Steel tube cold-drawing machine

A technology of cold drawing machine and steel pipe, which is applied in the field of steel pipe cold drawing machine, can solve problems such as low efficiency and affecting enterprise benefits, and achieve the effects of improving efficiency, saving time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

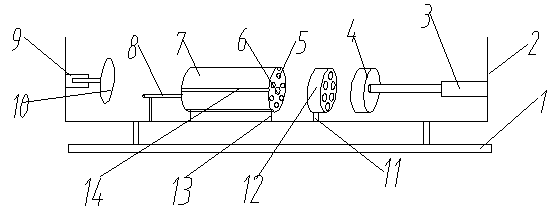

[0020] Such as figure 1 Described a kind of steel pipe cold drawing machine comprises base 1, frame 2, is provided with drawing die base 12 on described frame 2, and described drawing die base 12 becomes a disc-shaped structure, is arranged on it There are a plurality of mounting holes, a mold is arranged in the mounting holes, the die base 12 is installed on the frame 2 through the die support 11, and the die base support 11 is fixed on the on rack 2.

[0021] The two ends of the drawing die base 12 are respectively provided with a steel pipe positioning seat 7 and a drawing die clamp 4. The steel pipe positioning seat 7 is a cylindrical structure, and a plurality of steel pipe positioning holes 5 are arranged on it. The number of positioning holes 5 is the same as the number of mounting holes arranged on the drawing die base 12. In this embodiment, there are 6 steel pipe positioning holes 5, and the 6 steel pipe positioning holes are evenly distributed on the steel pip...

Embodiment 2

[0025] As an effective supplement to Embodiment 1 of the present invention, a positioning seat support bar 8 is provided on the frame 2, and the positioning seat support bar includes a vertical bar and a horizontal bar, and the vertical bar is connected to the described The frames are connected by welding or riveting, the center of the steel pipe positioning seat 7 is provided with a positioning seat support hole 6, and the horizontal bar is connected with the positioning seat support 6. When the steel pipe support seat 7 is installed, it is only necessary to put the positioning seat support hole 6 on the steel pipe support seat 7 on the horizontal bar, and rotate the steel pipe support seat 7 at the same time, only need to align the positioning clamp 13 with the limit slot Live on the line, just can complete the location of steel pipe support seat 7.

[0026] The steel pipe cold drawing machine of the present invention can draw multiple steel pipes at one time by setting mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com