Full pre-mixing combustion type gas cooker

A gas appliance and fully premixed technology, applied in the fields of gas wall-hung boilers, gas appliances, gas stoves, and gas water heaters, can solve problems such as difficult popularization of products, non-compliance with environmental protection requirements, and air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

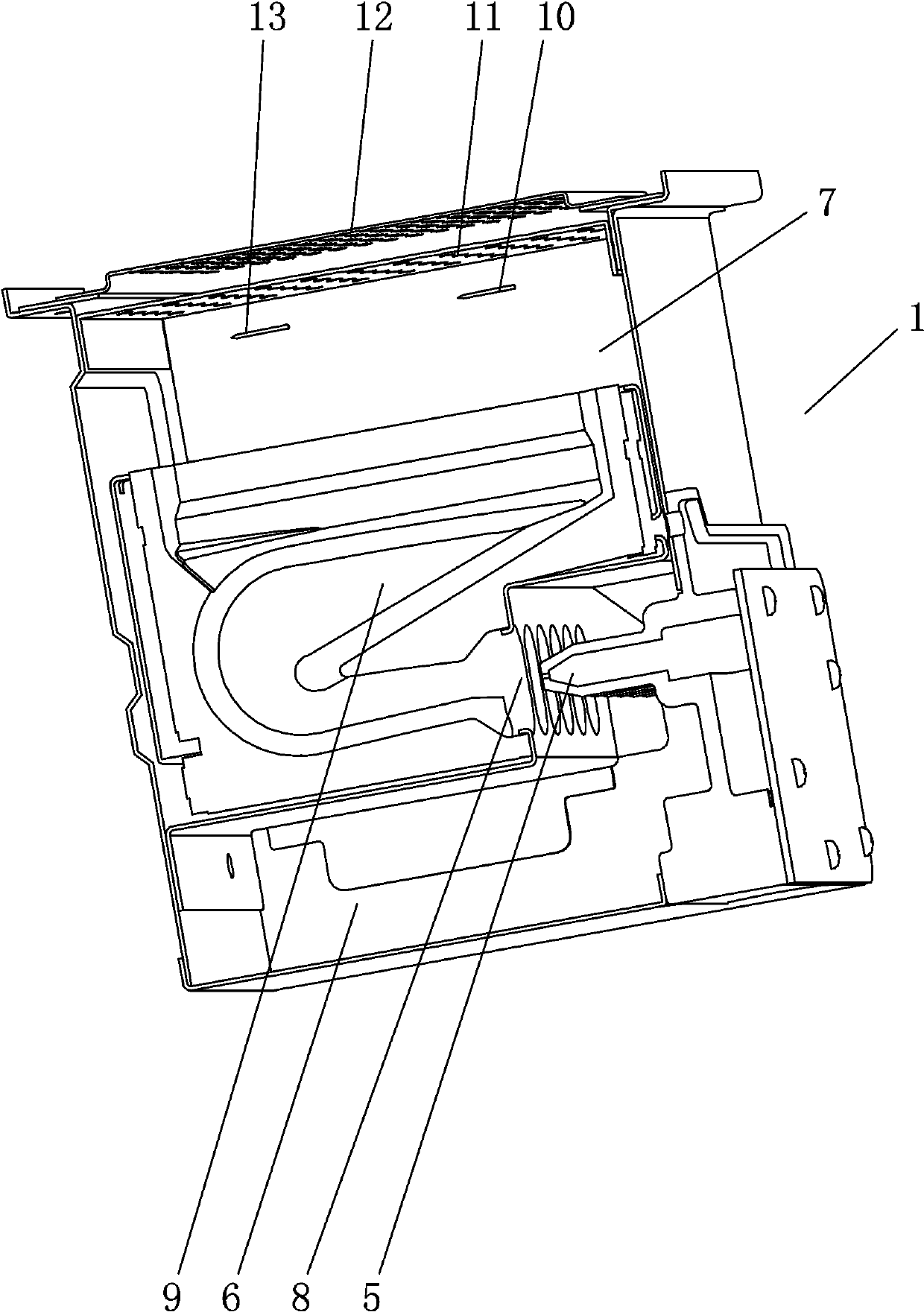

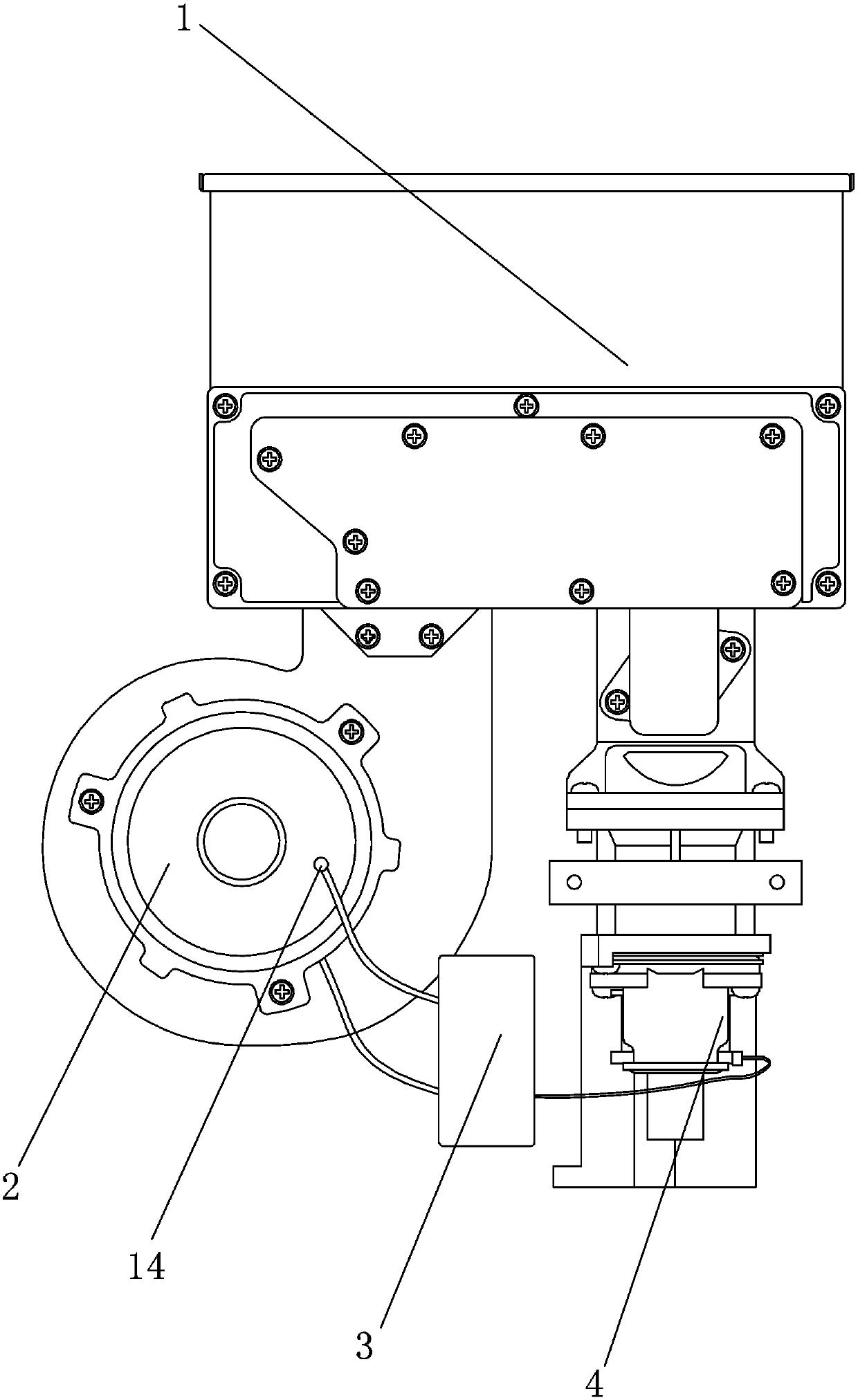

