Welding pad structure and display device

A display device and welding pad technology, which is applied to static indicators, instruments, electrical components, etc., can solve problems such as poor flatness of the welding pad structure, influence on signal transmission, abnormal ACF, etc., and achieve the effect of improving uneven contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manners of the pad structure and the display device provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

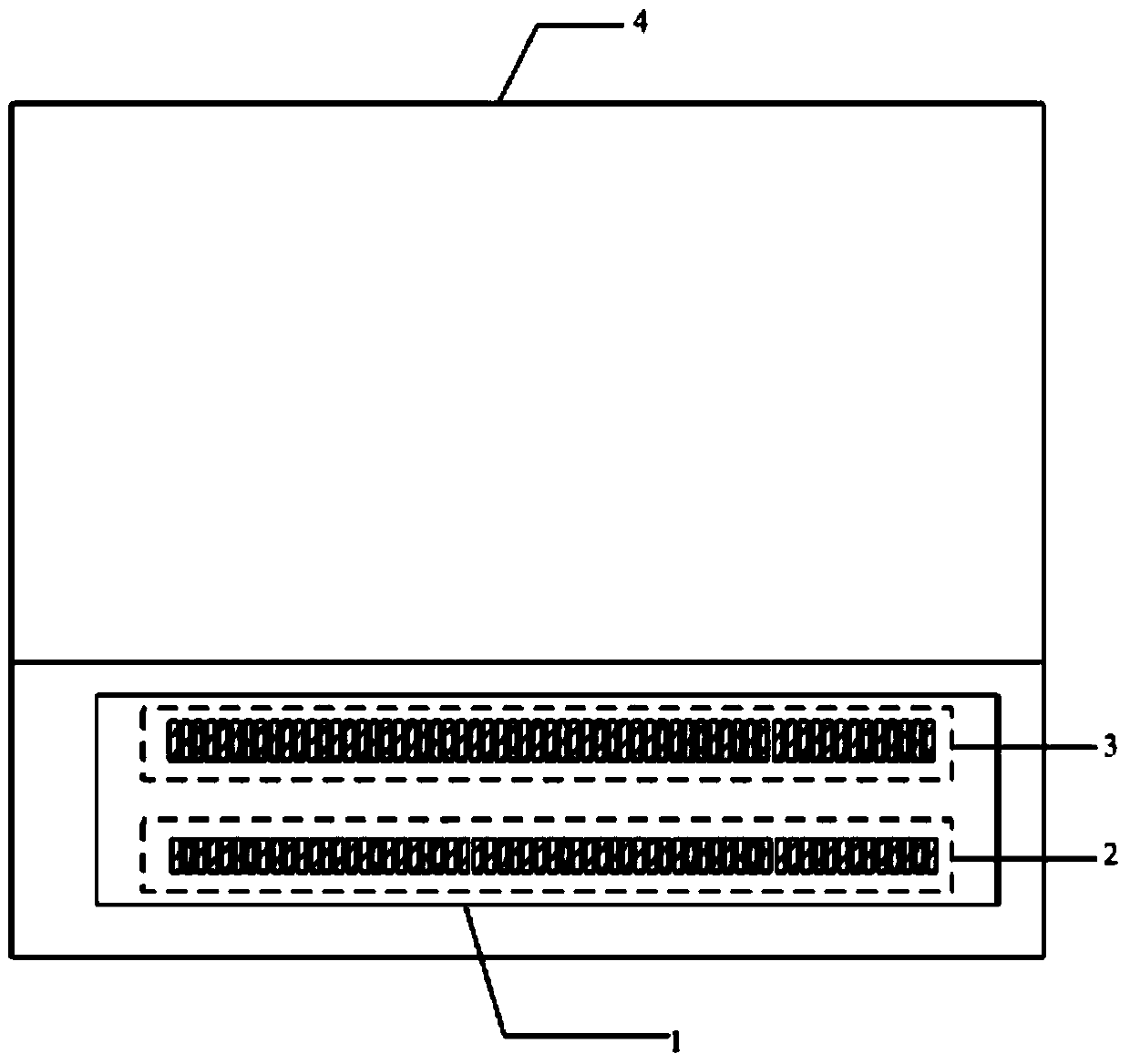

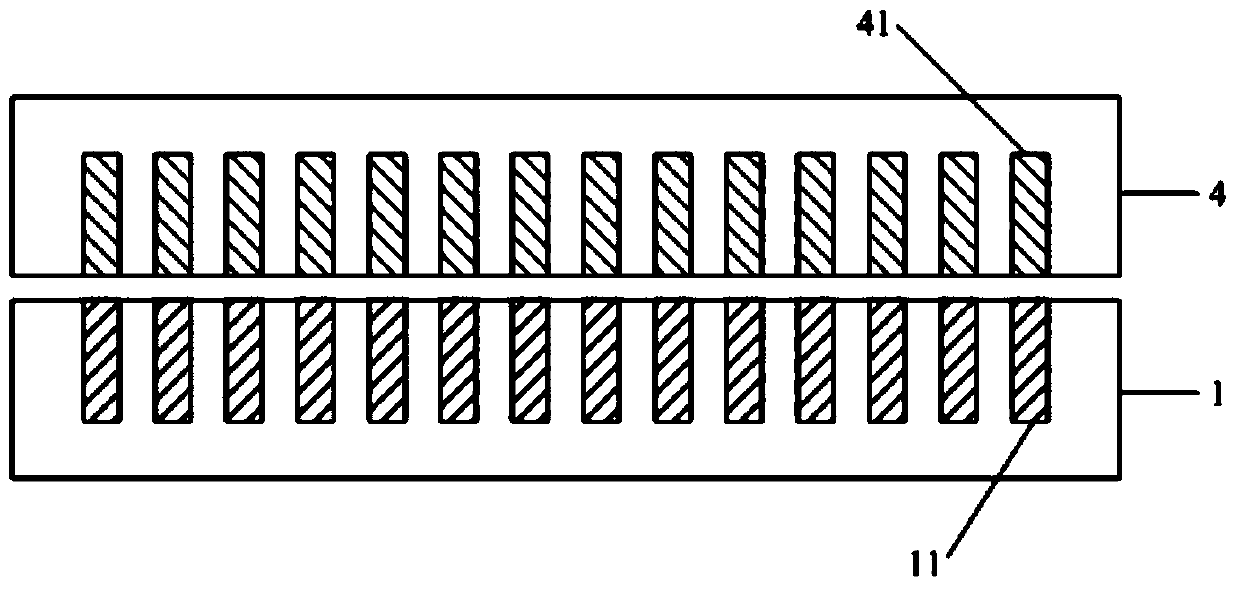

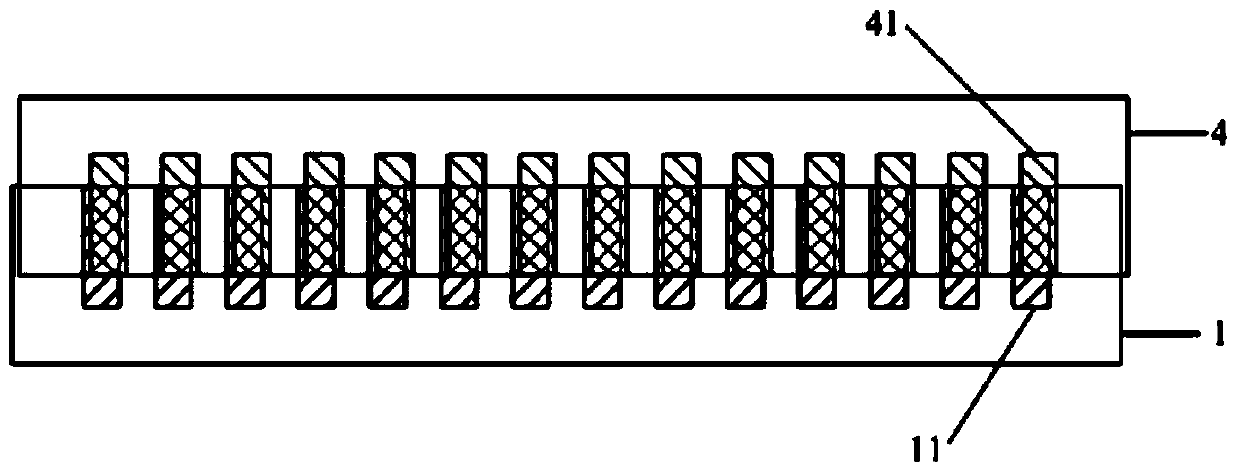

[0040] A pad structure provided by an embodiment of the present invention, such as image 3 As shown, it includes a first welding pad unit 100 and a second welding pad unit 200 that are electrically connected by crimping, wherein the first welding pad unit 100 has a plurality of first welding pads 101 arranged side by side, and the second welding pad unit 100 has a plurality of first welding pads 101 arranged side by side. The pad unit has a plurality of second welding pads 201 arranged side by side, and each second welding pad 201 is electrically connected to the corresponding first welding pad 101; the first welding pad unit 100 is divided into at least two welding areas ( image 3 The area surrounded by each dotted line box in the above is a welding area), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com