Method for producing rice noodles with accurate metering and packaging

A production method and measurement and packaging technology, which is applied in the directions of packaging, transportation and packaging, and special packaging objects, etc., can solve the problems of easily scalding the operator's hands, hidden safety and hygiene hazards, and large amounts of sewage discharge, so as to avoid occupational safety hazards and measure The effect of accuracy and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

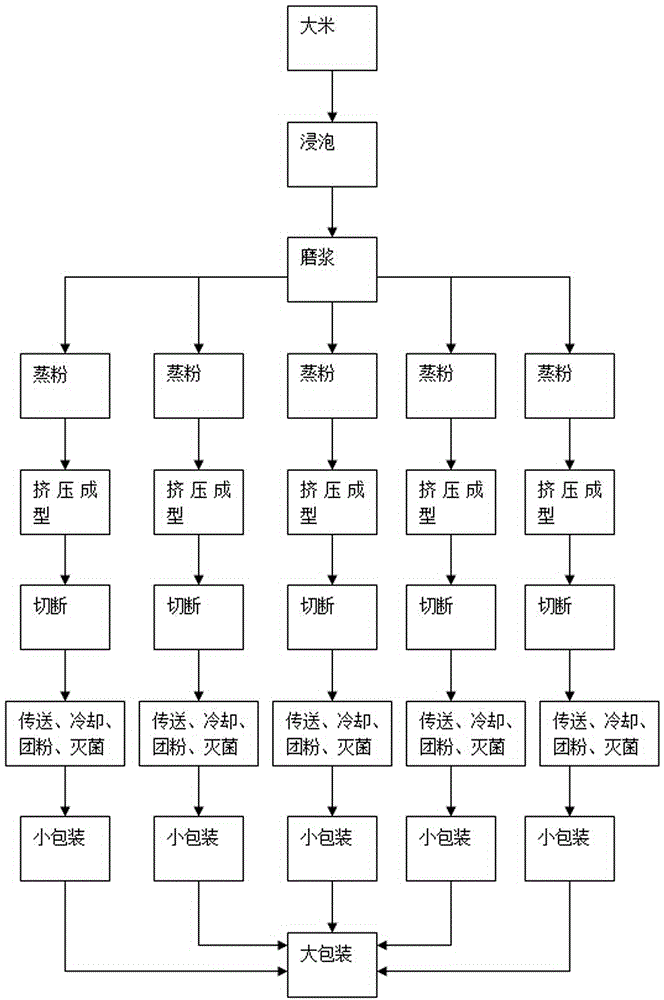

[0030] See figure 1 .

[0031] The flow process of this implementation method is the same as the traditional method in the selection, soaking and defibrination of raw rice. After refining, the slurry is divided into five equal parts (determined through production capacity design and calculation, so that the rice noodles obtained from each branch unit at the end will be two or three when the cut length is 15~30cm), and after each equal part is A branch unit, each branch unit is steamed, extruded, cut, conveyed, cooled, powdered, sterilized, small packaged, and finally each branch unit is uniformly packaged.

