Shearer cutting section with interchangeable motor and hydraulic drives

A cutting part and cutting part technology of a shearer, applied in cutting machinery, earthwork drilling and other directions, can solve the problems of large weight and volume of the cutting part, inconvenient disassembly and replacement, poor anti-torsion effect, etc. , to achieve the effect of light weight, convenient disassembly, and easy stepless speed regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

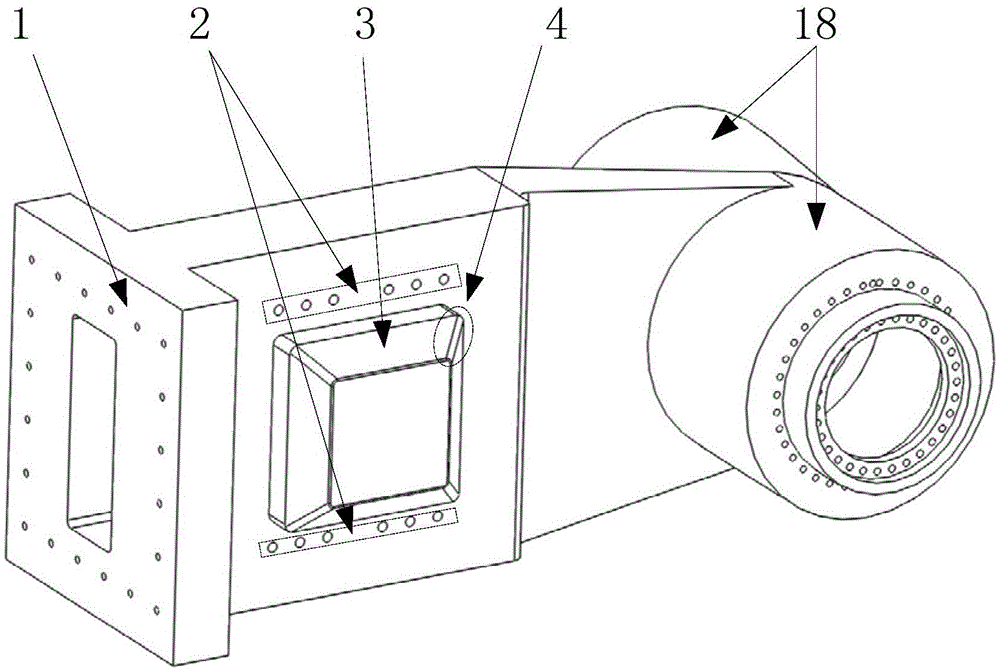

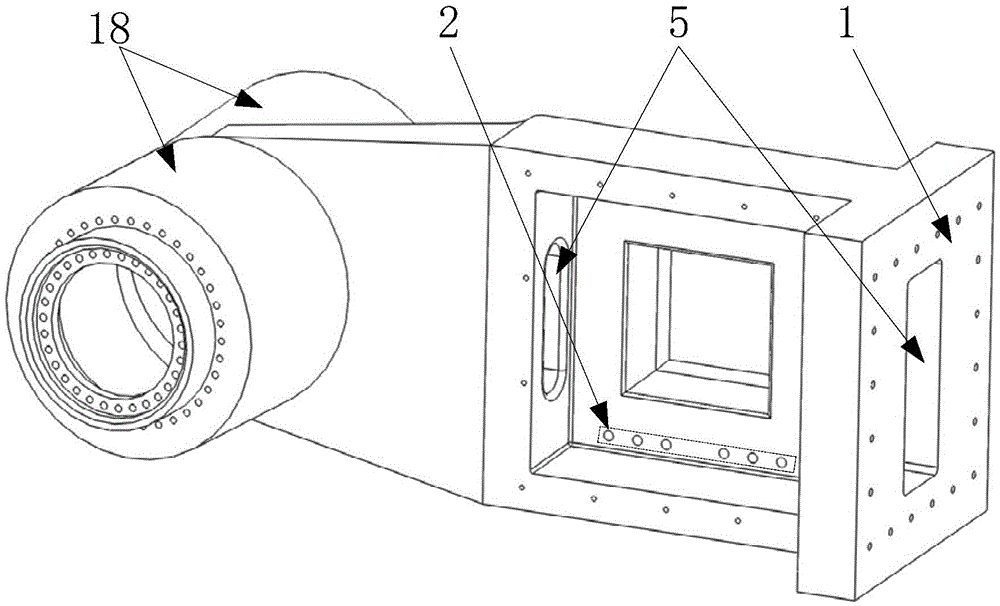

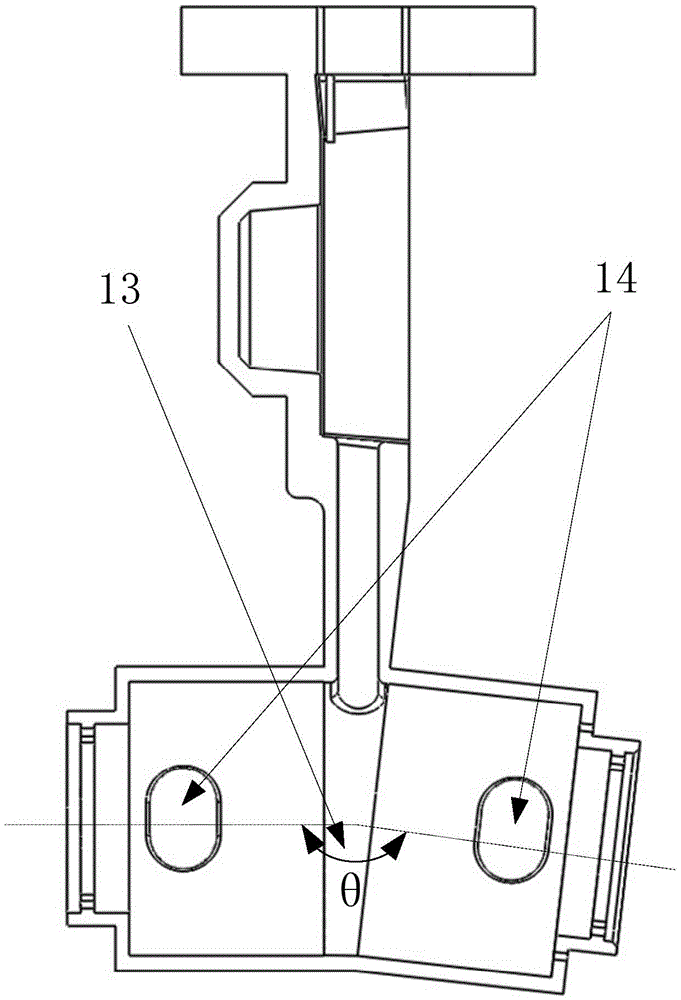

[0024] The present invention will be further described below in conjunction with accompanying drawing, with reference to accompanying drawing Figure 1-7 .

[0025] The specific implementation of the technical solution adopted by the present invention to solve the technical problems is illustrated by taking the cutting part of the LMGC-800 full hydraulic surface coal mining machine as an example:

[0026] A cutting part capable of electric and hydraulic drive interchangeability, including a hollow shell, the two sides of the front end of the shell are equipped with a left drum 12 and a right drum 12, the left drum 12 and the right drum 12 is provided with a pick tooth for cutting the coal seam, and the angle between the axes of the left drum 12 and the right drum 12 is less than 180 degrees; it is characterized in that:

[0027] The housing is in the shape of a narrow box, and the front end of the housing is provided with a left ear shell 18 for accommodating the left drum 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com