Stripping device and stripping method for preparing copper-plated tube for air-conditioning compressor

An air-conditioning compressor and deplating technology, which is applied in the processing field of copper-plated pipes for air-conditioning compressors, can solve problems such as damaging the surface of the pipe body, affecting the work of the compressor, and poor processing, and achieves convenient recycling, simple structure, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

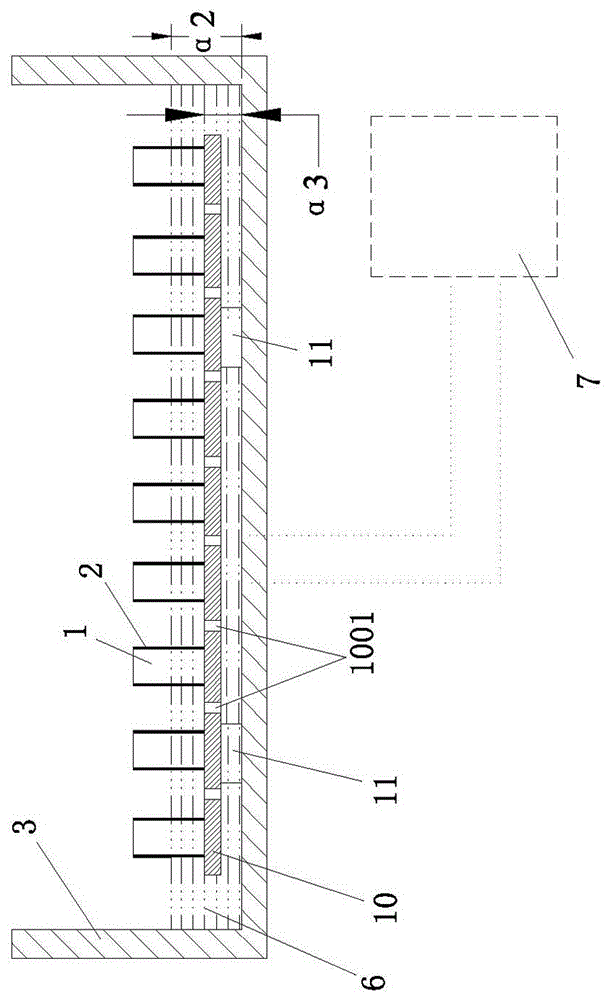

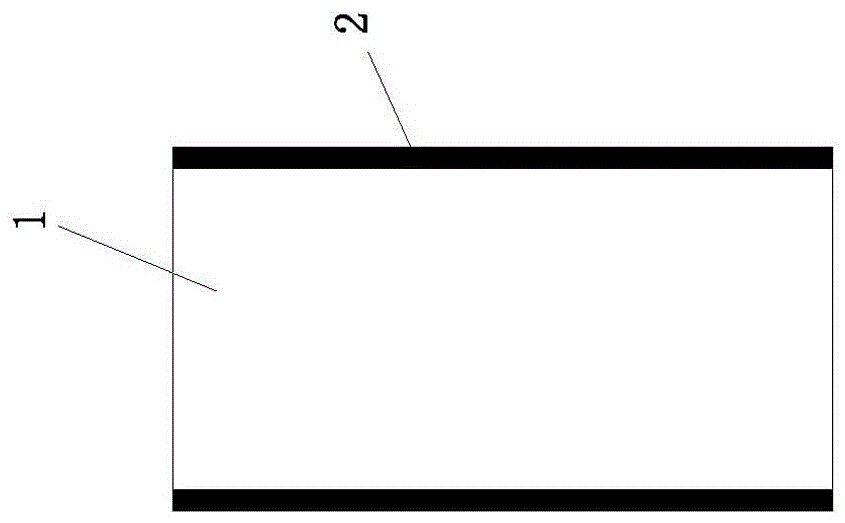

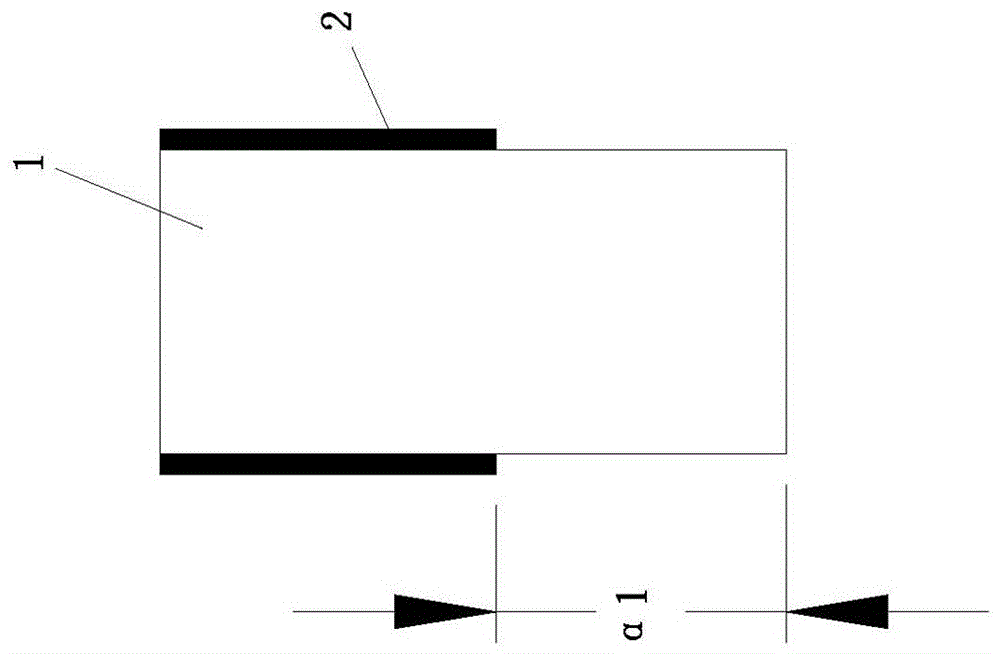

[0032] Such as Figure 1 to Figure 5 As shown, the deplating device for preparing copper-plated pipes for air-conditioning compressors includes a formed semi-finished pipe body 1, and the semi-finished pipe body 1 is completely covered with an electroplated copper layer 2. It is characterized in that it also includes a deplating pool 3, The base 10 and the stripping chemical solution circulation system 7, the stripping pool 3 is connected with the stripping chemical solution circulation system 7, the stripping chemical solution 6 will be in the stripping pool 3 and the stripping chemical solution circulation system 7 in the deplating process Circular supply and recovery can be realized between the two bases. The base 10 is installed in the deplating pool 3 in a height-adjustable manner. A plurality of semi-finished tubes 1 are vertically placed on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com