Die supporting system for large deep pit steep slope surface cushion layer and supporting die casting construction method thereof

A technology for steep slopes and deep grooves, which is applied in the field of formwork support system and formwork pouring and ramming construction of the cushion on the steep slope surface of large-scale deep groove pits, can solve the problems of difficult construction of the cushion layer on the steep surface of large-scale deep pits, and achieve scientific construction methods, Good construction quality and smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

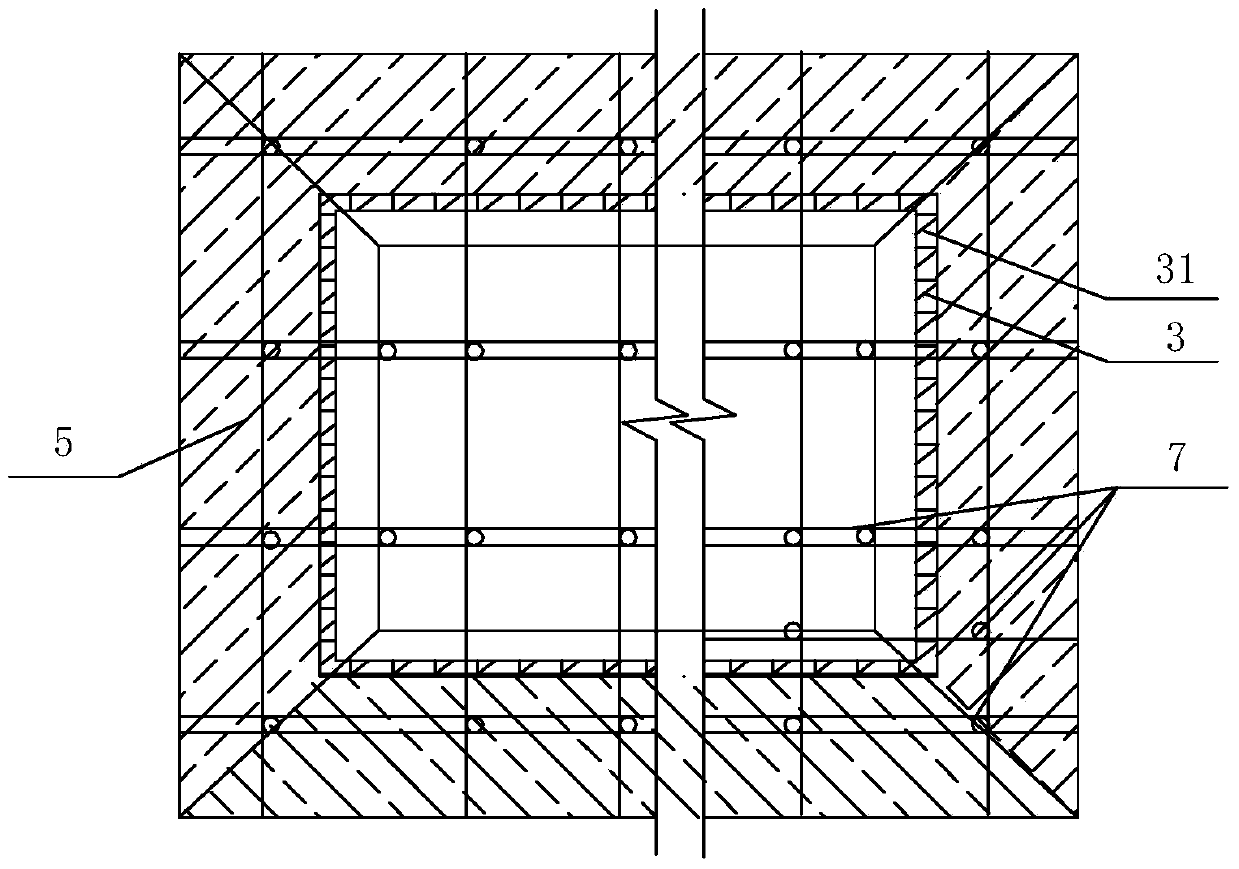

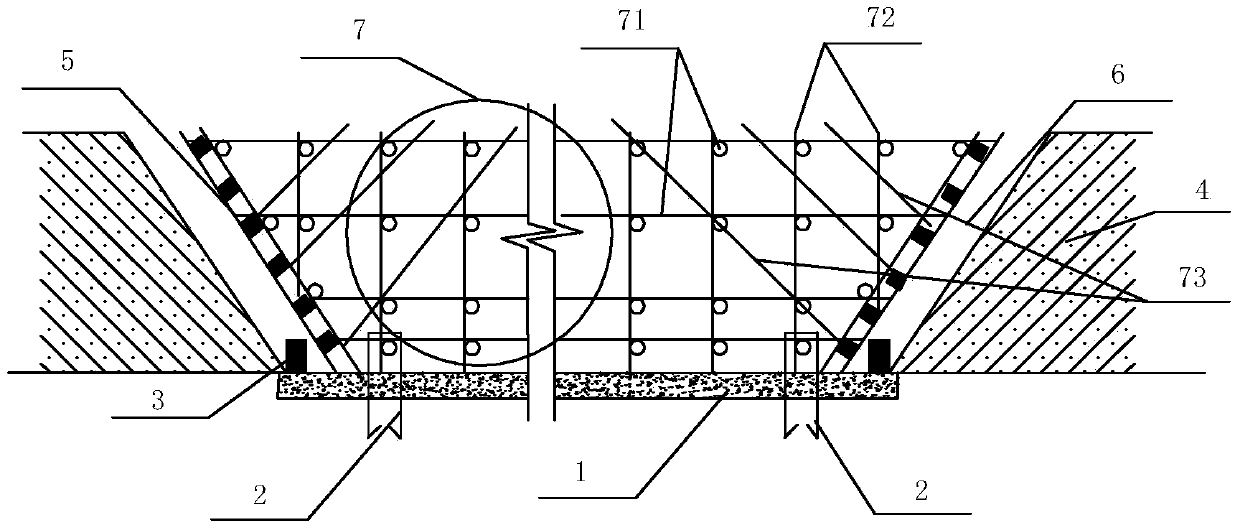

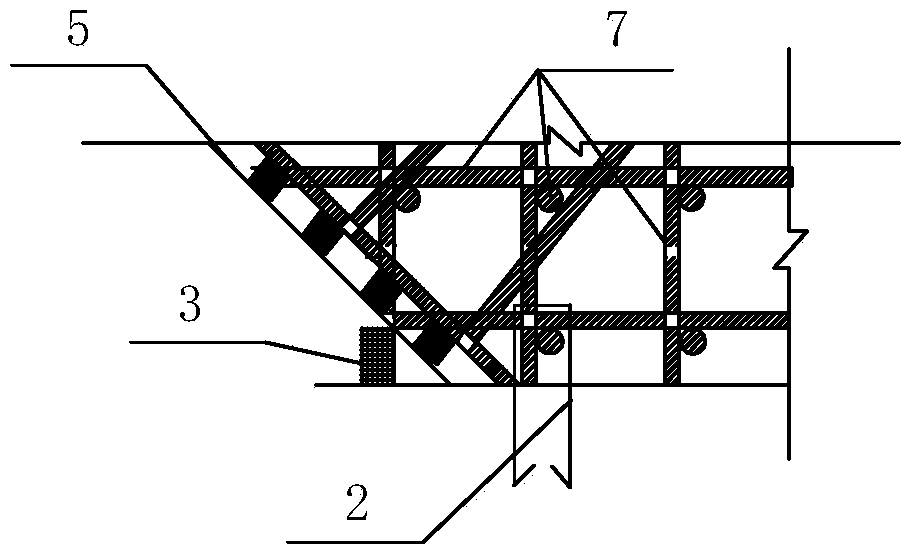

[0048] A formwork support system suitable for large-scale deep grooves and steep slope cushions, such as figure 1 , figure 2 As shown, the formwork system is an inverted quadrangular platform inner mold consisting of the bottom cushion 1 of the pit, the anti-floating steel bar 2, the formwork 5 and the steel pipe support frame 7; the bottom cushion 1 of the pit is located at the bottom of the pit The bottom is a leveled concrete formwork used to support the entire formwork system. The anti-floating steel bars 2 are pre-buried at the bottom of the pit and are integrated with the cushion layer 1 at the bottom of the pit; the steel pipe support frame 7 is composed of vertical and horizontal Horizontal steel pipes 71, vertical steel pipes 72 and reinforced scissors braced steel pipes 73 are formed. Fastener-type steel pipes are used to set up the steel pipes in the shape of an inverted quadrangular platform. The steel pipe support frame 7 is connected with the anti-floating stee...

Embodiment 2

[0064] A formwork pouring and tamping construction method suitable for large-scale deep grooves and steep slope cushions, which utilizes a formwork support system suitable for large deep grooves and steep slope cushions described in Example 1 to realize large deep grooves The method for formwork pouring and tamping construction of cushion on steep slope surface comprises the following steps:

[0065] A. Excavation and repair of earth and stone in the pit: Excavate the earth and stone according to the design size of the pit. When excavating, excavation needs to be carried out in layers. It is not possible to excavate to the bottom at one time, and the surface of the pit should be repaired in time;

[0066] B. Construction of pit bottom concrete cushion and pre-embedded anti-floating reinforcement: According to the construction plan, after the anti-floating reinforcement 2 used to connect the steel pipe support frame 7 is pre-buried at the bottom of the pit, pour and tamp the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com