Segmental manufacturing and assembling method of large-scale steel pipe trusses with variable cross-section curved beams

A steel pipe truss and variable cross-section technology, applied in the processing of arch beams, bridge door beams, building materials, etc., can solve the problems of difficult spatial position matching, difficult to guarantee design accuracy, long construction period, etc., and shorten the construction period. , Design accuracy assurance, the effect of reducing production errors and hoisting errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

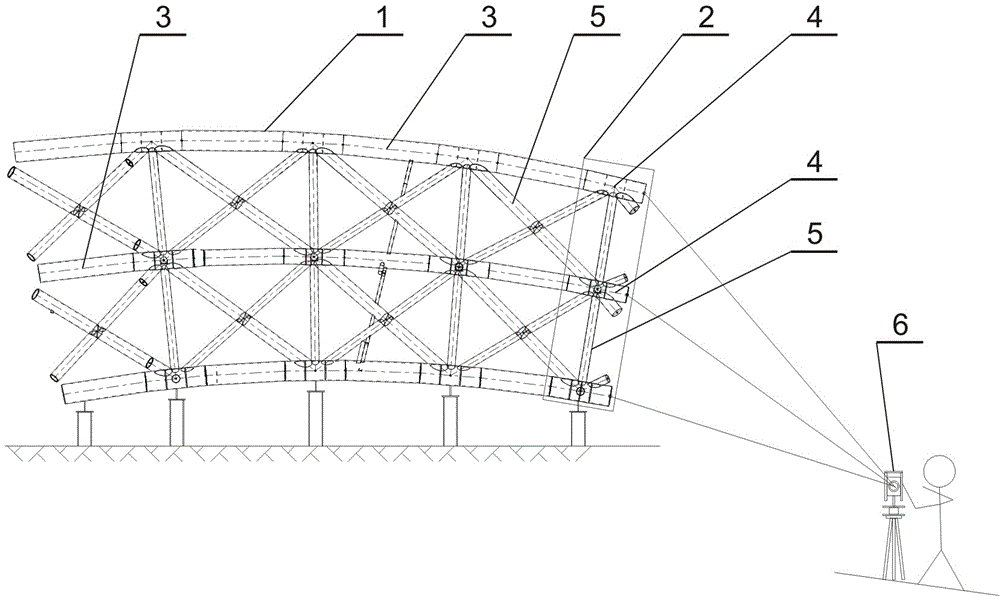

[0023] Taking the city landmark building "The Ring of Life" as an example, the manufacturing and assembling method of the present invention is further described as follows:

[0024] Project Overview

[0025] Project name: city landmark building "Ring of Life";

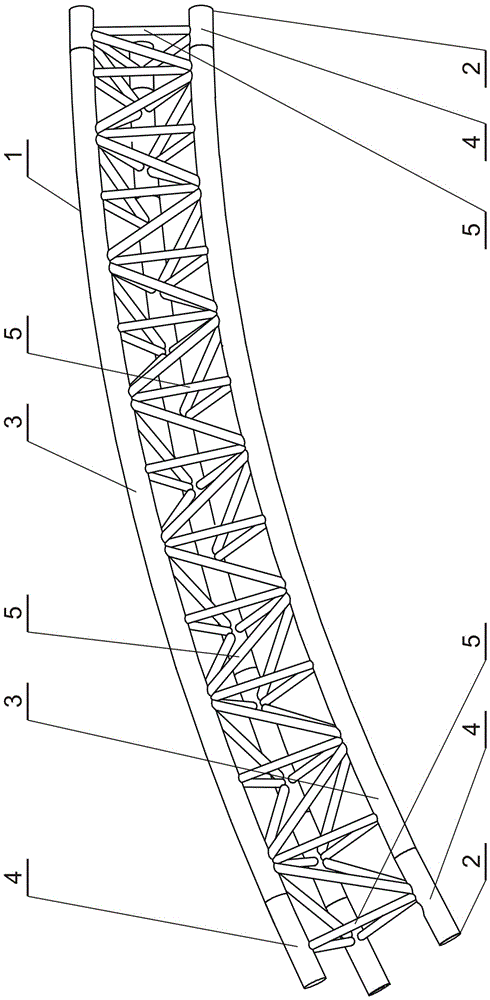

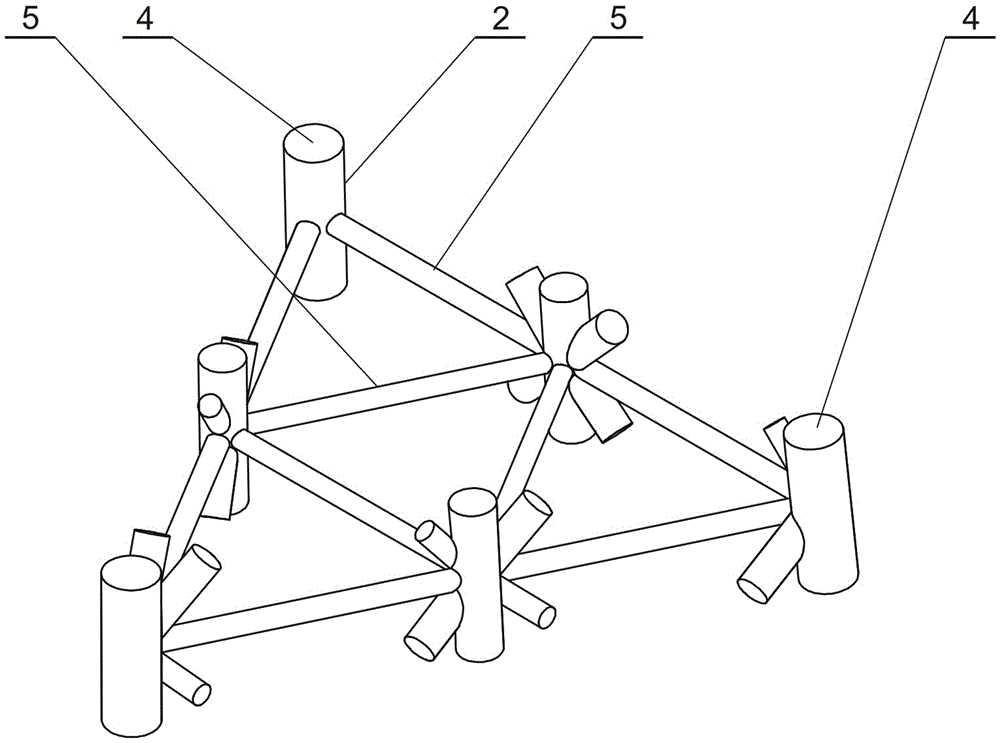

[0026] Structural features: a ring-shaped variable-section curved beam structure composed of large steel pipe trusses, each chord of the curved beam is composed of steel pipes, the corresponding chord on each segment of the curved beam is a curved beam, and the normal direction of each segment on the curved beam The section is a variable section, and the three chords on the section are distributed in a triangle;

[0027] Maximum diameter of the building: Ф175m; Height: 205m;

[0028] Diameter of chord steel pipe: Ф700~1000mm, wall thickness: 18~50mm;

[0029] Diameter of web steel pipe: Ф400~700mm, wall thickness: 12~25mm;

[0030] Production process

[0031] a) The selection of the segment of the curved beam and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com