A method for extracting titanium from red mud

A technology of red mud and titanic acid, which is applied in the field of red mud hydrometallurgy, can solve the problems of low purity of titanium dioxide products, difficulties in acid wastewater treatment, and low pH value of leachate, and achieve the results of less impurities in hydrolyzed products, accelerated destruction, and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

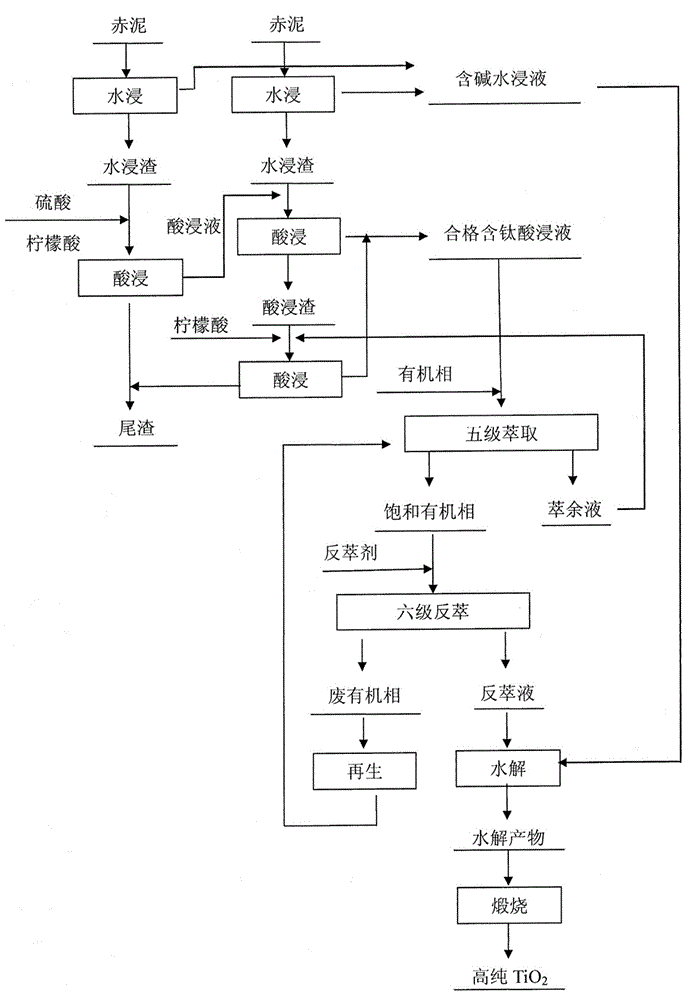

Image

Examples

Embodiment 1

[0024] The water leaching slag is discharged into the acid leaching tank, and the mixed solution of sulfuric acid solution and citric acid is added according to the liquid-solid mass ratio of 4 ~ 8mL / g to carry out secondary acid leaching; the mixed solution of the sulfuric acid solution and citric acid is obtained by 3~4mol / L sulfuric acid solution and citric acid with a mass fraction of 6~8% are mixed; then stirred for 60~120min under the condition of stirring intensity of 250~400r / min and leaching temperature of 70~100℃, solid-liquid Separation to obtain tailings and acid leaching solution, acid leaching solution mixed with new red mud water leaching residue for secondary acid leaching, solid-liquid separation to obtain acid leaching residue and qualified titanium-containing acid leaching solution, acid leaching residue is mixed with raffinate, After adding citric acid with a mass fraction of 6-8%, carry out secondary acid leaching, and obtain tailings and qualified titanic ...

Embodiment 2

[0026]The water leaching slag is discharged into the acid leaching tank, and the mixed solution of sulfuric acid solution and citric acid is added according to the liquid-solid mass ratio of 4 ~ 8mL / g to carry out secondary acid leaching; the mixed solution of the sulfuric acid solution and citric acid is obtained by 4~5mol / L sulfuric acid solution and citric acid with a mass fraction of 4~6% are mixed; then stirred for 45~90min under the condition of stirring intensity of 300~500r / min and leaching temperature of 70~100℃, solid-liquid Separation of tailings and acid leaching solution, acid leaching solution mixed with new red mud water leaching residue for secondary acid leaching, solid-liquid separation to obtain acid leaching residue and qualified titanium-containing acid leaching solution, acid leaching residue and raffinate mixed , after adding citric acid with a mass fraction of 4-6%, carry out secondary acid leaching, solid-liquid separation to obtain tailings and qualifi...

Embodiment 3

[0028] The water leaching slag is discharged into the acid leaching tank, and the mixed solution of sulfuric acid solution and citric acid is added according to the liquid-solid mass ratio of 4 ~ 8mL / g to carry out secondary acid leaching; the mixed solution of the sulfuric acid solution and citric acid is obtained by 5~6mol / L sulfuric acid solution and citric acid with a mass fraction of 2~4% are mixed; then stirred for 30~60min under the condition of stirring intensity of 400~600r / min and leaching temperature of 70~100℃, solid-liquid Separation of tailings and acid leaching solution, acid leaching solution mixed with new red mud water leaching residue for secondary acid leaching, solid-liquid separation to obtain acid leaching residue and qualified titanium-containing acid leaching solution, acid leaching residue and raffinate mixed , after adding citric acid with a mass fraction of 2-4%, carry out secondary acid leaching, solid-liquid separation to obtain tailings and qualif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com