A device and method for measuring the impedance angle of an ultrasonic transducer by an orthogonal correlation method

A technology of ultrasonic transducers and measuring transducers, which is applied in the direction of measuring devices, measuring electrical variables, phase angles between voltage and current, etc., which can solve periodic errors, unsatisfactory performance of hardware equipment, and slow frequency of measured signals Fluctuation and other problems, to achieve high accuracy, small amount of calculation, high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

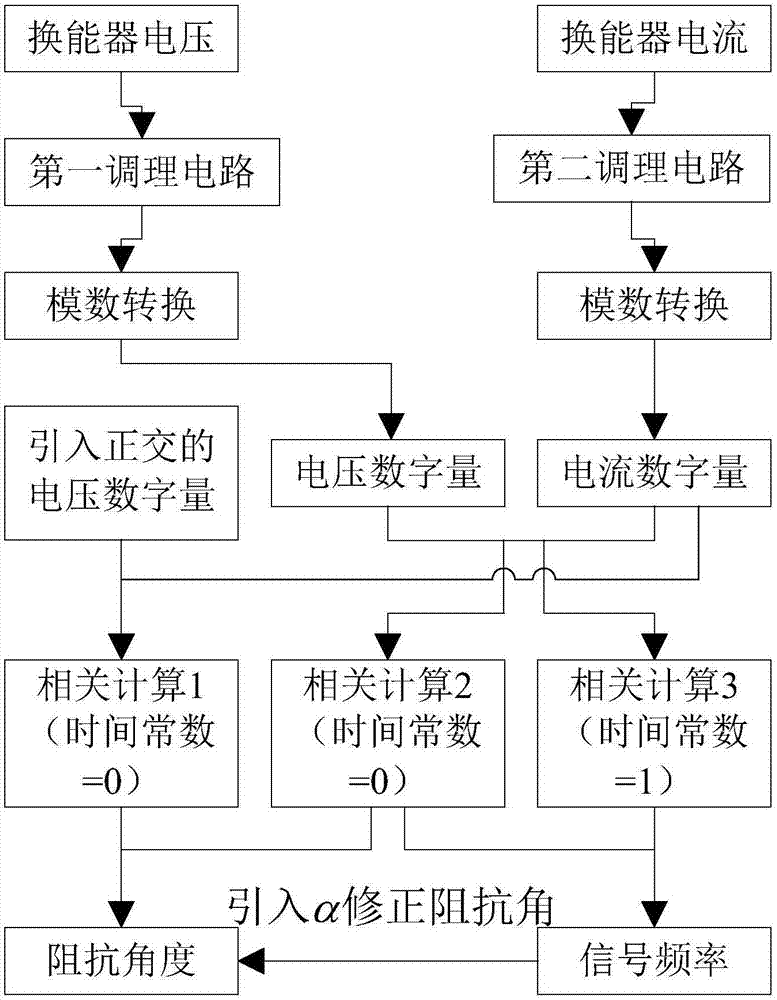

Method used

Image

Examples

Embodiment Construction

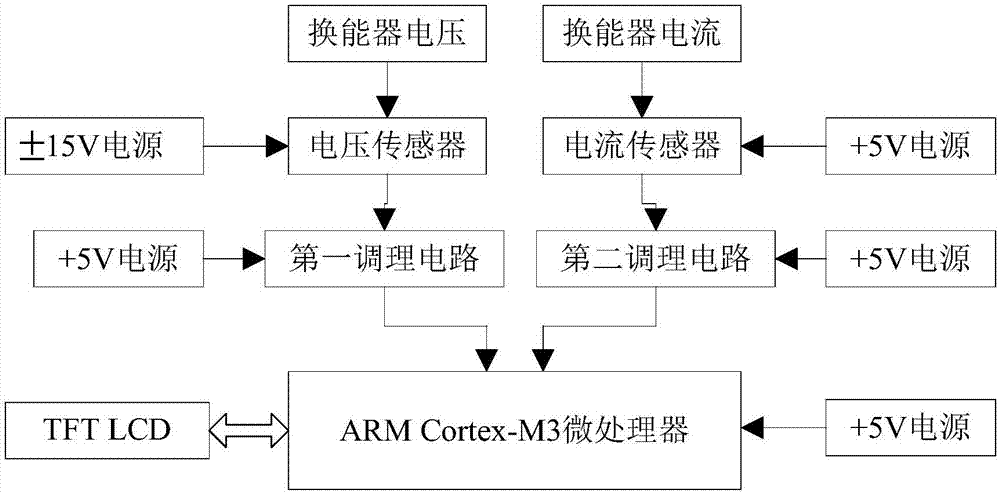

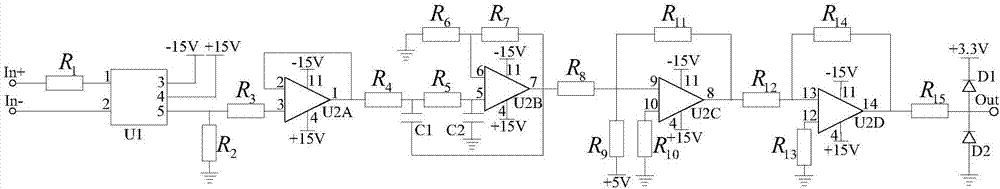

[0051] Such as figure 2 , image 3 , Figure 4 As shown, a device for measuring the impedance angle of an ultrasonic transducer by the orthogonal correlation method, the device includes a voltage sensor for measuring the voltage of the transducer, a current sensor for measuring the current of the transducer, a first conditioning circuit, a second conditioning circuit, ARM Cortex-M3 microprocessor and TFT-LCD display unit;

[0052] The voltage sensor is connected to the signal input interface of the first conditioning circuit through a Dupont line, and the current sensor is connected to the second conditioning circuit through a Dupont line; the signal output interface of the first conditioning circuit is connected to a module inside the ARM Cortex-M3 microprocessor through a Dupont line. Connect to the input port of the digital converter; the signal output interface of the second conditioning circuit is connected to another analog-to-digital converter input port inside the A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com