Porous plum blossom tube and its preparation method

A plum-blossom tube and raw material technology, applied in the field of porous plum-blossom tubes and polymer materials, can solve the problem of acid and alkali resistance, salt-alkali resistance, poor corrosion resistance, unreasonable raw material ratio of plum blossom tubes, poor oxidation resistance, and poor aging ability, etc. problems, to achieve the effect of reducing construction difficulties, light weight, high temperature resistance and cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

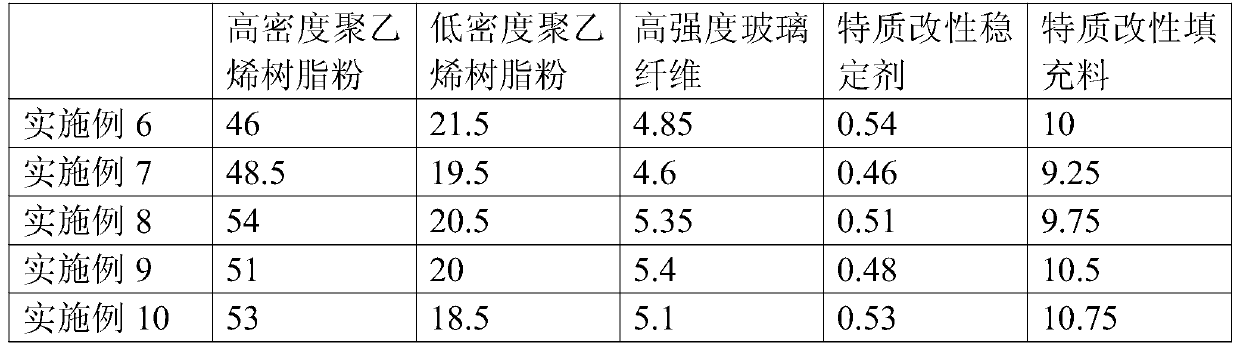

Examples

Embodiment 1

[0041] Porous plum blossom tube, the raw materials are composed of the following materials by weight: 50 parts of high-density polyethylene resin powder, 20 parts of low-density polyethylene resin powder, 5 parts of high-strength glass fiber, 0.5 parts of special modified stabilizer, special modified filler 10 servings.

[0042] The high-density polyethylene resin powder is 5000S high-density polyethylene resin produced by Daqing Petrochemical; the low-density polyethylene resin powder is DFDA-7042 linear low-density polyethylene.

[0043] The special modified stabilizer is a new generation of NX-2007 impact-resistant composite stabilizer produced by Weifang Naixin.

[0044] The high-strength glass fiber is a model CM10106G-45N high-strength glass fiber produced by Toray, Japan.

[0045] Special modified fillers include base material, lubricant and plasticizer; the mass ratio of base material, lubricant and plasticizer is 100:5:3;

[0046] The composition of the base materia...

Embodiment 2

[0060] Porous plum blossom tube, the raw materials are composed of the following materials by weight: 52.5 parts of high-density polyethylene resin powder, 19 parts of low-density polyethylene resin powder, 5.5 parts of high-strength glass fiber, 0.55 parts of special modified stabilizer, special modified filler 9.5 servings.

[0061] The high-density polyethylene resin powder is 5000S high-density polyethylene resin produced by Daqing Petrochemical; the low-density polyethylene resin powder is DFDA-7042 linear low-density polyethylene.

[0062] The special modified stabilizer is a new generation of NX-2007 impact-resistant composite stabilizer produced by Weifang Naixin.

[0063] The high-strength glass fiber is a model CM10106G-45N high-strength glass fiber produced by Toray, Japan.

[0064] Special modified fillers include base material, lubricant and plasticizer; the mass ratio of base material, lubricant and plasticizer is 100:5:3;

[0065] The composition of the base m...

Embodiment 3

[0068] Porous plum blossom tube, the raw materials are composed of the following materials by weight: 45 parts of high-density polyethylene resin powder, 22 parts of low-density polyethylene resin powder, 4.75 parts of high-strength glass fiber, 0.525 parts of special modified stabilizer, special modified filler Ingredients 11 servings.

[0069] The high-density polyethylene resin powder is 5000S high-density polyethylene resin produced by Daqing Petrochemical; the low-density polyethylene resin powder is DFDA-7042 linear low-density polyethylene.

[0070] The special modified stabilizer is a new generation of NX-2007 impact-resistant composite stabilizer produced by Weifang Naixin.

[0071] The high-strength glass fiber is a model CM10106G-45N high-strength glass fiber produced by Toray, Japan.

[0072] Special modified fillers include base material, lubricant and plasticizer; the mass ratio of base material, lubricant and plasticizer is 100:5:3;

[0073] The composition of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com