Technology for avoiding wrinkling occurring in aluminum foil intaglio printing

A gravure printing and aluminum foil technology, applied in the field of printing ink, can solve the problems of poor plate shape of incoming materials, incorrect plate shape adjustment, and unequal roll shape, and achieve the effects of low cost, simple process and suitable for large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The invention provides a process for solving the wrinkling of aluminum foil gravure printing, which comprises the following steps:

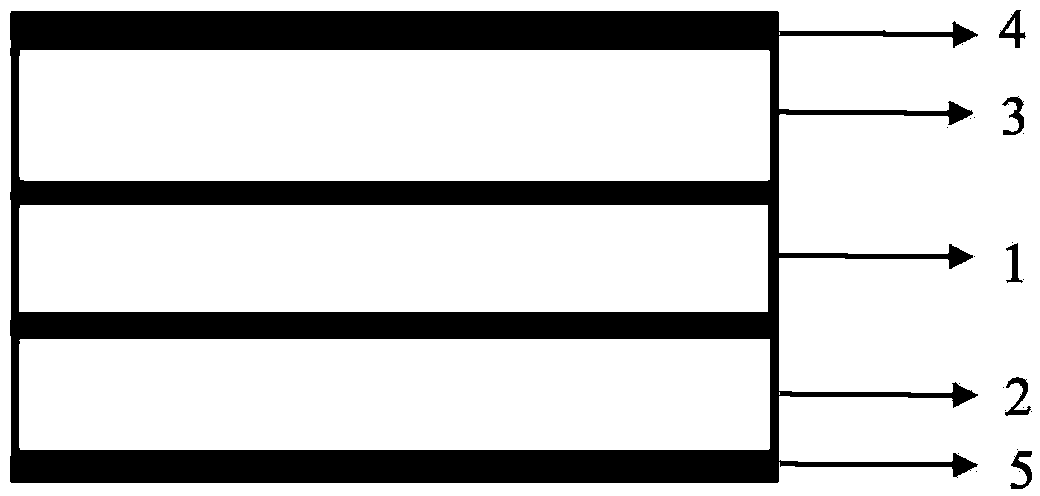

[0028] Step 1, performing corona treatment on both sides of the PET film 1 with a thickness of 10-20 μm;

[0029] Step 2: Coating polyurethane composite glue on the corona surfaces on both sides of the PET film 1, and then attaching aluminum foils 2 and 3 with a thickness of 5 to 10 μm on the surface of the polyurethane composite glue;

[0030] Step 3, attaching a layer of silicone protective film 5 with a viscosity of 1 gf on the surface of one of the aluminum foils 2;

[0031] Step 4, printing ink 4 on the other surface of the aluminum foil 3 through the gravure printing rubber roller device, and then drying the ink;

[0032] Step 5, peeling off the silica gel protective film 5 .

Embodiment 2

[0034] The invention provides a process for solving the wrinkling of aluminum foil gravure printing, which comprises the following steps:

[0035] Step 1, performing corona treatment on both sides of the PET film 1 with a thickness of 10-20 μm;

[0036] Step 2: Coating polyurethane composite glue on the corona surfaces on both sides of the PET film 1, and then attaching aluminum foils 2 and 3 with a thickness of 5 to 10 μm on the surface of the polyurethane composite glue;

[0037] Step 3, attaching a layer of silicone protective film 5 with a viscosity of 3gf on the surface of one of the aluminum foils 2;

[0038] Step 4, printing ink 4 on the other surface of the aluminum foil 3 through a gravure printing rubber roller device, and then drying the ink 4;

[0039] Step 5, peeling off the silica gel protective film 5 .

Embodiment 3

[0041] The invention provides a process for solving the wrinkling of aluminum foil gravure printing, which comprises the following steps:

[0042] Step 1, performing corona treatment on both sides of the PET film 1 with a thickness of 10-20 μm;

[0043] Step 2: Coating polyurethane composite glue on the corona surfaces on both sides of the PET film 1, and then attaching aluminum foils 2 and 3 with a thickness of 5 to 10 μm on the surface of the polyurethane composite glue;

[0044] Step 3, attaching a layer of silica gel protective film 5 with a viscosity of 5 gf on the surface of one of the aluminum foils 2;

[0045] Step 4, printing ink 4 on the other surface of the aluminum foil 3 through a gravure printing rubber roller device, and then drying the ink 4;

[0046] Step 5, peeling off the silica gel protective film.

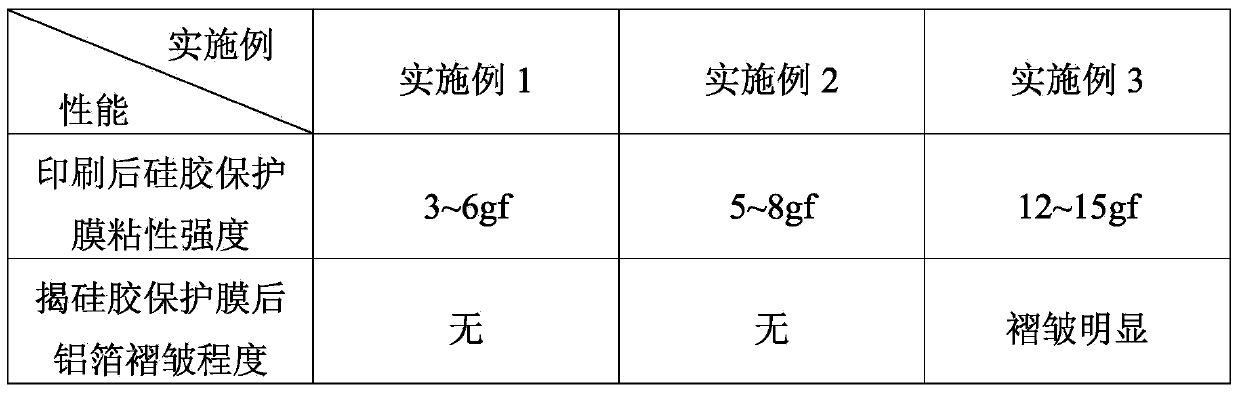

[0047] The table summarizes the viscosity of the silicone protective film and the wrinkle degree of the aluminum foil after the silicone protective film is r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com