a coffee machine

A technology for coffee machines and coffee powder cups, applied in mechanical equipment, engine components, functional valve types, etc., can solve the problems of unstable coffee quality, troublesome maintenance and use, and inconvenient promotion and use, and achieve simplified operation, low cost, The effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

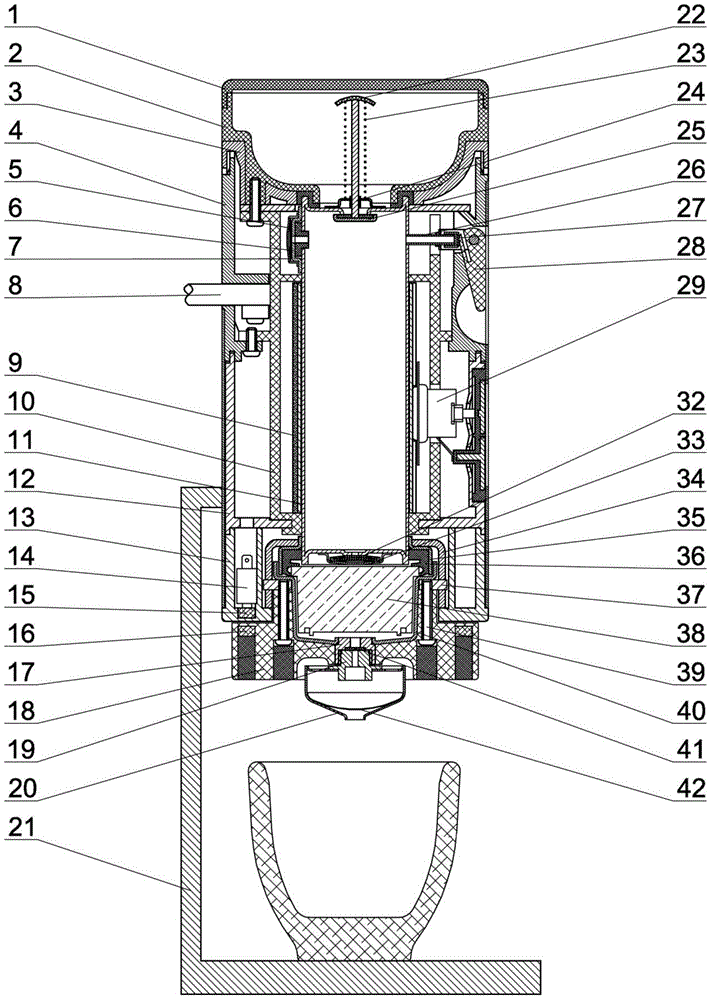

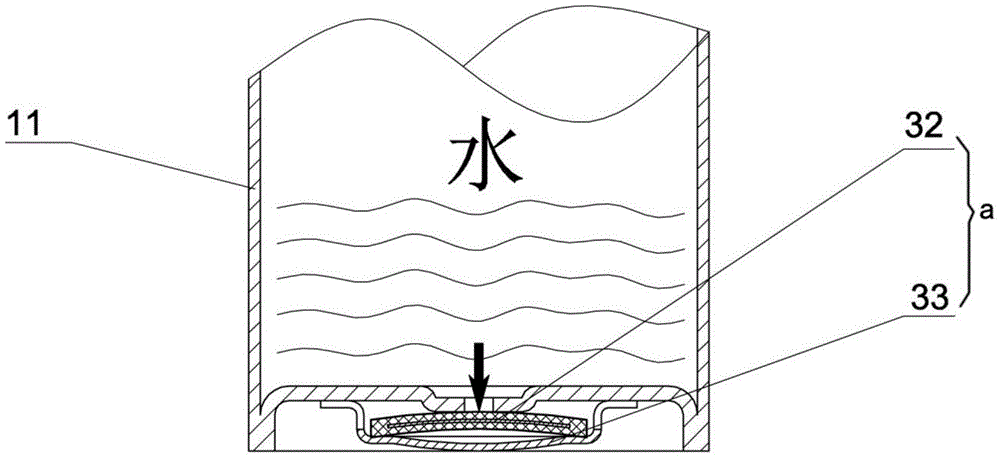

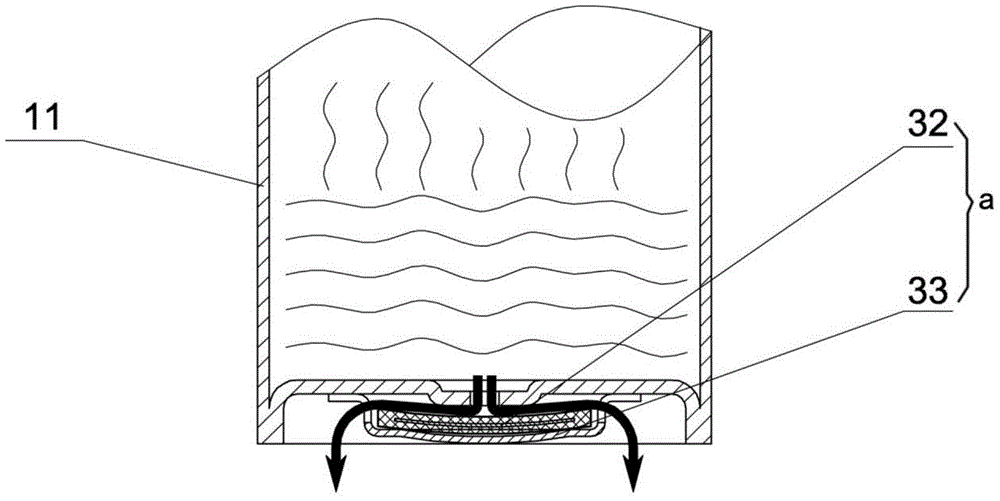

[0039] figure 2 and image 3 It is a schematic diagram of the working state of an automatic drainage mechanism of the coffee machine according to Embodiment 1 of the present invention, combined below figure 1 , figure 2 and image 3 The automatic drain mechanism a will be described.

[0040] Such as figure 1 , figure 2 and image 3 As shown, an automatic drainage mechanism a is provided at the drain outlet of the inner pot 11, and the automatic drain mechanism a can open or block the drain outlet according to the ambient temperature at the drain outlet of the inner pot 11. The drain outlet mentioned here The ambient temperature specifically refers to the temperature sensed or borne by the automatic drainage mechanism a.

[0041] In this embodiment, the automatic drain mechanism a includes a drain valve cover 33 and a drain valve plate 32 . Wherein, the drain valve cover 33 is fixed at a fixed distance relative to the drain port. For example, the drain valve cover 3...

Embodiment 2

[0051] Figure 4 and Figure 5 It is a schematic diagram of the working state of an automatic steam exhaust mechanism of a coffee machine according to Embodiment 2 of the present invention, combined below figure 1 , Figure 4 and Figure 5 The automatic exhaust mechanism b will be described.

