A method for removing acidic wastewater fe3+ acidity

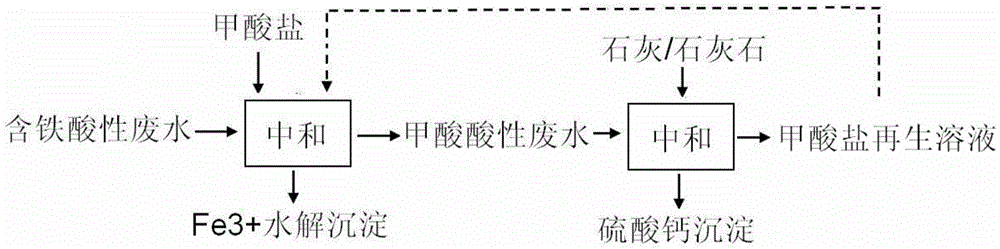

A technology of acid wastewater and acidity, applied in chemical instruments and methods, water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem of inconvenient recycling or safe disposal, low alkalinity utilization efficiency, and poor long-term operation effect. and other problems, to achieve the effect of reducing the difficulty of recycling or safe disposal, easy biochemical removal, and reducing the difficulty of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

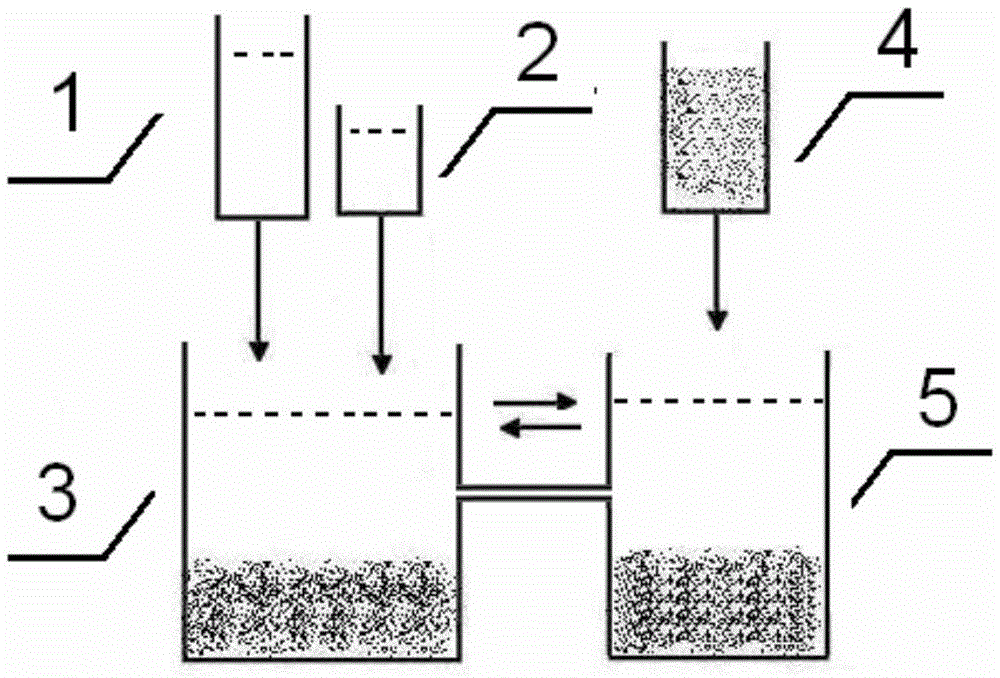

[0027] Processing devices such as figure 2 As shown, the solutions in the acid wastewater pool 1 and the formate concentrated solution pool 2 can enter Fe through the pipelines with valves respectively. 3+ The solution in the hydrolysis sedimentation tank 3 and the lime mud tank 4 can enter the formate solution regeneration tank 5 through a pipeline with a valve, and the Fe 3+ Between the hydrolysis sedimentation tank 3 and the formate brine solution regeneration tank 5, the solution is forwardly or reversely input through a pipeline with a valve as required.

[0028] The concentration of sodium formate in formate concentrate pool 2: 6mol / L.

[0029] Composition of simulated acid wastewater in acid wastewater tank 1: Fe 3+ The acidity is 120mmol / L (equivalent to Fe 3+ Concentration 40mmol / L), H + The acidity is 20mmol / L, the sulfate radical concentration is 86mmol / L, the calcium ion concentration is 6mmol / L, Cu 2+ The concentration is 10mmol / L.

[0030] Sequencing batch...

Embodiment 2

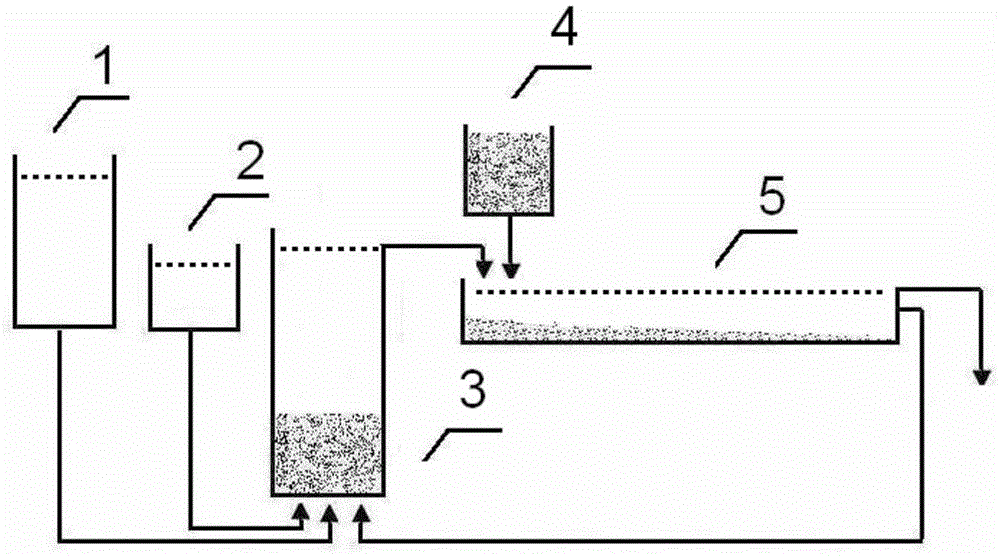

[0034] Processing devices such as image 3 As shown, the outlet of the acid wastewater pool 1 and the outlet of the formate concentrated solution pool 2 pass through the pipeline and the long columnar Fe respectively. 3+ The water inlet at the bottom of the hydrolysis sedimentation tank 3 is connected, Fe 3+ The effluent of the hydrolysis sedimentation tank 3 flows into the left end of the long-trough formate solution regeneration tank 5 through the overflow outlet on the upper part, and the effluent of the limestone mud tank 4 flows into the left end of the formate solution regeneration tank 5 through the outlet at the bottom, and the formic acid The reflux outlet at the right end of the salt solution regeneration tank 5 passes through the pipeline and the Fe 3+ The water inlet at the bottom of the hydrolysis sedimentation tank 3 is connected for returning the formate solution to Fe 3+ The hydrolysis sedimentation tank 3 and the overflow outlet at the upper right end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com