Numerical control full-servo bending machine

A bending machine and servo motor technology, applied in the direction of punching machines, presses, feeding devices, etc., can solve the problems of unstable movement speed, low precision of bending machines, and decline in product quality, so as to improve precision and work Efficiency, reduced operating hours, improved product quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further understand the features, technical means, specific objectives and functions achieved by the present invention, and to analyze the advantages and spirit of the present invention, a further understanding of the present invention can be obtained through the following detailed description of the present invention in conjunction with the accompanying drawings and specific embodiments.

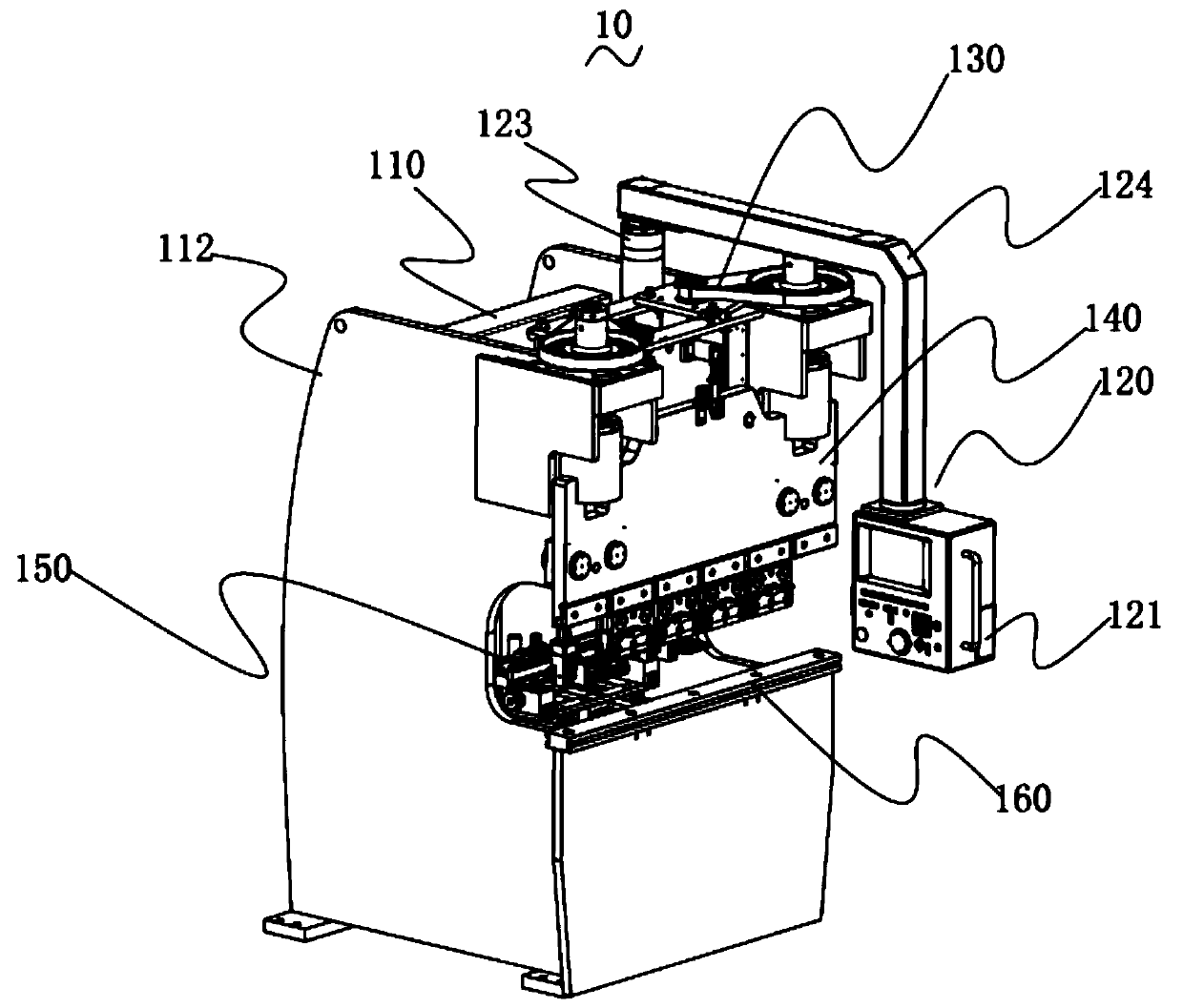

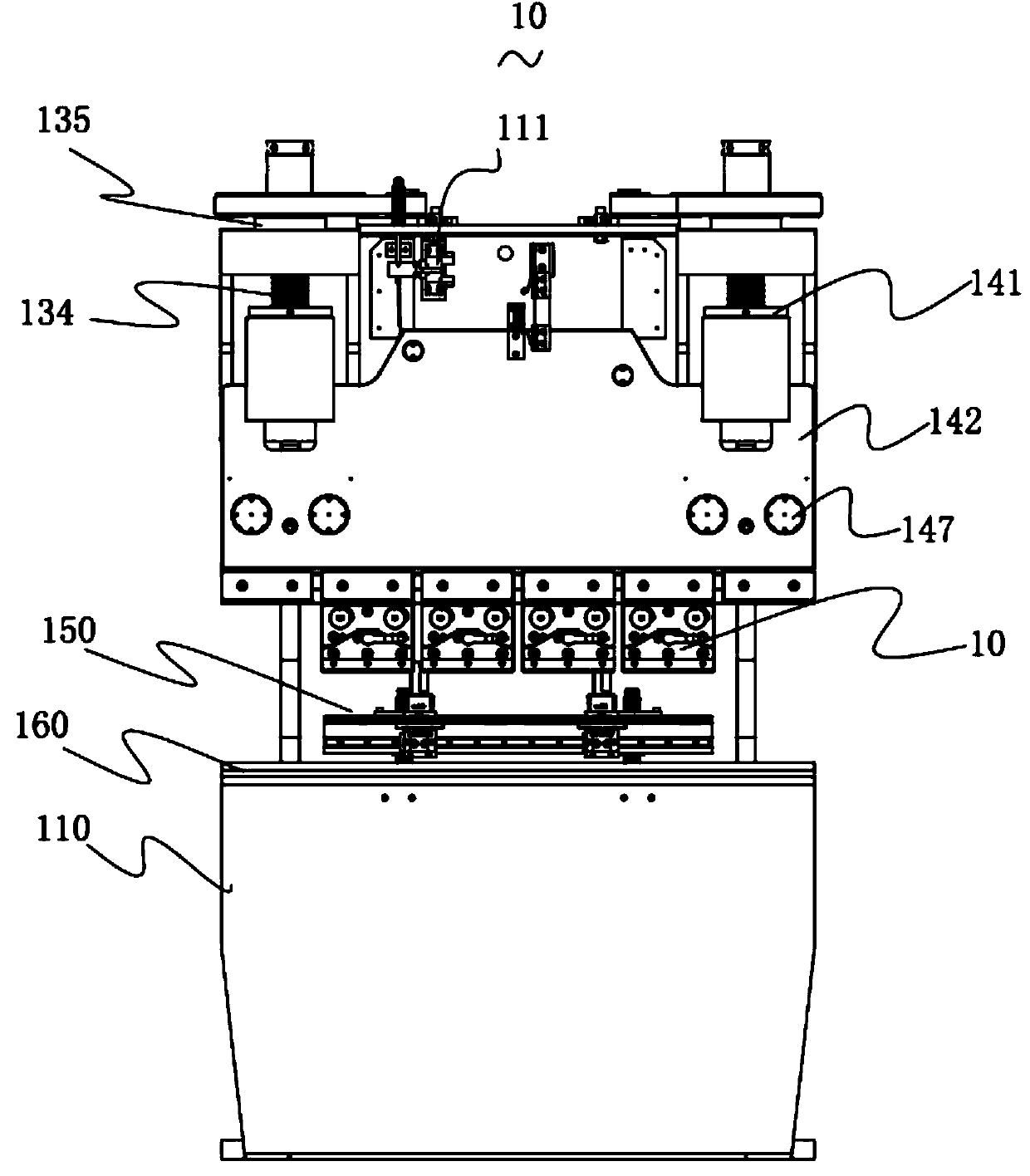

[0036] See attached figure 1 , which is a schematic structural diagram of a CNC full-servo bending machine 10 in an embodiment. Also see attached figure 2 , which is figure 1 The schematic diagram of the structure of the numerically controlled full-servo bending machine 10 without the numerically controlled device 120 is shown.

