Manipulator for testing capacitive touch screen

A technology of touch screen testing and manipulators, applied in the field of manipulators, can solve problems such as low efficiency and inconvenience of manual screen testing, and achieve the effects of easy maintenance, perfect functions and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

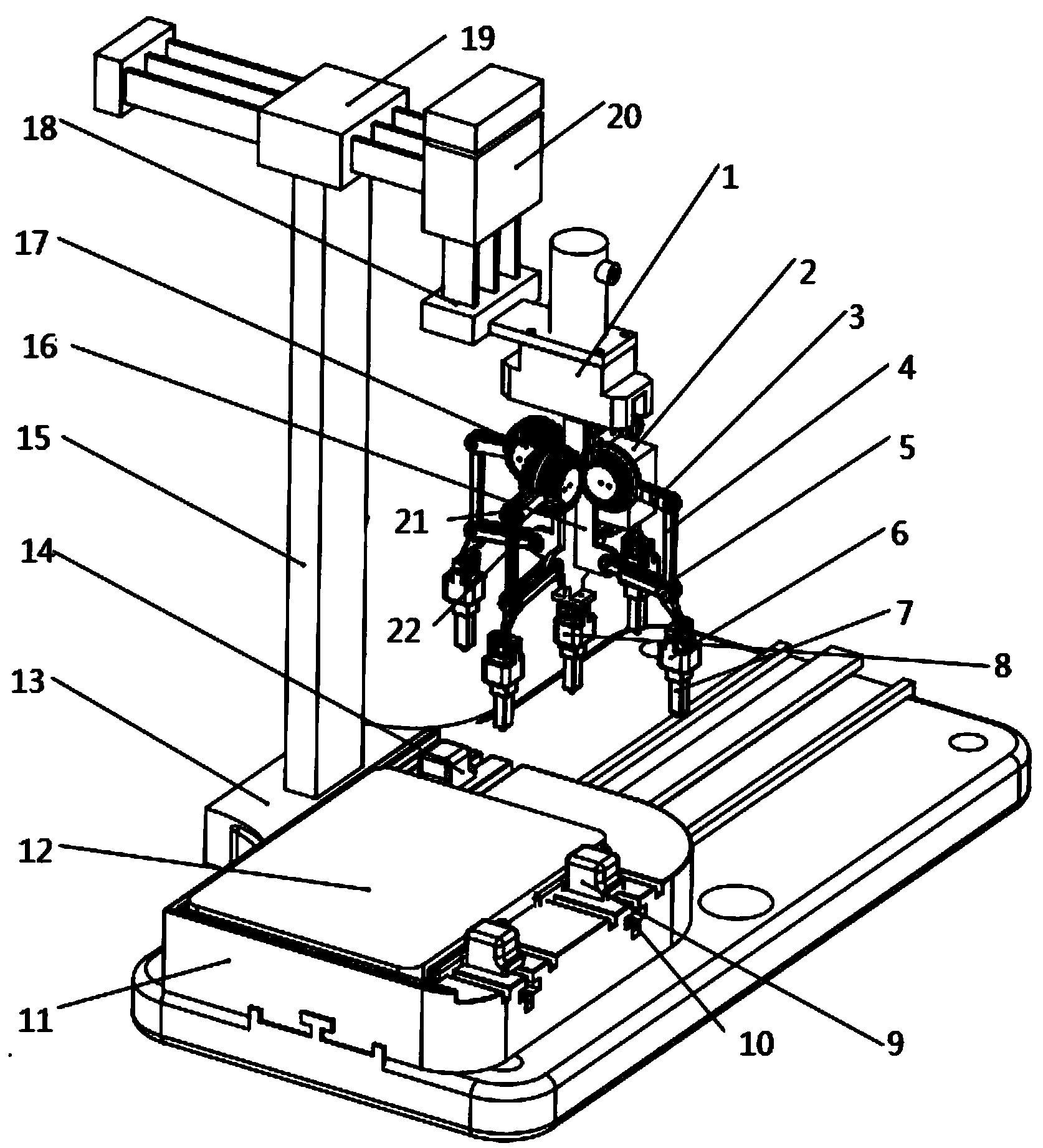

[0021] The present invention will be further explained below in conjunction with the accompanying drawings.

[0022] Such as figure 1 Shown, a kind of capacitive touch screen test manipulator is characterized in that, comprises support mechanism, transmission mechanism and control mechanism;

[0023] Described support mechanism comprises base 13, stand 15, claw support mechanism and moving fixture mechanism; Described movable fixture mechanism is positioned on base 13, and stand 15 bottoms are vertically fixed on base 13 one side; top of frame 15;

[0024] The claw support mechanism comprises a Y-axis guide rail fixed block 19, a Y-axis guide rail, a Z-axis guide rail fixed block 2, a Z-axis guide rail, a Z-axis guide rail moving block 18, a manipulator base 1 and a claw frame 16; the Y-axis guide rail is fixed The block 19 is fixed on the top of the stand 15, and the Y-axis guide rail can move horizontally along the Y-axis guide rail fixed block 19; the Z-axis guide rail fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com