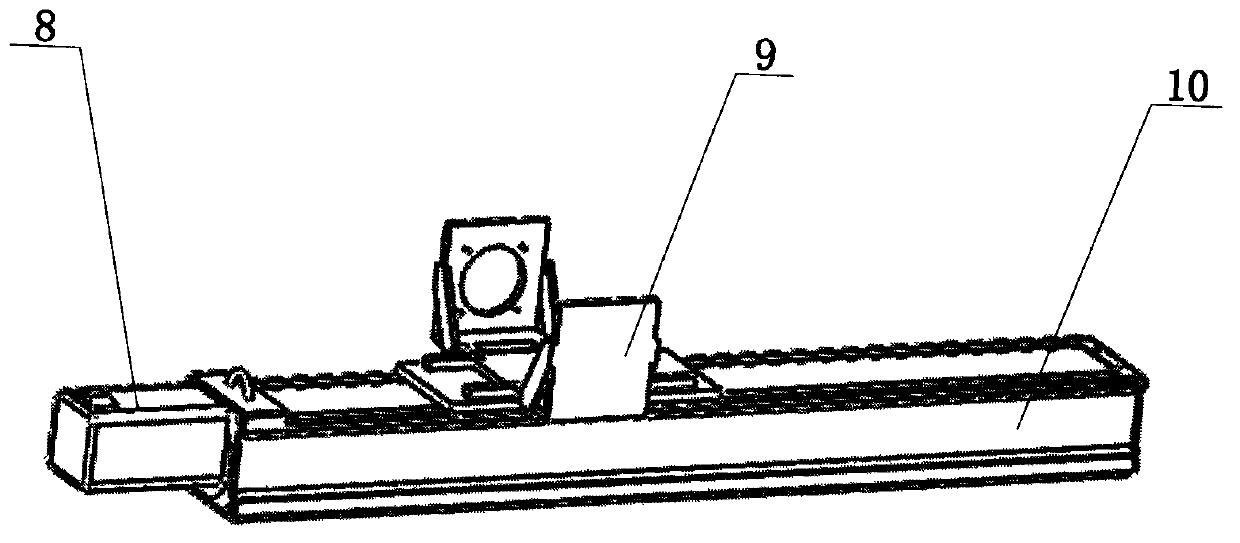

[0013] The horizontal linear slide mechanism 3 and the rotary table mechanism 6 are connected by bolts, and the rotary table mechanism 6 and the column 5 are connected by the bearing 4, and the system forms a cantilever beam structure. The structure is stable, and the motor bracket 9 is installed on the horizontal linear slide table 10; the high-pressure water jet unit 7 is connected with the fast tube feeder 2 through a high-pressure hose. The horizontal linear slide mechanism 3 is driven by the servo motor 8, so that the horizontal linear slide 10 can reciprocate smoothly; the fast tube feeder 2 is connected with the motor bracket 9 through bolts, and the positioning tube of the fast tube feeder is perpendicular to the horizontal plane. After being accurate, the fast tube feeder will quickly deliver the soft gun of high-pressure water jet to achieve the purpose of accurate positioning and quick cleaning; the rotary table mechanism 6 and the column 5 are connected by bolts, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com