Mechanical production process for series large high-velocity roller

A manufacturing process and technology of high-speed rollers, applied in printing, printing devices, etc., can solve problems such as difficult to meet the requirements of high-speed roller rotation accuracy and stability, reduce manufacturing costs, ensure rotation accuracy and stability, and ensure manufacturing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

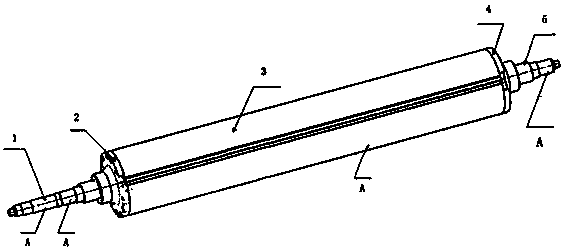

[0026] A series of large high-speed rollers ( figure 1 ) manufacturing process, including roller split manufacturing process, parts material selection and manufacturing process, roller assembly and processing technology.

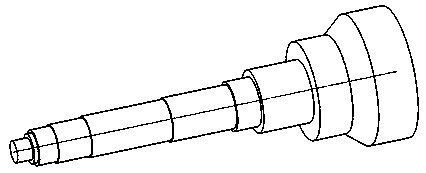

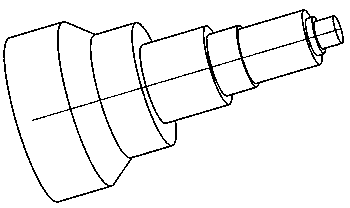

[0027] Roller split manufacturing process is to split the roller into left and right support shafts 1, 5, left and right end covers 2, 4 and cylinder body 3 five components ( figure 1 ), the five parts are separately semi-finishing and then combined and then processed. First, the left and right support shafts 1, 5 and the left and right end covers 2, 4 are respectively combined into left and right supports ( Figure 5 , Image 6 ) and finish machining, and then assemble the left and right supports with the cylinder body 3 to form a roller ( figure 1 ), and then carry out overall finishing, dynamic balancing, finishing and final hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com