[0052] Such as figure 1 , Figure 4 and Figure 5 As shown, on the side wall of the inner pot 11 close to the water inlet, there are steam exhaust ports for discharging steam and an automatic exhaust port for opening or blocking the steam exhaust port according to the ambient temperature at the steam exhaust port of the inner pot 11. The steam exhaust mechanism b, here, the ambient temperature at the steam exhaust port specifically refers to the temperature sensed or borne by the automatic steam exhaust mechanism b.

[0053] In this embodiment, the automatic exhaust mechanism b includes an exhaust sheet seat 6 , an exhaust sheet cover 7 and an automatic exhaust sheet 5 . The stea...

Embodiment 3

[0063] In this embodiment 3, refer to figure 1 The coffee machine is equipped with a coffee powder cup 40 for holding coffee powder or a coffee capsule 38 below the water outlet of the inner pot 11. The coffee powder cup 40 is sealed and connected with the inner pot 11, and a coffee powder cup 40 is provided at the bottom of the coffee powder cup 40 for A nozzle mechanism that controls the outflow of coffee according to the pressure in the ground coffee cup 40 .

[0064] Such as figure 1 As shown, a sealing support ring 35 covered with a locking member 34 is welded at one end of the water outlet of the inner pot 11 , and a sealing ring 36 is arranged in the sealing supporting ring 35 for installing the coffee powder cup 40 under the inner pot 11 When playing a sealing role. The ground coffee cup 40 is tightly fastened on the cup buckle 37 used to cooperate with the sealing support ring 35 , and the ground coffee cup holder 18 is fastened on the cup buckle 37 by screws 39 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com