Electronic Control System of Vehicle Parallel Planetary Gear Transmission

A planetary gear train, electronic control system technology, applied in the direction of elements with teeth, transmission control, belt/chain/gear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

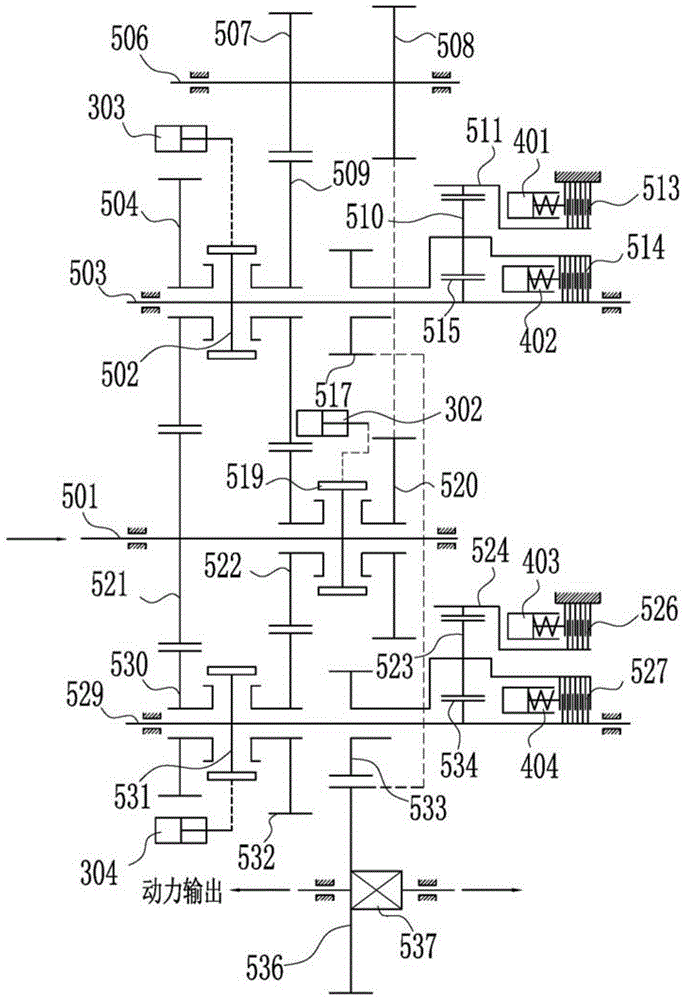

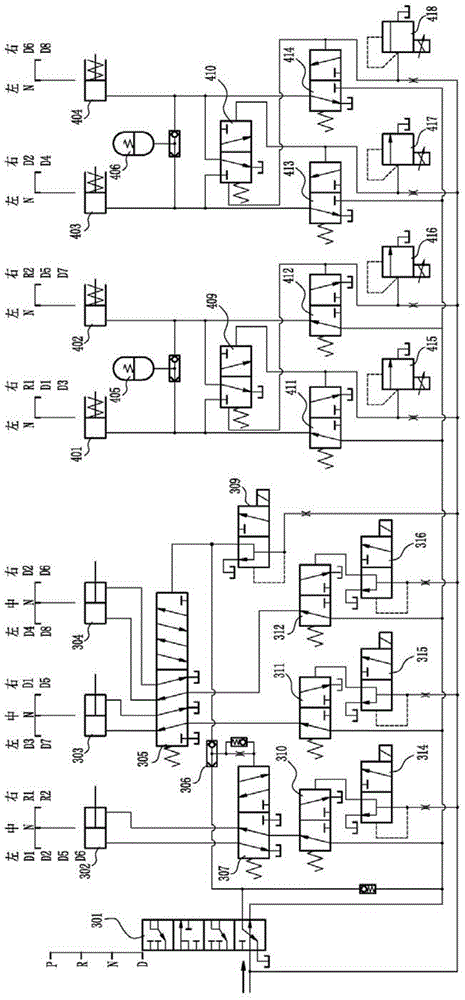

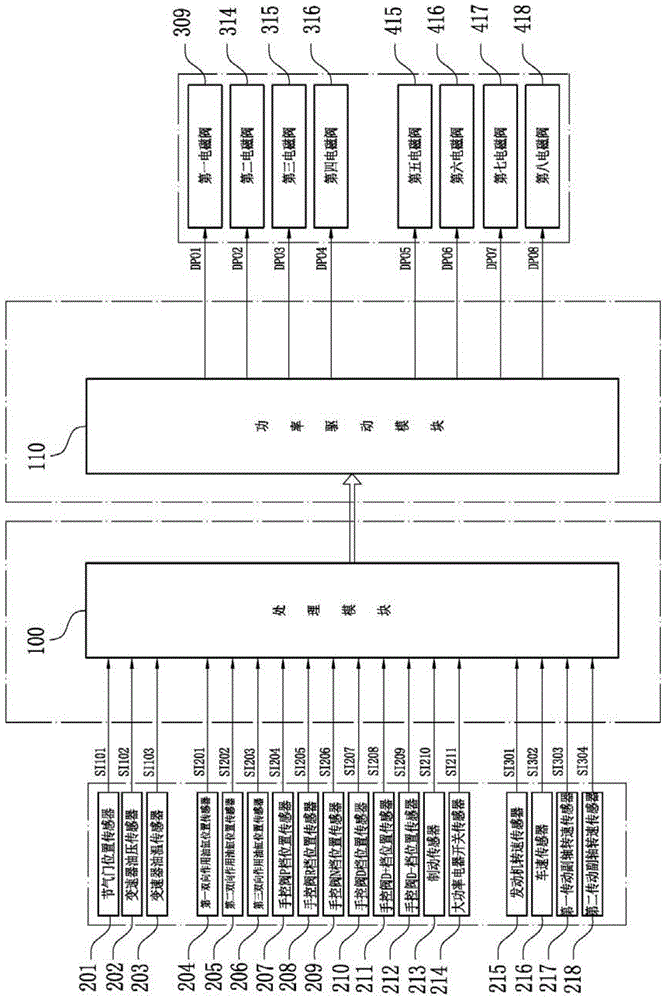

[0071] like Figure 1-3 As shown, an electronic control system for a vehicle parallel planetary gear train transmission includes a processing module 100 and a power drive module 110. The processing module 100 receives a throttle opening sensor 201, a transmission oil pressure sensor 202, a transmission oil temperature Sensor 203, brake sensor 213, high-power electrical switch sensor 214, engine speed sensor 215, vehicle speed sensor 216, first transmission countershaft speed sensor 217 for detecting the speed of the first intermediate shaft 503, for detecting the second intermediate shaft The signal output by the second transmission countershaft speed sensor 218 with a speed of 529, the double-acting oil cylinder position sensor and the manual valve position sensor, and the signal is logically analyzed and processed to form a control signal and output to the power drive module 110. The power drive module 110 Under the control of the control signal, output driving electric ener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com