Hydraulic support remote control system based on EtherCAT

A technology of remote control system and hydraulic support, applied in mine roof support, mining equipment, earthwork drilling, etc., can solve the problems of hydraulic support unable to maintain real-time performance, increasing the complexity of system development, and inability to guarantee real-time performance. , to achieve the effect of simple and reliable design, reducing complexity and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below in conjunction with the accompanying drawings.

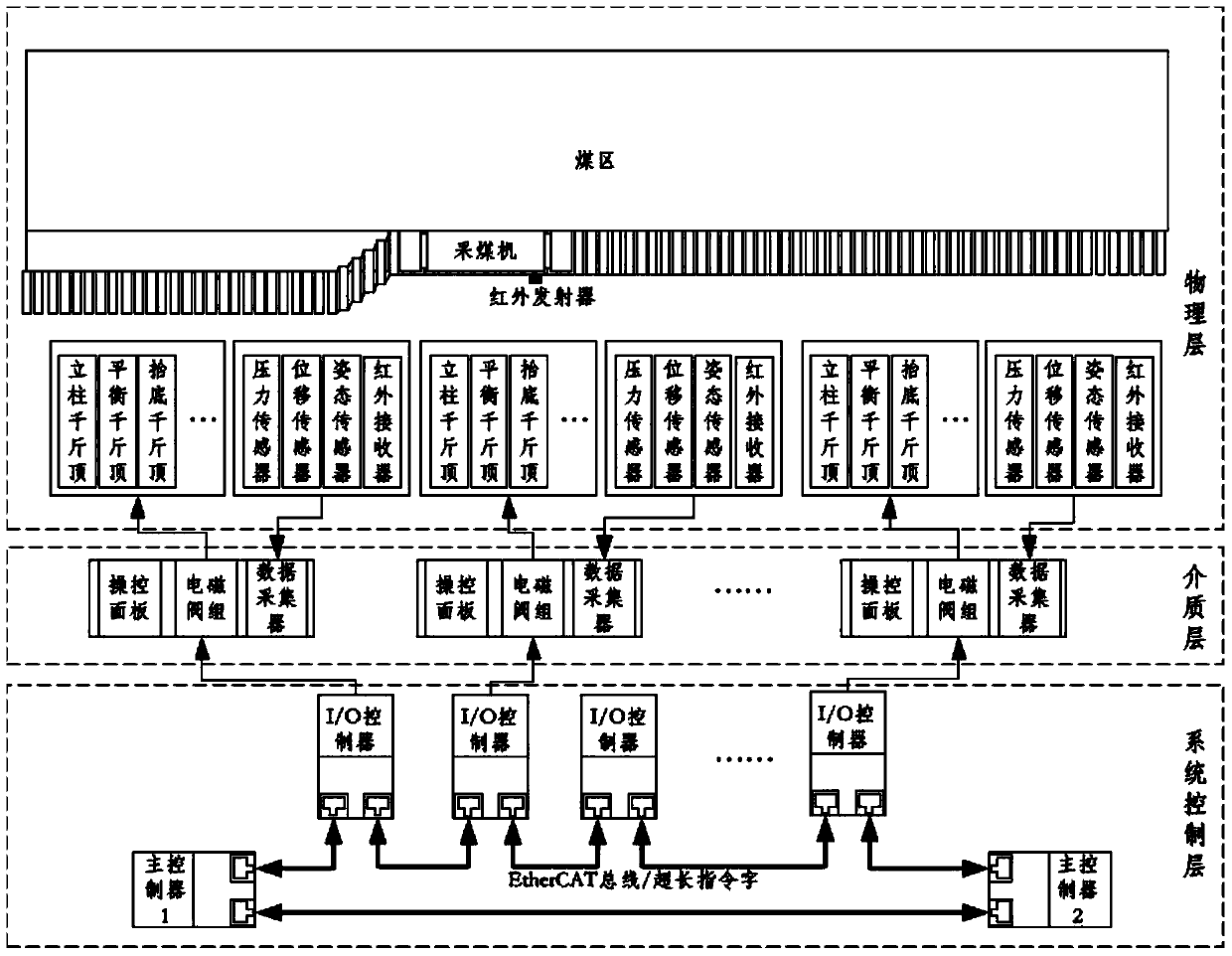

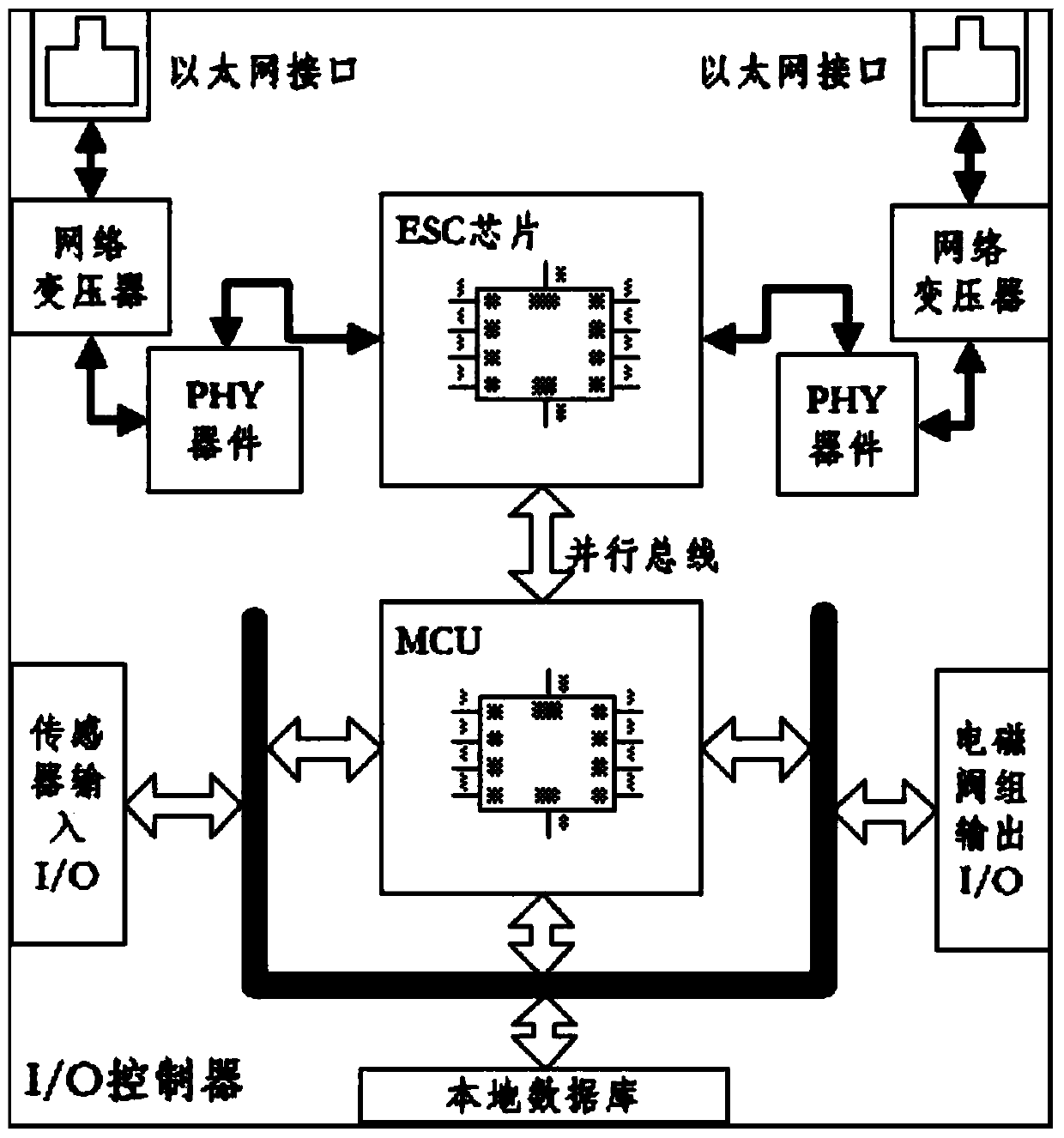

[0023] like figure 1 and figure 2 As shown, a remote control system for hydraulic supports based on EtherCAT includes a physical layer, a medium layer and a system control layer, and they are connected in sequence. The physical layer includes the shearer, hydraulic supports and For scraper conveyors, the hydraulic support is provided with several hydraulic cylinders, and the main power of its action comes from the above-mentioned hydraulic cylinders, specifically: column hydraulic cylinder, balance hydraulic cylinder, base lifting hydraulic cylinder, side protection hydraulic cylinder , side guard hydraulic cylinders, telescopic beam hydraulic cylinders, tail beam hydraulic cylinders, etc., on the specific hydraulic supports, there are mainly column jacks, balance jacks and bottom lifting jacks, etc., and sensors, such as pressure sensors, displacement sensors and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com