Integral multiway valve with integral hydraulic locks and fouling resistant plug-in mounting overflow valve

An integral, hydraulic lock technology, applied in the field of multi-way valves, can solve problems such as internal leakage, poor sealing, and affecting the reliability of multi-way valves, so as to avoid internal leakage, reduce processing costs, and reduce inter-chip leakage Effects of oil risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

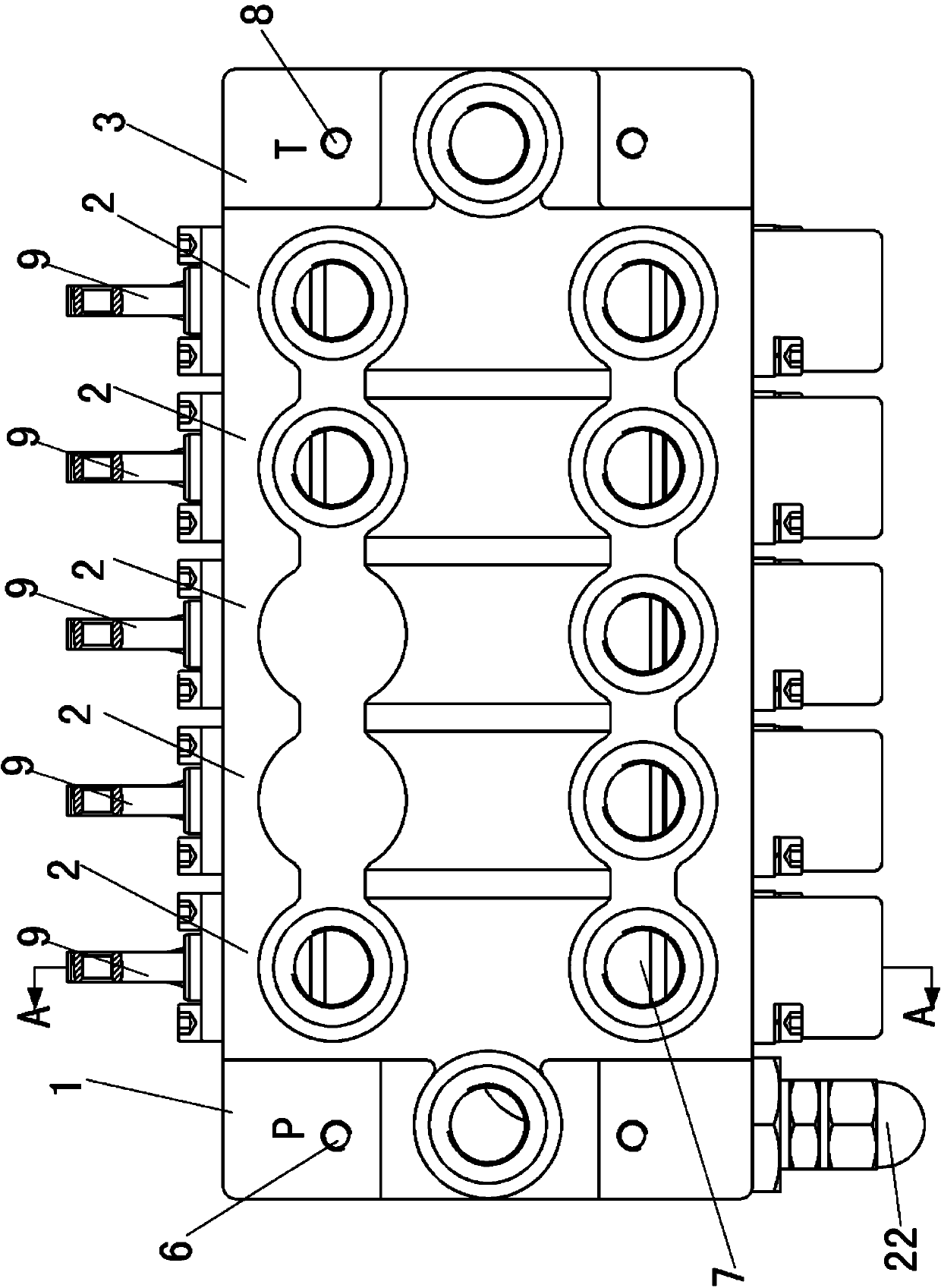

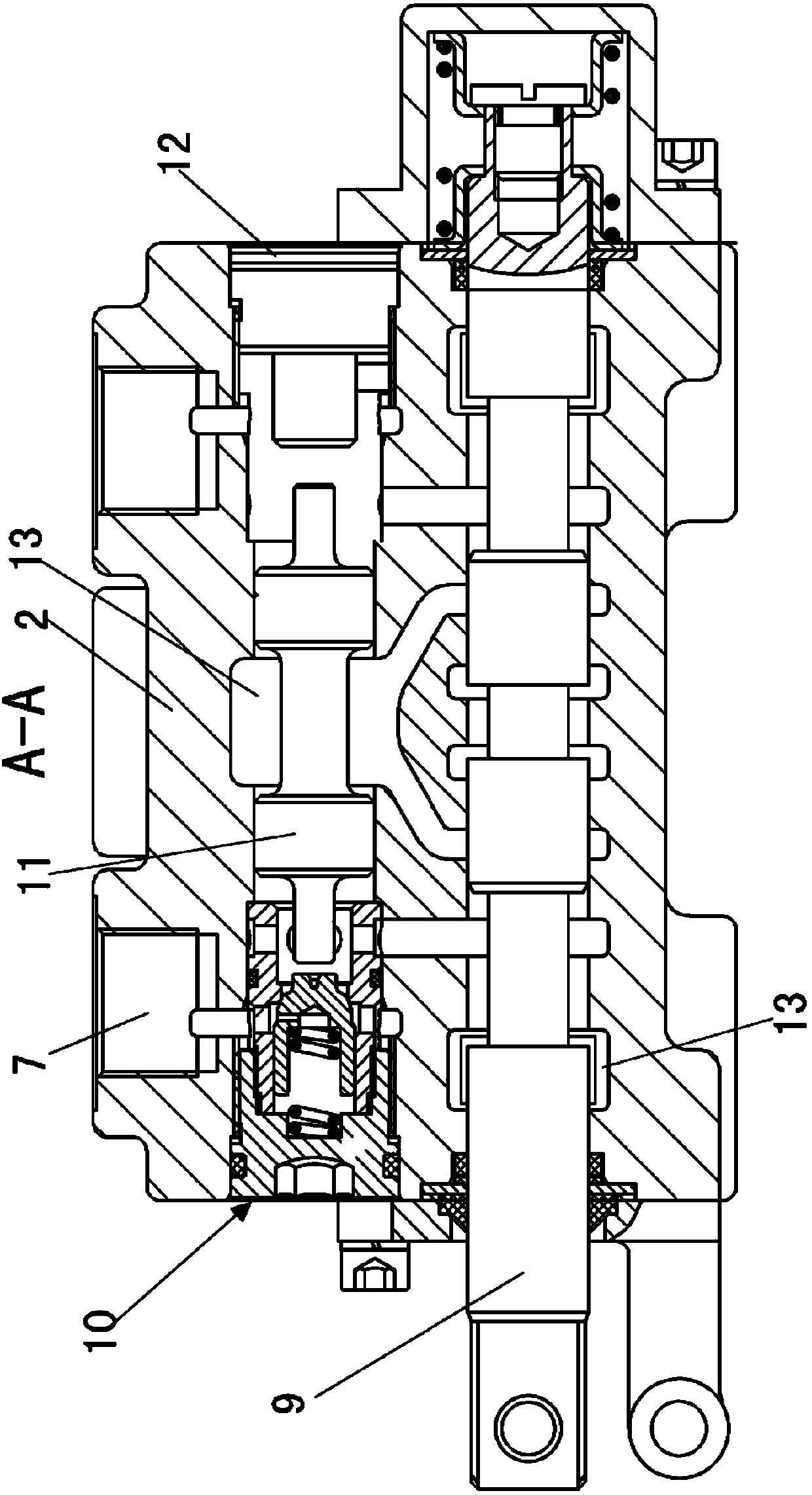

