Handmade carpet weft compacting iron comb engine driven device and weft compacting method

A motorized device, iron comb technology, applied in carpets, knotting, textiles and papermaking, etc., can solve the problems affecting the overall effect and quality of carpets, different proficiency of weavers, inconsistent carpet density, etc., to improve aesthetics and quality. , The effect of high beat accuracy and high shooting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

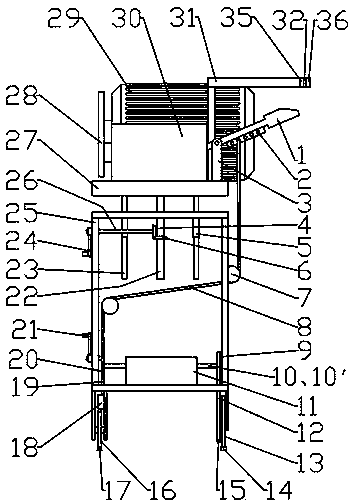

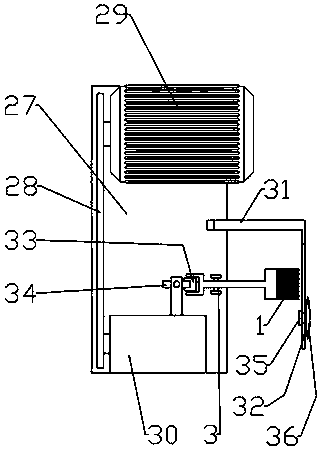

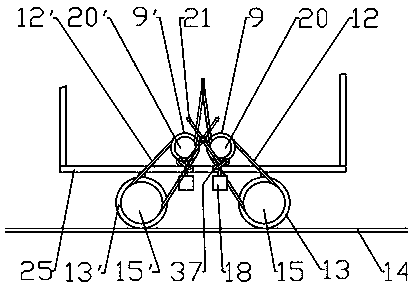

[0014] figure 1 , figure 2 , image 3 As shown, the present invention comprises a frame (25) and an iron comb workbench (27) arranged on the top of the frame (25) and a walking device below, and the iron comb workbench (27) and the frame (25) pass through a lifting mechanism Movably connected, the iron comb workbench (27) is connected with the traveling device through the transmission device, and the traveling device supports the frame (25) to walk.

[0015] Said elevating mechanism comprises multiple positioning rods (23) and screw mandrel (22), driven bevel gear (6), driving bevel gear (4), main shaft (26), rocking handle (24), multiple positioning rods ( 23) One end is fixed under the iron comb workbench (25), the other end is a free end, the free end passes through the sleeve (5) fixed on the frame (25), and the iron comb workbench is positioned by the positioning rod (23) (27) Lift up and down correctly on the frame (25); one end of the screw rod (22) is fixed under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com