Fiber grating displacement meter based on spring and constant strength beam

A technology of equal-strength beams and fiber gratings, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of low measurement accuracy and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

[0022] The present invention will be further described below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, but are only examples to make the advantages of the present invention more clear and easy to understand.

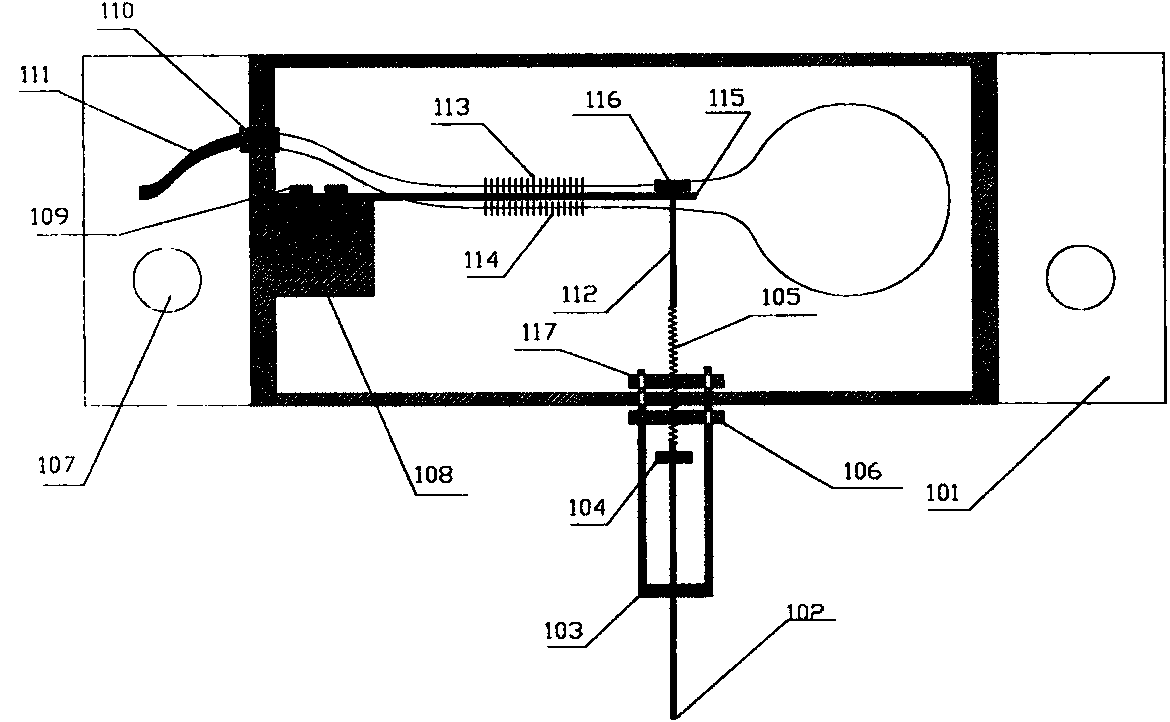

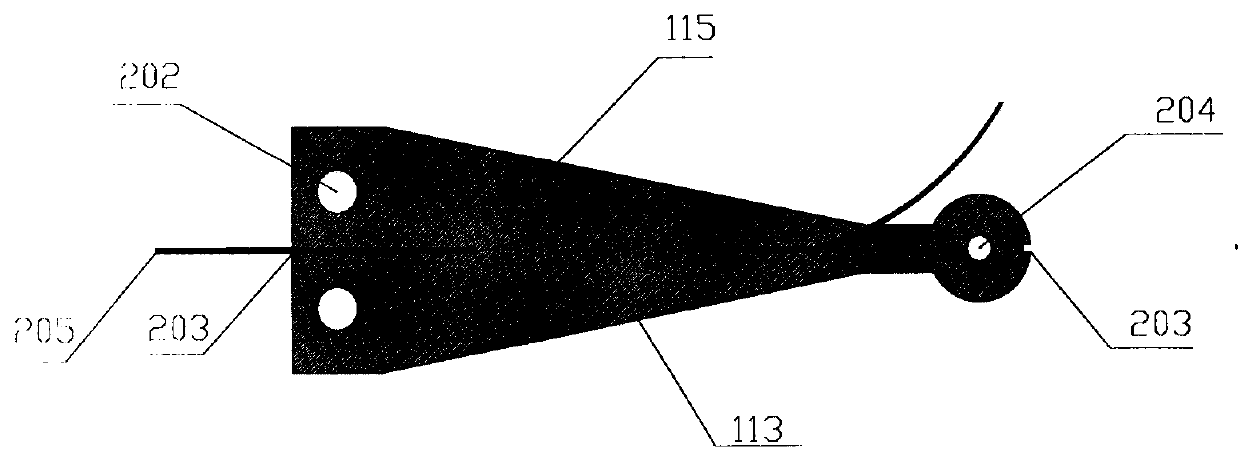

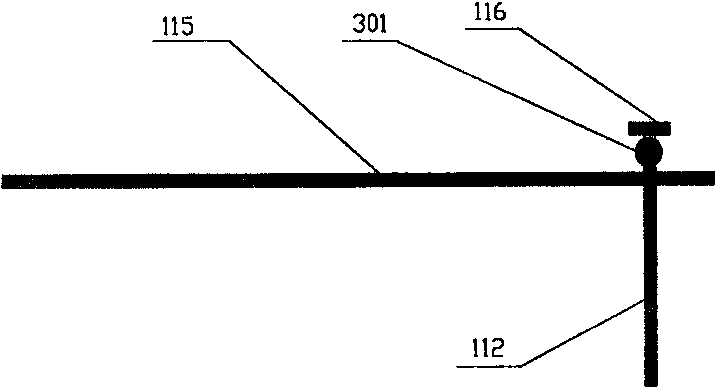

[0023] Such as figure 1 , figure 2 with image 3 As shown, the tail end of the equal-strength beam 115 is fixed to the housing 101 through the equal-strength beam fixing base 108 by using the equal-strength beam fixing screws 109, and the fiber gratings 113 and 114 pasted on the front and back sides of the equal-strength beam 115 pass through the housing 101 The armored optical cable 111 is introduced, and the armored optical cable 111 is fixed to the casing 101 by the cable sealing interface 110 to protect the optical fiber 205; There is a hollow steel ball 301 between the protrusions 116 of 115, the other end of the inner wire rope 112 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com