Perpendicularity regulating method for foundation cast-in-place pile steel bar cage of power transmission iron tower

A technology of transmission tower and adjustment method, which is applied in basic structure engineering, sheet pile wall, building and other directions, can solve the problems of vertical deviation of steel cage, affecting the quality of pile body engineering, and no disclosed technology, etc., and achieves easy processing and high efficiency. Simple and clear assembly and mathematical relationships, and the effect of improving engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

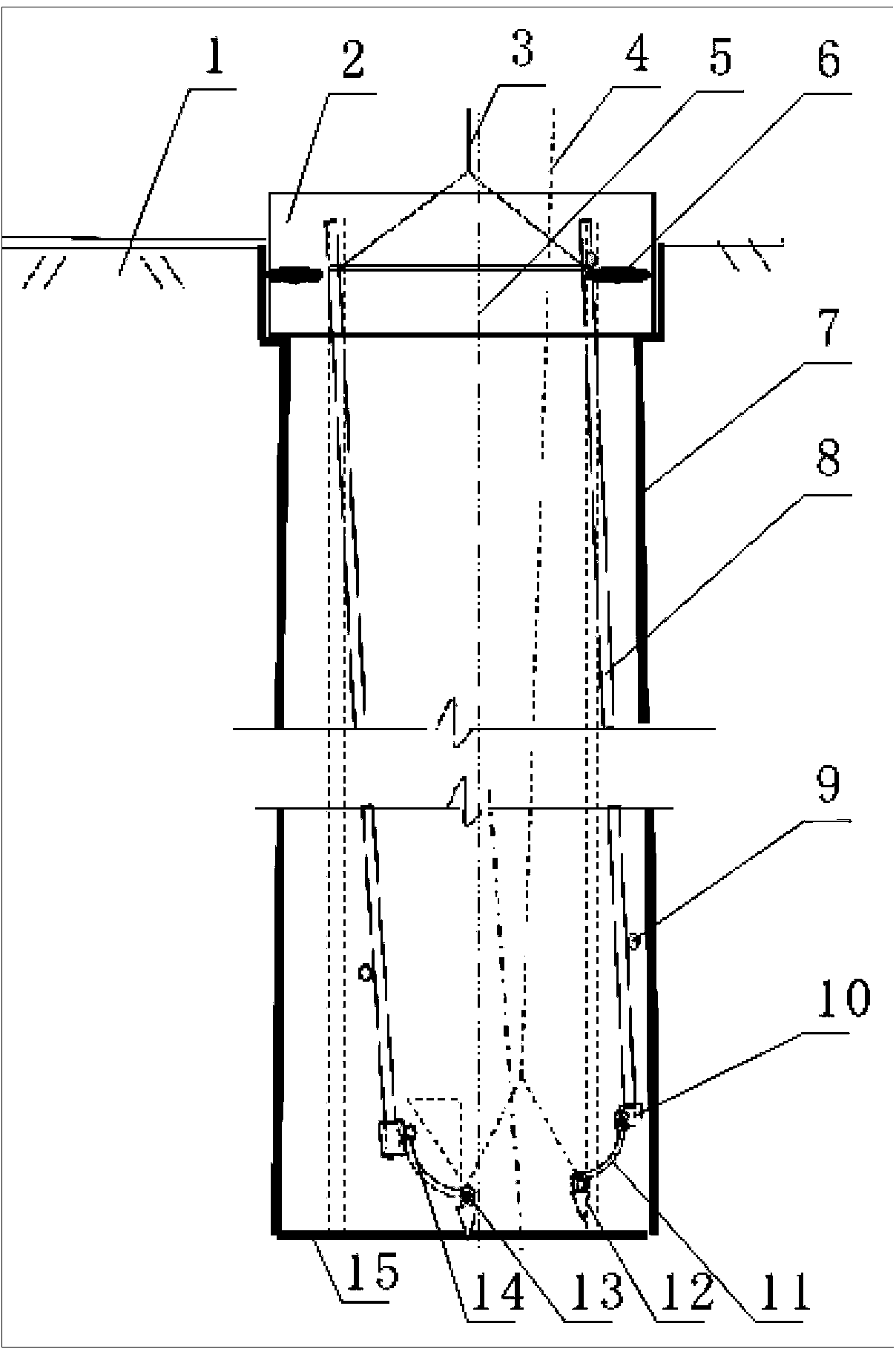

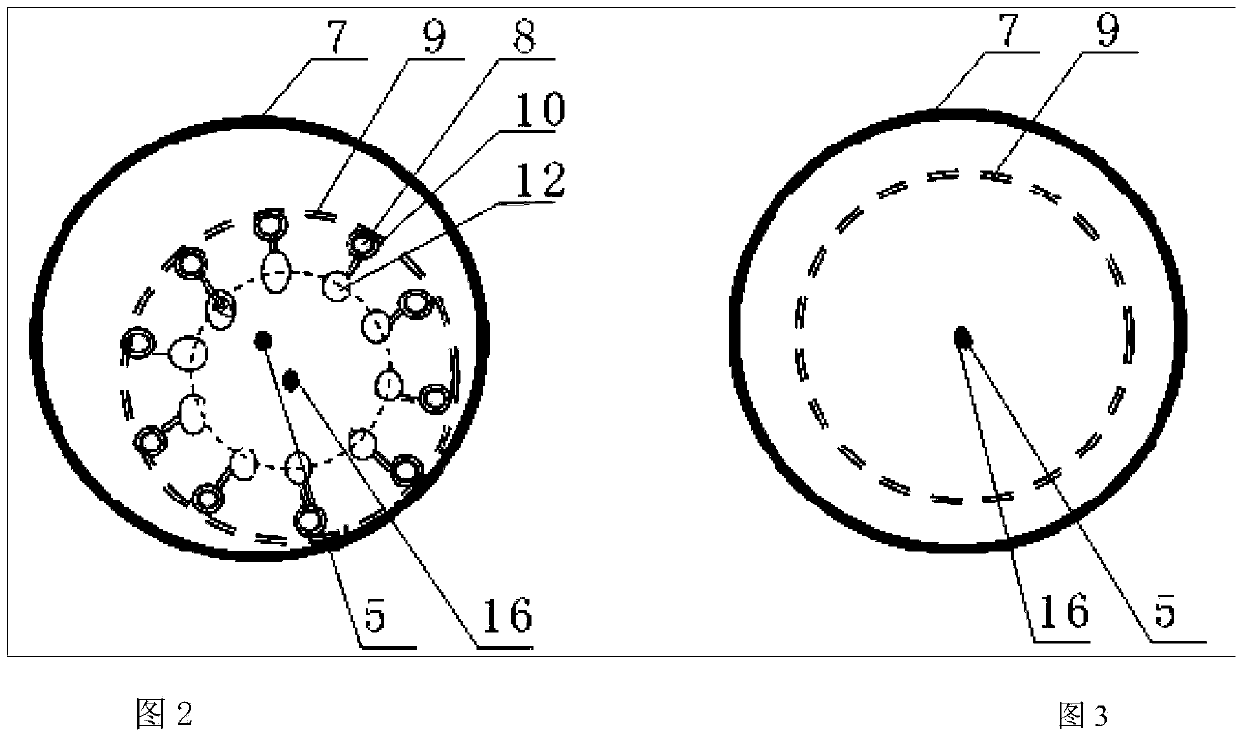

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0024] A method for adjusting the verticality of steel cages of cast-in-place piles for the foundation of power transmission towers. A borehole is formed in a ground 1 excavation well. The lower end of the borehole of the cast-in-place pile is hard soil at the bottom 15, and the side wall of the borehole of the cast-in-place pile is cylindrical. The cast-in-place pile forming hole wall 7, the upper end of the cast-in-situ pile forming hole is coaxially installed with a wellhead casing 2, and the upper end of the wellhead casing is higher than the ground;

[0025] A reinforcement cage is installed in the hole wall of the cast-in-place pile. The upper end of the reinforcement cage is connected with a sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com