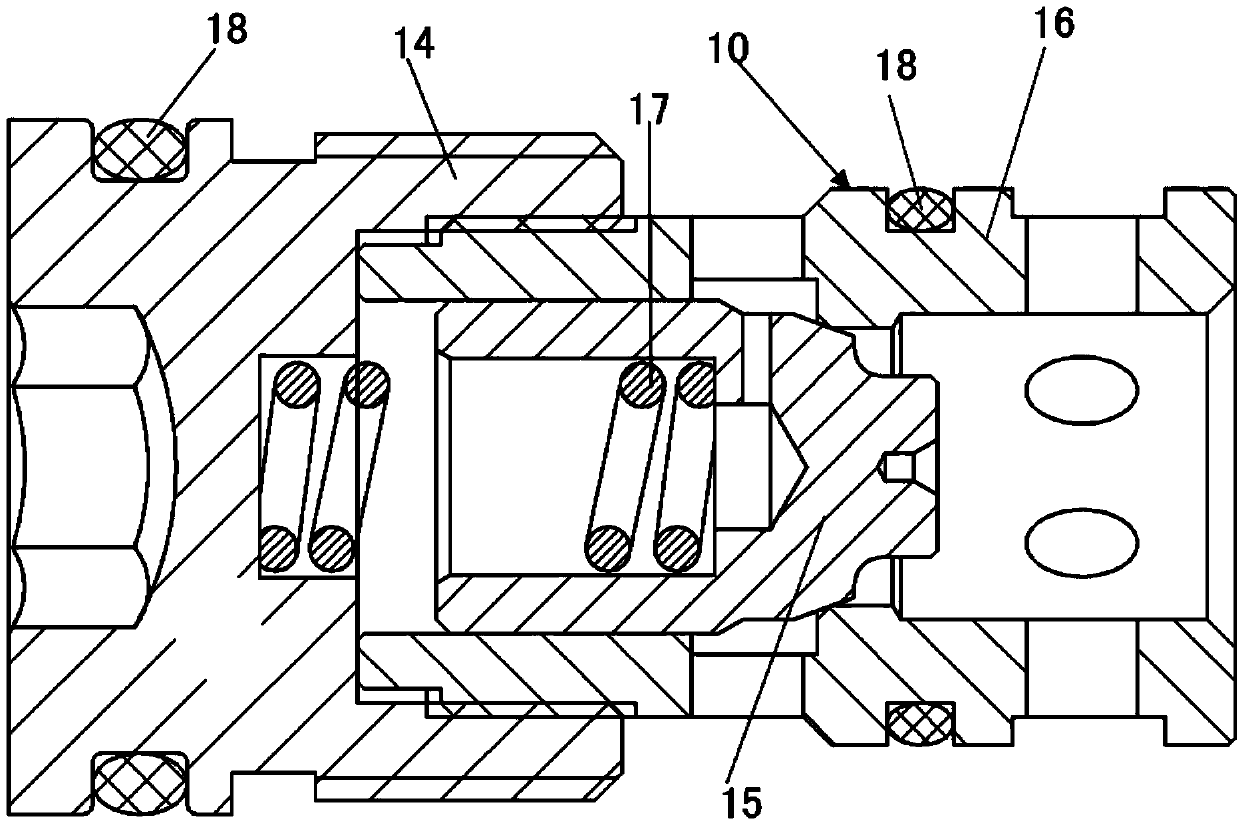

[0033] See attached Figure 1-6 , the integral multi-way valve provided with integral hydraulic lock and pollution-resistant plug-in overflow valve of the present invention includes an oil inlet valve slice 1, a plurality of working valve slices 2 and an oil return valve slice 3; Multiple working valve slices 2 are arranged between the oil inlet valve slice 1 and the oil return valve slice 3; the oil inlet valve slice 1, the multiple working valve slices 2 and the oil return valve slice 3 are integral structures ; The oil inlet valve plate 1 is provided with an oil inlet port P6, and the oil return valve plate 3 is provided with an oil return port T8; each of the plurality of working valve plates 2 is provided with a or two working oil ports 7; a valve stem 9 is inserted into each working valve piece 2 of the plurality of working valve pieces 2, and one end of the valve stem 9 protrudes outside the working valve piece 2 ;

[0034] The working valve piece 2 shown is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com