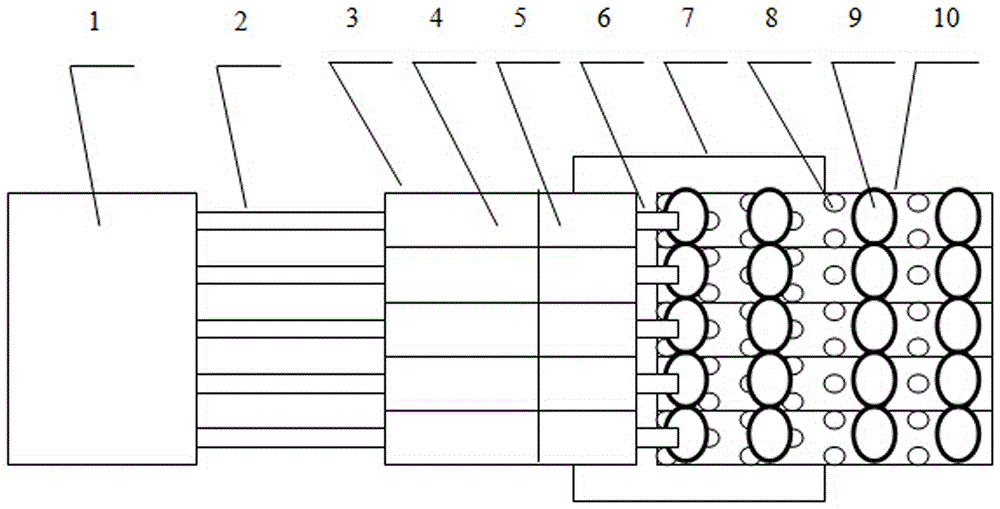

[0032] figure 2 image 3 The flow of equipment and facilities implementing the method of the present invention is given. from figure 2 The present invention can be understood more intuitively. After being refined by the refiner 1, the slurry is sent to the steamer 3 through five pipes 2 of the same specification, steamed into rice cakes by five steaming compartment...

Embodiment 2

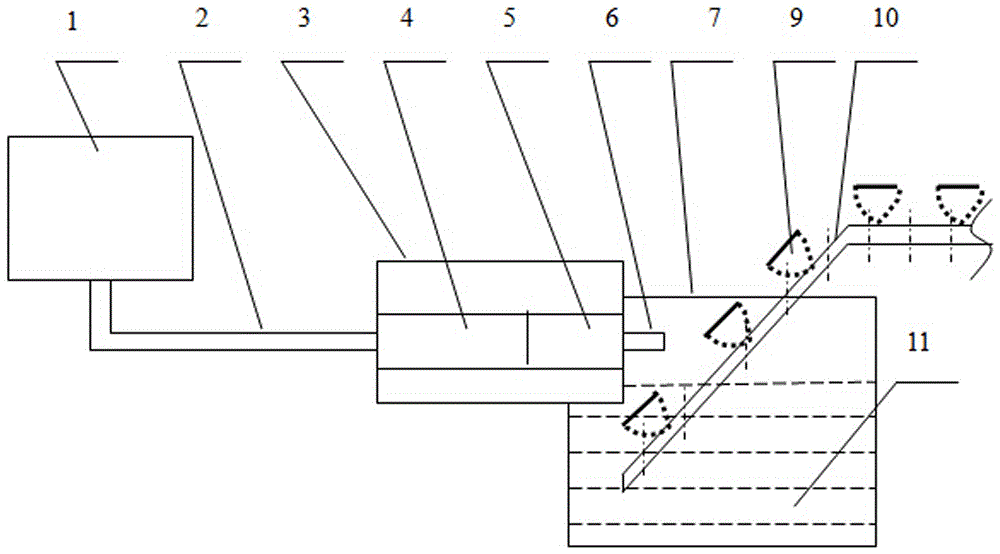

[0036] See Figure 5 . This embodiment is basically the same as Embodiment 1. The difference is that the slurry is divided into three equal parts (determined through production capacity design and calculation, so that the rice noodles obtained from each branch unit at the end will be two or three when the cut length is 15~30cm), and after each equal part is A branch unit, each branch unit is steamed, extruded, cut, conveyed, cooled, powdered, sterilized, small packaged, and finally each branch unit is uniformly packaged. And each branch unit is separate and independent. That is, after refining 1, it is divided into three independent branch units, pipeline 2, steamer 15, steamer 16, extruder 17 extrusion, extrusion head 18 and conveyor belt 22 are three sets. A water filter hole 20 and a receiving bowl 21 are also arranged on each conveyer belt 22 . Three independent branch units share the cooling pool 19 .

[0037] Every conveyer belt 22 transmits the rice noodle group to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com