[0016] Such as figure 1 and figure 2 As shown, this embodiment includes a combustion device 1 for completely mixing gas and air, a DC fan 2, a controller 3, an electric control gas proportional valve 4 and a fan speed sensor 14, and the combustion device 1 and the fan 2 and gas proportional valve 4 The fan speed sensor 14 is installed on the fan 2, the controller 3 is electrically connected with the fan speed sensor 14, the fan 2 and the gas proportional valve 4, and the controller 3 synchronously adjusts the fan 2 and the gas proportional valve according to the feedback signal of the fan speed sensor 14 4 current increments and / or decrements.

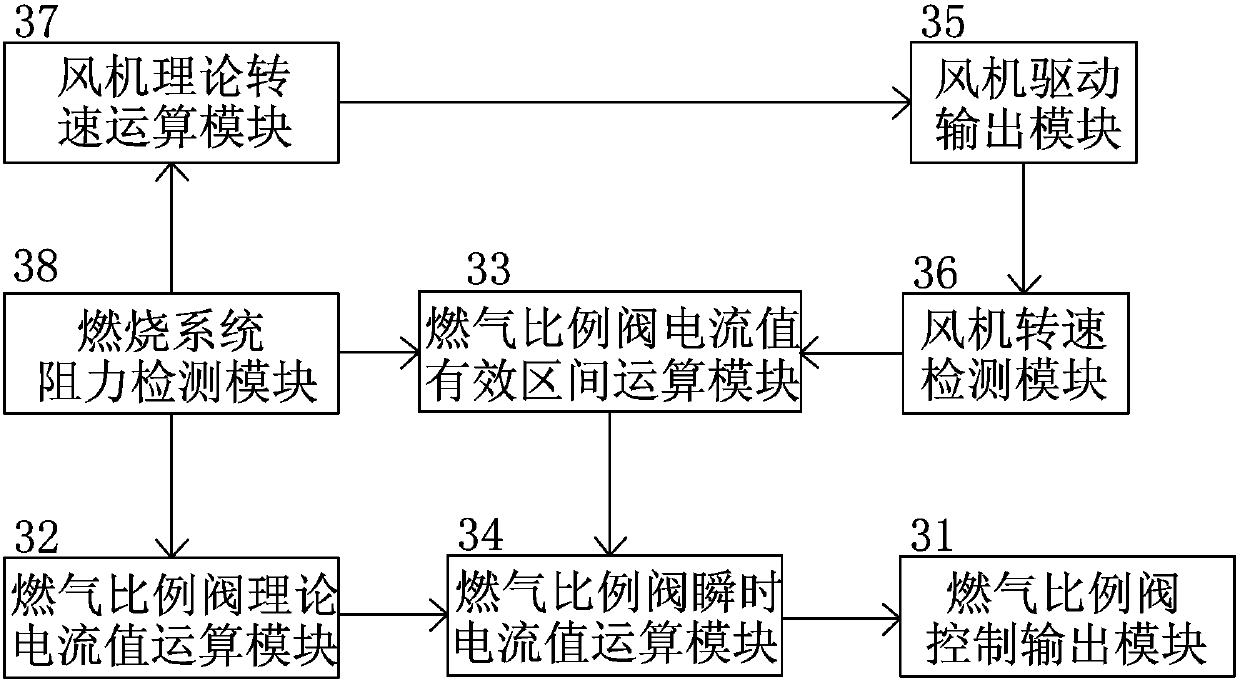

[0017] Such as image 3 As shown, the controller 3 includes a gas proportional valve control output module 31, a gas proportional valve theoretical current value calculation module 32, a gas proportional valve current value effective interval calculation module 33, a gas proportional valve instantaneous current value calculation mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com