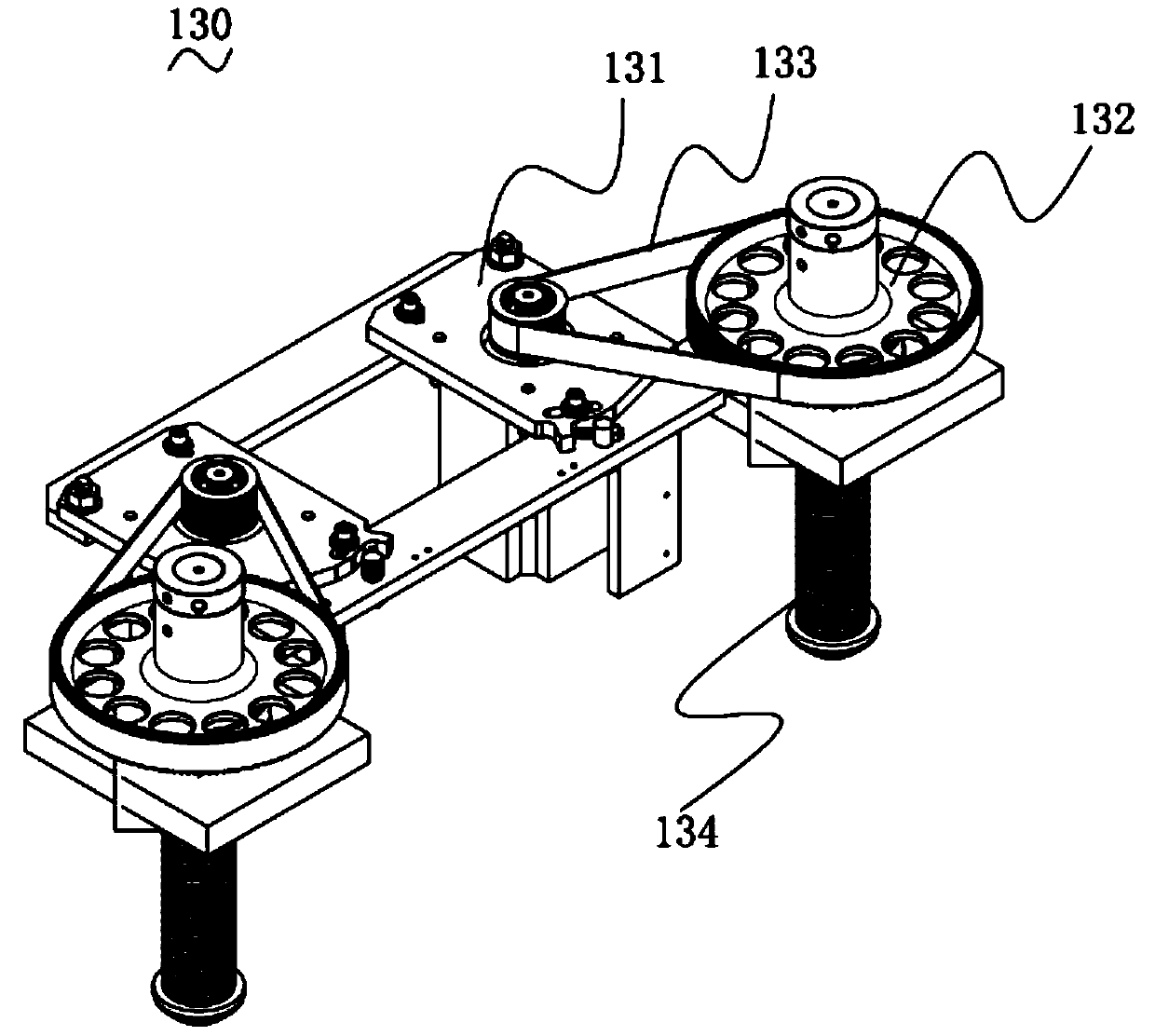

[0037] The numerical control full servo bending machine 10 includes: a frame 110 , a numerical control device 120 , a transmission device 130 installed on the frame 110 , a sliding device 140 , a back gauge device 150 and a workbench 160 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com