Automatic shielding wire paying off device

A technology of pay-off device and shielded wire, which is applied in the direction of transportation and packaging, delivery of filamentous materials, cables with twisted strands or twisted strands, etc., which can solve the loss of human, material and financial resources, the amplification of negative effects, Reduce product advantages and other issues to achieve the effects of saving finished products, increasing stability, and avoiding bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

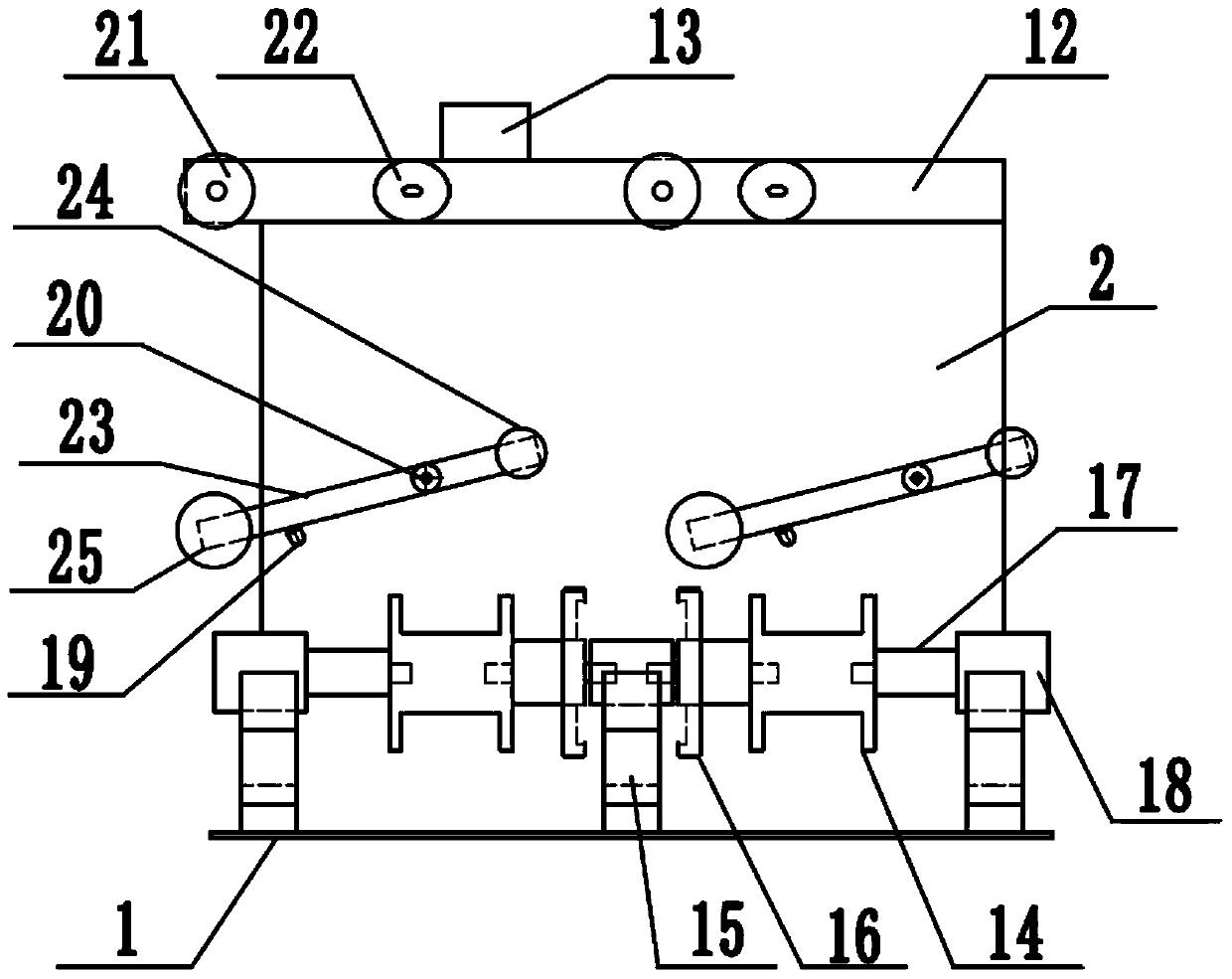

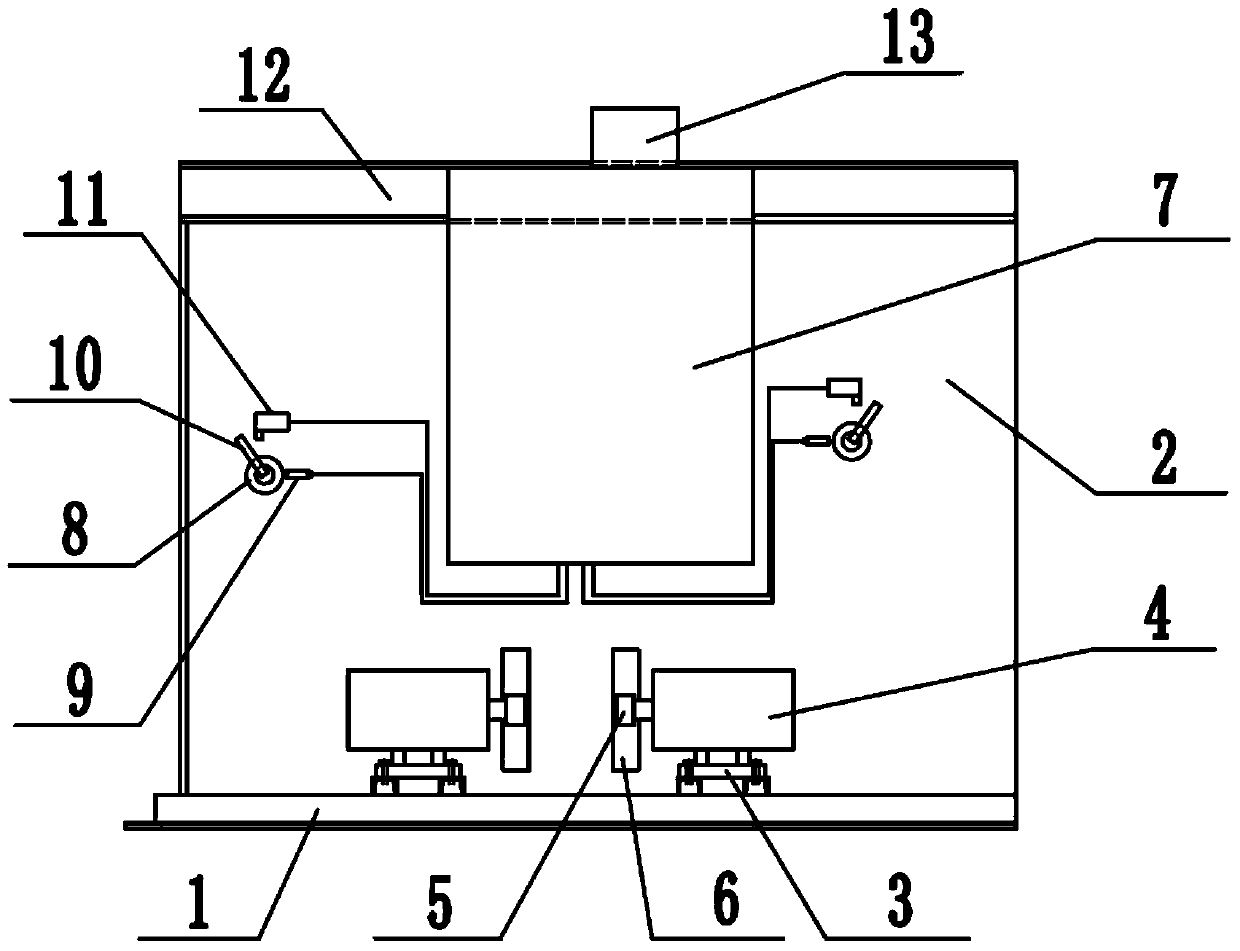

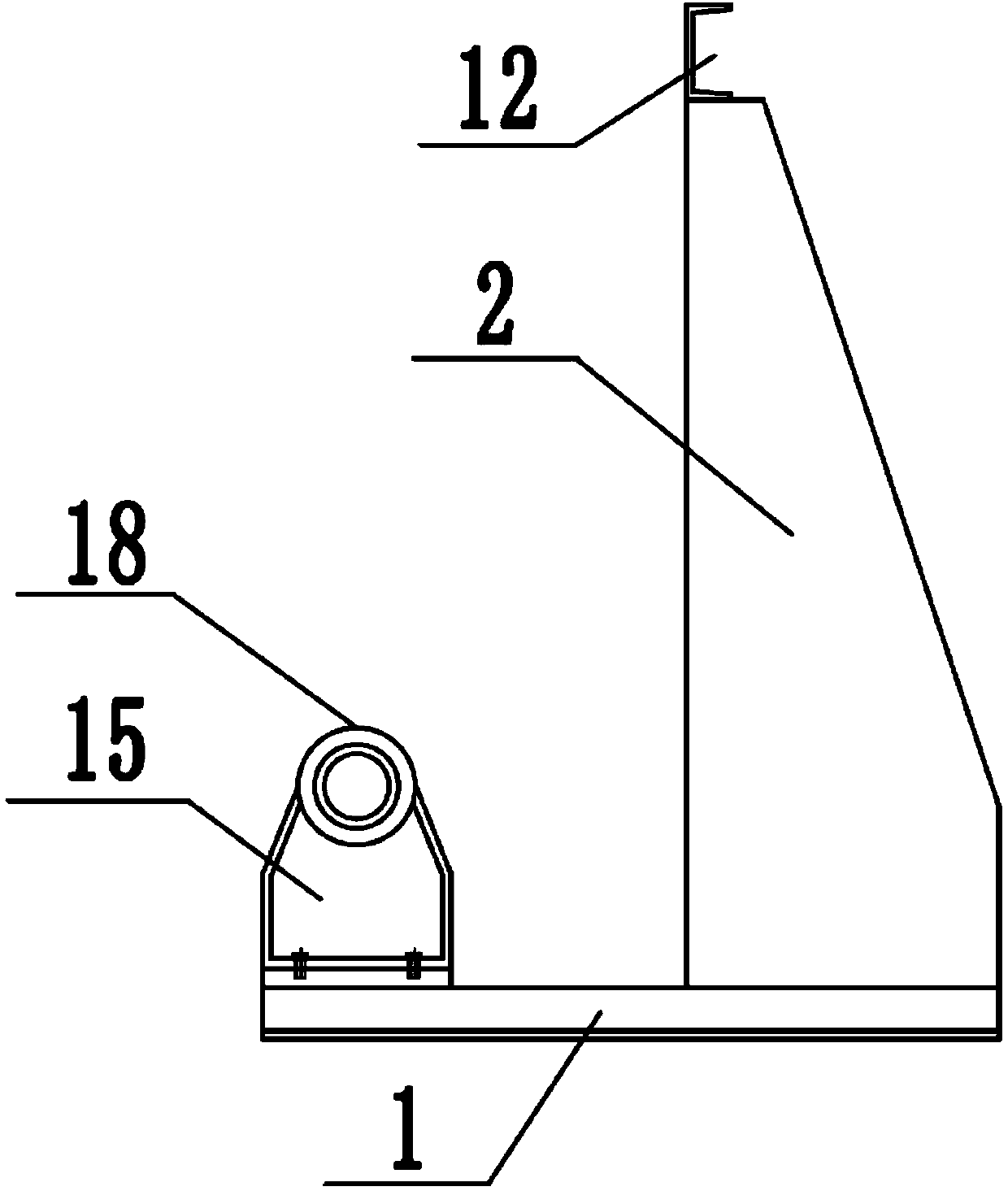

[0017] Such as Figure 1-3 As shown, the present invention relates to a shielded wire automatic pay-off device, comprising a base 1 and a trapezoidal fixing plate 2 arranged on the base 1, a row of bearing seats 15 are evenly arranged on the base 1, and the top of the bearing seats 15 is set Axle sleeve 18, and the rotating shaft 17 that two ends are penetrated in the shaft sleeve 18 is provided between adjacent bearing blocks 15, and each rotating shaft 17 is provided with pay-off tube 14 and large pulley 16, and described trapezoidal fixed Plate 2 is provided with several rectangular holes 6 arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com