Flexible touch-slip composite sensing array based on pressure-sensitive conductive rubber

A conductive rubber and composite sensing technology, which is applied in the field of composite sensing arrays, can solve the problems of not being able to detect contact force and slip signal at the same time, and unable to detect slip at the same time, so as to improve work stability, simple structure and simple method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with drawings and embodiments.

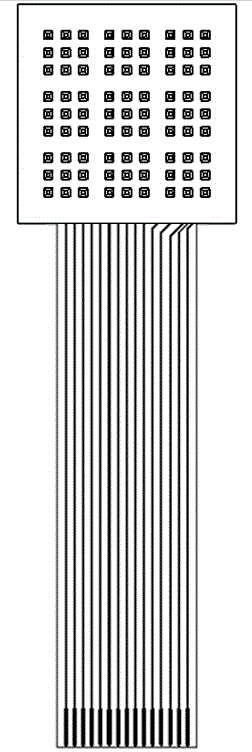

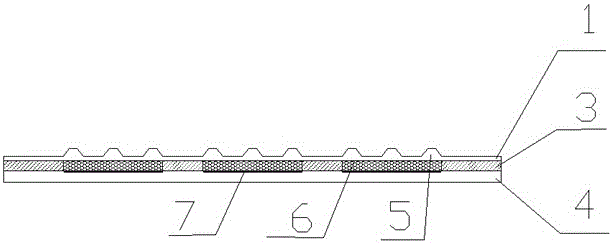

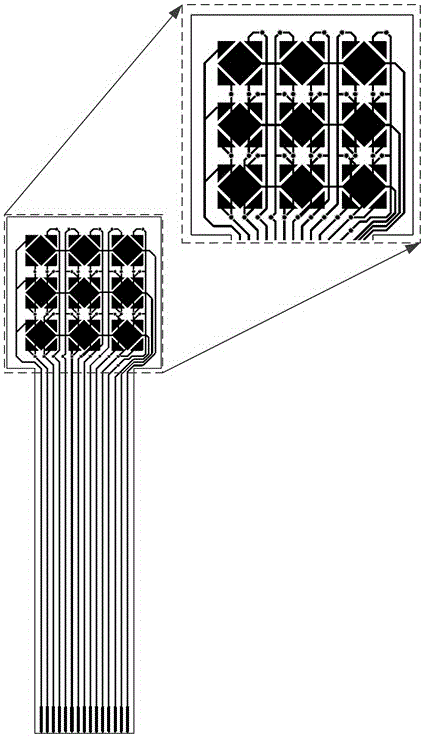

[0033] Such as figure 1 and figure 2 As shown, the present invention includes the flexible electrode layer 4 of the bottom layer, the middle layer and the top layer of the PDMS raised layer 1 closely attached from bottom to top; image 3 and Figure 5 As shown, the flexible electrode layer 4 directly below the conductive rubber unit 6 is provided with a test electrode group 7. The array distribution of the test electrode group 7 and the conductive rubber unit 6 is the same. The side lengths of the test electrode group 7 are the same; Figure 4 As shown, the middle layer includes a conductive rubber array 2 and a flexible filler 3 filled around the conductive rubber array 2, and the conductive rubber array 2 is an array formed of conductive rubber units 6; as Figure 5 and Figure 8 As shown, the PDMS convex layer 1 is provided with nine micro-protrusion structures...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com