Active exciting agent atomization device for metal tailing grinding system

A technology of active activators and metal tailings, which is applied in the direction of injection devices, liquid injection devices, etc., can solve the problems of large loss, difficulty in active activators, uniform mixing of raw materials, etc., to achieve reduced volatilization and loss, high activity index, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further describe the present invention in detail, it will be described below in conjunction with the accompanying drawings and specific embodiments. In particular, the following examples are only for explanation of the present invention and the present invention is not limited to the following examples.

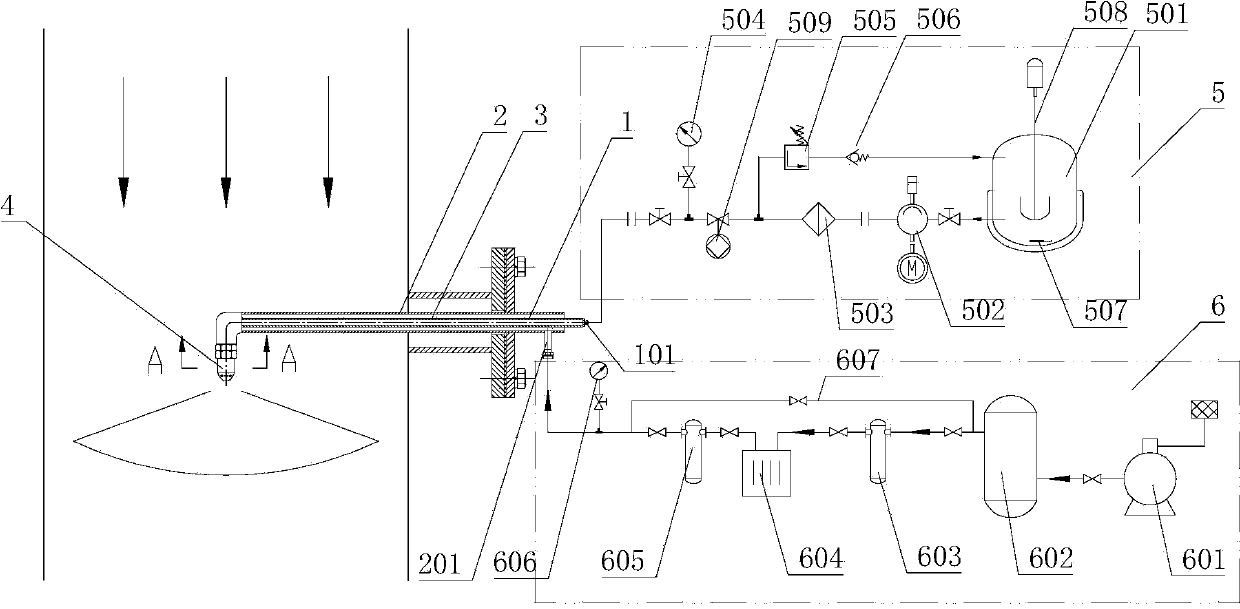

[0019] See Figure 1-3 , an active activator atomization device for metal tailings grinding system, which consists of the following parts:

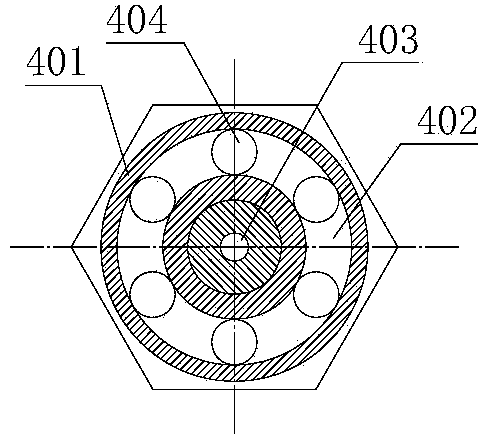

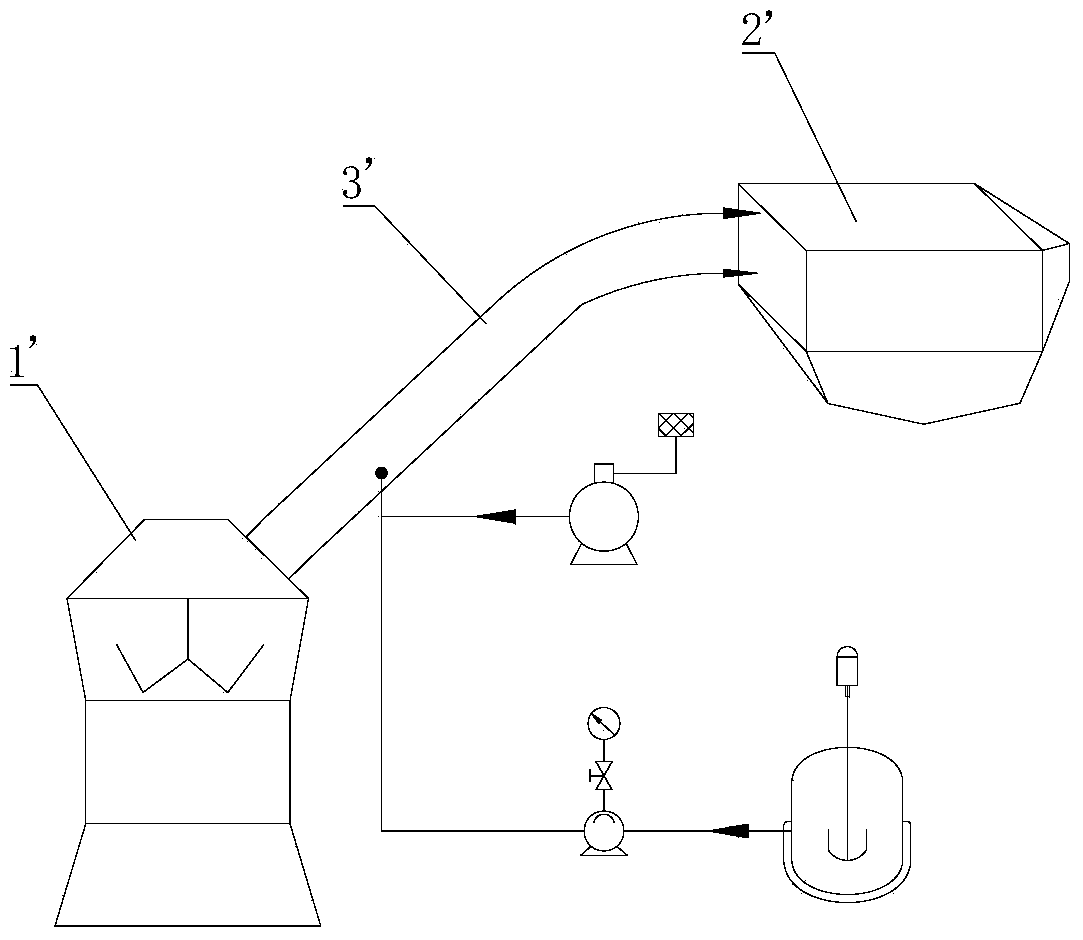

[0020] It includes a spray gun welded by an inner tube 1 and an outer tube 2. An air inlet ring chamber 3 is formed between the outer sleeve and the inner pipe, one end of the air inlet ring chamber is a closed end, and the other end is an open end. The spray gun is installed on the connecting pipe 3 between the vertical mill 1 and the bag filter 2, and its open end stretches into the connecting pipe, and its closed end is located outside the connecting pipe. Specifically, an opening for inserting a spray gun is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com