Electric air door sheet of refrigerator

An electric damper, door panel technology, applied in the direction of door leaf, lighting and heating equipment, cooling fluid circulation device, etc., can solve the problems of high cost, difficult assembly, and difficult processing, and achieve the effect of convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

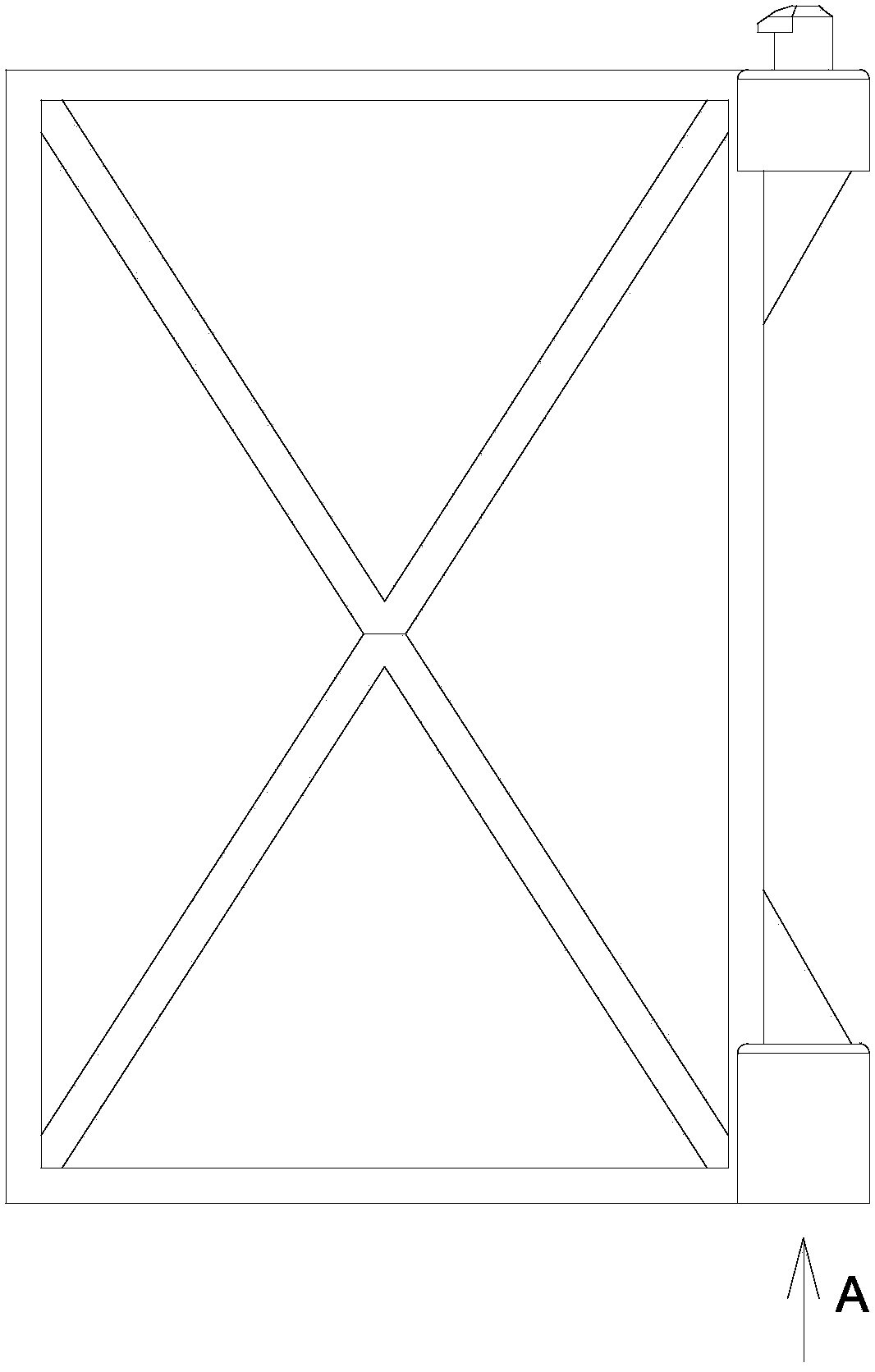

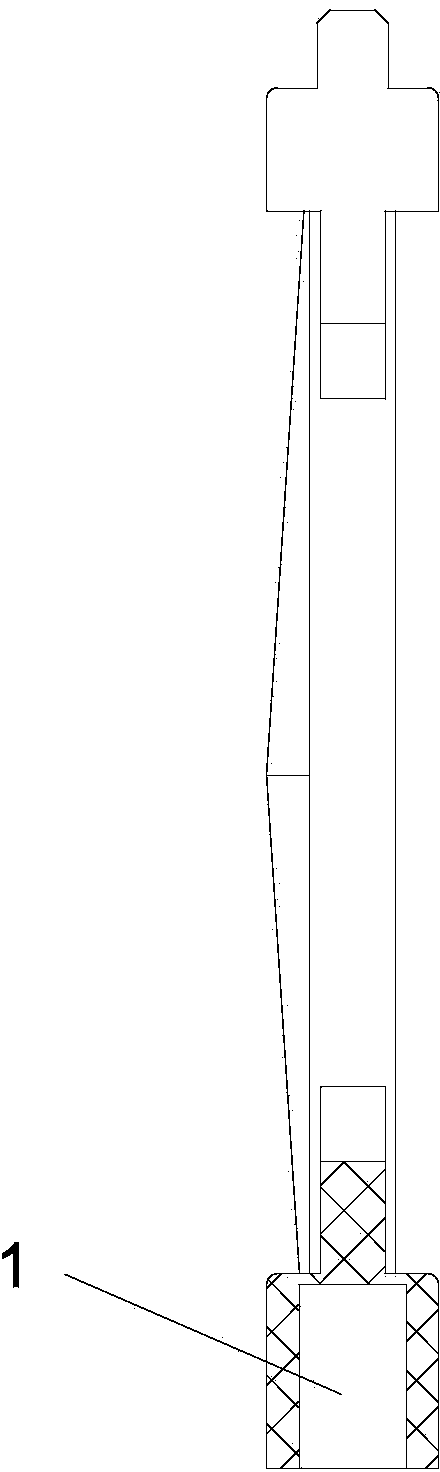

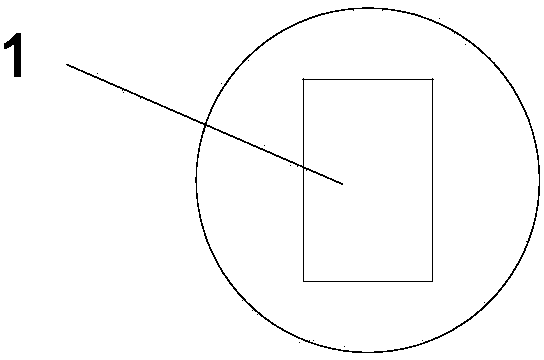

[0017] as attached figure 1 , 4 Shown is an electric damper door panel of a refrigerator. A connecting hole 1 is provided at the connecting part of the rotating shaft on the door panel, and sawtooth 2 is provided on the contact part between the connecting hole 1 and the rotating shaft, that is, the inner wall of the connecting hole 1 is provided with sawtooth 2 . The tooth height of the sawtooth 2 is 0.6mm±0.1mm, the tooth spacing is 0.4mm±0.1mm, and the tooth shape is pointed or round.

[0018] Specifically, as attached Figure 4 As shown, the serrations 2 are arranged on the upper edge of the inner wall of the connecting hole 1, arranged linearly, and are arranged on at least one upper edge of one side.

[0019] When the rotating shaft is inserted into the connecting hole, the sawtooth acts on the surface of the rotating shaft, making the plastic part of the rotating shaft easy to deform. At the same time, the sawtooth and the surface of the rotating shaft form a transiti...

Embodiment 2

[0022] The difference from Embodiment 1 is that the serrations 2 are arranged in the inner wall of the connecting hole 1 in a linear arrangement.

Embodiment 3

[0024] The difference from Embodiment 1 is that the sawtooth 2 is arranged in the inner wall of the connection hole 1 , scattered and arranged in a planar manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com