Warp afterwaxing device

A technology of warp yarn and wax roll, applied in liquid/gas/vapor yarn/filament processing and other directions, which can solve the problems of complicated operation and difficult to keep constant wax liquid amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

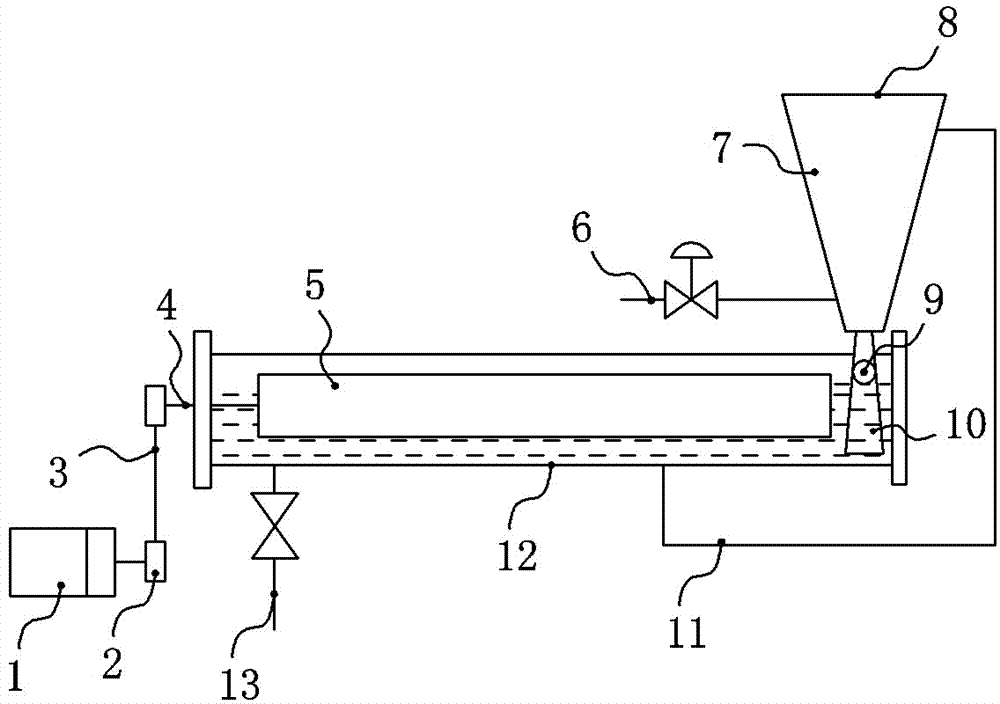

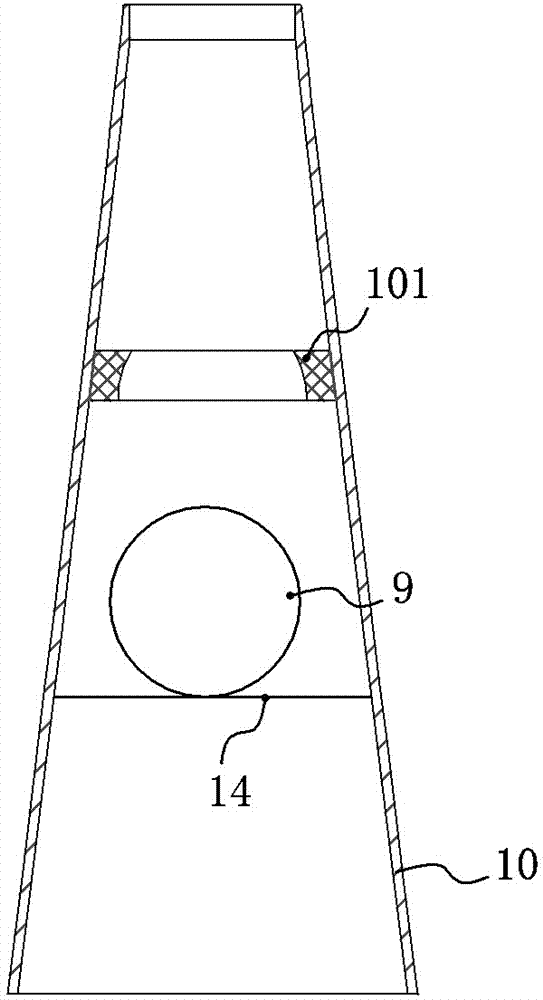

[0014] Such as figure 1 Shown, a kind of waxing device after warp, comprises wax tank 12, waxing roller 5, motor 1 and transmission shaft 4, waxing roller 5 is positioned at wax tank 12, and transmission shaft 4 is coaxially connected with waxing roller 5, The output shaft of the motor 1 and the drive shaft 4 are provided with a sprocket 2, and the two sprockets 2 are driven by the chain 3, wherein a wax melting bucket 7 with a wax bucket cover 8 is arranged above the wax tank 12, and the lower part of the wax melting bucket 7 There is a steam pipe 6, the upper part is provided with a steam return pipe 11 communicating with the bottom of the wax tank 12, and the bottom of the wax melting bucket 7 is provided with a liquid inlet pipe 10 extending into the wax tank 12, and the liquid inlet pipe 10 is flared from top to bottom shape, and it is provided with a floating ball 9 that can cooperate to close the liquid inlet pipe 10, such as figure 2 As shown, the liquid inlet pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com