District cooling and heating transmission and distribution network health inspection system

A health inspection, transmission and distribution technology, applied in the field of inspection systems, can solve problems such as energy loss, inability to find timely and accurately, and achieve the effect of preventing energy loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

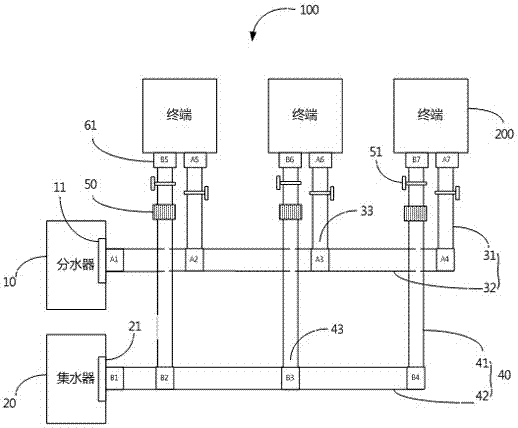

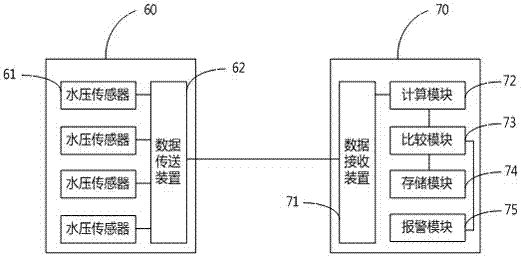

[0008] see Figure 1-2 , is a district cooling and heating transmission and distribution network health check system 100 provided in an embodiment of the present invention, which is connected to a plurality of terminals 200 . The terminal 200 may be a building or a chiller. The health inspection system 100 of the regional cooling and heating distribution pipeline network includes a water separator 10, a water collector 20, a water inlet pipe 30, a return water pipe 40, a plurality of filters 50, a plurality of electric control Valve 51 , a collection unit 60 and a monitoring center 70 .

[0009] The water separator 10 is a hollow container, which stores frozen water inside. The inside or outside of the water separator 10 is equipped with a first chilled water pump 11, and the first chilled water pump 11 is used to pump the chilled water stored inside the water separator 10 to the water inlet pipe 30. Describe the terminal 200. The positive pressure of the chilled water pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com