Assembly method of modularized combined thermal insulation curtain wall panels

An assembly method and combined technology, which is applied in the processing of walls, building materials, building components, etc., can solve the problems of high price, heavy quality of exterior wall curtain wall panels, and difficult on-site construction, so as to reduce damage and meet fire protection requirements , the effect of eliminating the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

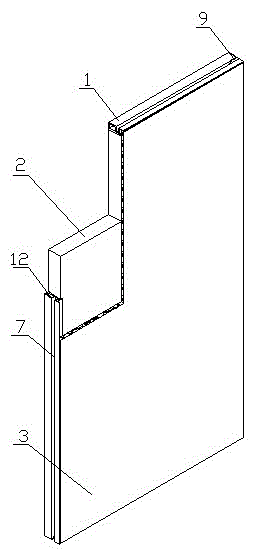

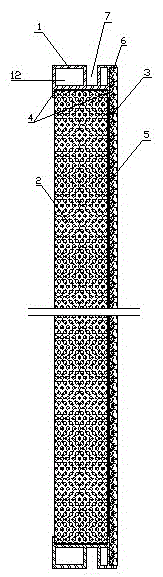

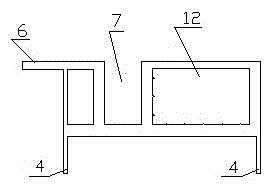

[0045]The assembly method of the modular combined thermal insulation curtain wall panel, the specific steps are as follows: place the base plate 2 flat on a standard horizontal workbench, and apply adhesive between the inner two clip strips 4 of the four aluminum profile sides constituting the aluminum alloy frame 1 5; Then insert the four end faces of the substrate 2 into the two clips 4 on the inner side of the aluminum profile side respectively. The two ends of the aluminum profile side are 45° beveled edges, and the adjacent aluminum profile sides are connected with 45° beveled edges to form an aluminum alloy frame 1. The corner of the aluminum alloy frame 1 is 90°; put the substrate 2 inlaid with the aluminum frame into the tooling frame, and adjust the geometric size; evenly lay high-strength mortar on the upper surface of the substrate 2 inside the aluminum profile rib 6, and use it along the rib 6 Scrape the mortar flat on the reference plane, and then pull the mortar s...

Embodiment 2

[0047] The assembly method of the modular combined thermal insulation curtain wall panel, the specific steps are as follows: place the base plate 2 flat on a standard horizontal workbench, and apply adhesive between the inner two clip strips 4 of the four aluminum profile sides constituting the aluminum alloy frame 1 5; Then insert the four end faces of the substrate 2 into the two clips 4 on the inner side of the aluminum profile side respectively. The two ends of the aluminum profile side are 45° beveled edges, and the adjacent aluminum profile sides are connected with 45° beveled edges to form an aluminum alloy frame 1. The corner of the aluminum alloy frame 1 is 90°; put the substrate 2 inlaid with the aluminum frame into the tooling frame, and adjust the geometric size; evenly lay high-strength mortar on the upper surface of the substrate 2 inside the aluminum profile rib 6, and use it along the rib 6 Scrape the mortar flat on the reference plane, and then pull the mortar ...

Embodiment 3

[0049] The modular combined thermal insulation curtain wall panel assembled by the above method includes an aluminum alloy frame 1, a base plate 2 and a panel 3, at least two clips 4 are arranged inside the aluminum alloy frame 1, and the end surface of the base plate 2 is embedded in the two clips 4, and is attached to the inner side of the aluminum alloy frame 1, and the panel 3 and the substrate 2 are bonded with an adhesive 5; the upper outer edge of the aluminum alloy frame 1 is provided with a rib 6, and the panel 3 is embedded in aluminum Between the ribs 6 of the alloy frame 1, the outer side of the aluminum alloy frame 1 is provided with a buckle groove 7, the buckle groove 7 is embedded with a connecting fastener 8, and the buckle groove 7 on the adjacent side of the aluminum alloy frame 1 is embedded with the same The fastening lock piece 9 realizes the mechanical interlocking of adjacent sides of the aluminum alloy frame 1 .

[0050] The present invention proposes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com